WP CNC TURBO

2-axis CNC cleaner for PVC profiles

Automatic cleaning of the welding seam, with maximum configurability and productivity

Perfect if…

- Do you want to eliminate manual rework after welding?

- You need to automate the cleaning of the edges on PVC profiles.

- Are you looking for a car that can accommodate different frame sizes?

- Do you want a simple programming via DXF or barcode?

- You work both in standalone mode and on an automated line.

- Do you have coloured profiles or rounded corners to manage with dedicated tools?

Request the technical brochure now or speak with an expert.

Automatic cleaning of the welding seam, with maximum configurability and productivity

The WP CNC TURBO is a 2-axis CNC cleaner with brushless motors, designed to automatically clean the external weld seam on PVC frames, eliminating manual processes and ensuring flawless aesthetic results.

Thanks to the ability to operate in stand alone mode or integrated with 4-head welding machines, it is an extremely flexible solution for window frame manufacturers looking to automate the finishing of welded joints. The loading of programs via DXF files and management through GRAF Synergy software make the machine easy to program, even for inexperienced operators.

With a productivity of up to 200 pieces per shift, the WP CNC TURBO is the ideal choice for those seeking speed, precision, and digital integration in post-welding.

5 Reasons to Choose WP CNC TURBO

- Custom Automatic Cleaning. Configure each tool according to the profile to be treated: position, speed, and path are fully customisable.

- Intuitive interface with DXF. The software allows you to create programs directly from DXF files, reducing setup times and the possibility of errors.

- Immediate connection with welding line. The machine can automatically receive data from a 4-head welder, optimising the production flow.

- Adaptability to more complex profiles. Perfect cleaning even on rounded corners and coloured profiles, thanks to dedicated optional tools.

- Digital Integration. Compatible with TCP/IP network and equipped with a USB port: load and manage programs completely independently.

Product Details

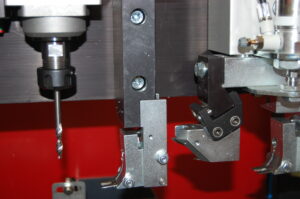

The WP CNC TURBO performs a comprehensive range of machining operations to ensure the aesthetic and functional cleanliness of welded corners.

Dimensions

Length: 1,900 mm

Width: 2,500 mm

Height: 2,000 mm

Weight: 1.000 kg

Performance

Productivity: up to 200 frames / 8h*

Operators required: 1

(*depending on the type and size of the profile)

power supply and Consumption

Installed power: 4.2 kW

Voltage: 400 V

Air consumption: 440 Nl/min

Minimum pressure: 7 bar

Workable profiles

Minimum frame size: 340 x 400 mm

Profile sizes: from 40×40 mm to 150×130 mm

Supported features and processes

- External cleaning of the corner with a blade.

- Removal using drills on specific areas

- Milling of internal and external gaskets

- Cleaning the exterior and interior of grooved profiles (white)

- Curved machining with upper and lower angle brackets

- Cleaning the internal corners on the glass stop and profile rebate.

Optional features and available configurations

Designed to meet every production requirement, the WP CNC TURBO can be customised with numerous options:

- Manual loading table with upper/lower protections (stand alone)

- Top/bottom grip rotating tables (Right/Left) for panels up to 2500×2500 mm

- Rounded knives (upper/lower) for rounded corners

- Specific tools for internal/external faces of coloured profiles

- Barcode reader for automatic profile recognition

- Complete knife set for coated profiles

Technology and automation

The heart of the WP CNC TURBO is the GRAF Synergy software, which enables detailed and intuitive programming:

- DXF management with settings for position, speed, and path for each tool.

- Loading programs via USB or TCP/IP network

- Speed and parameters fully adjustable from the interface.

- Integration with management systems and inline welding machines

- Ready for Industry 4.0 requirements: advanced traceability and connectivity

To explore the features of the WP CNC TURBO in more detail, request the complete brochure, a personalised quote, or a demo. Our technicians are available to help you find the ideal configuration for your production cycle.