TEST PRO DIGITAL

Testing machine for the tensile strength of welded PVC corners

Immediate verification of welding quality, with certified accuracy

Perfect if…

- Do you want to check the reliability of the welds of your PVC fixtures before shipping?

- You need an internal testing system for quality control.

- You produce custom window frames and want to certify every welded corner.

- Are you looking for a car that is easy to use yet technically advanced?

- You work with profiles of varying sizes and require operational flexibility.

- Do you want to document the tests for auditing or production traceability?

Request the technical brochure now or speak with an expert.

Check the integrity of welded corners with a quick, digital, and reliable test.

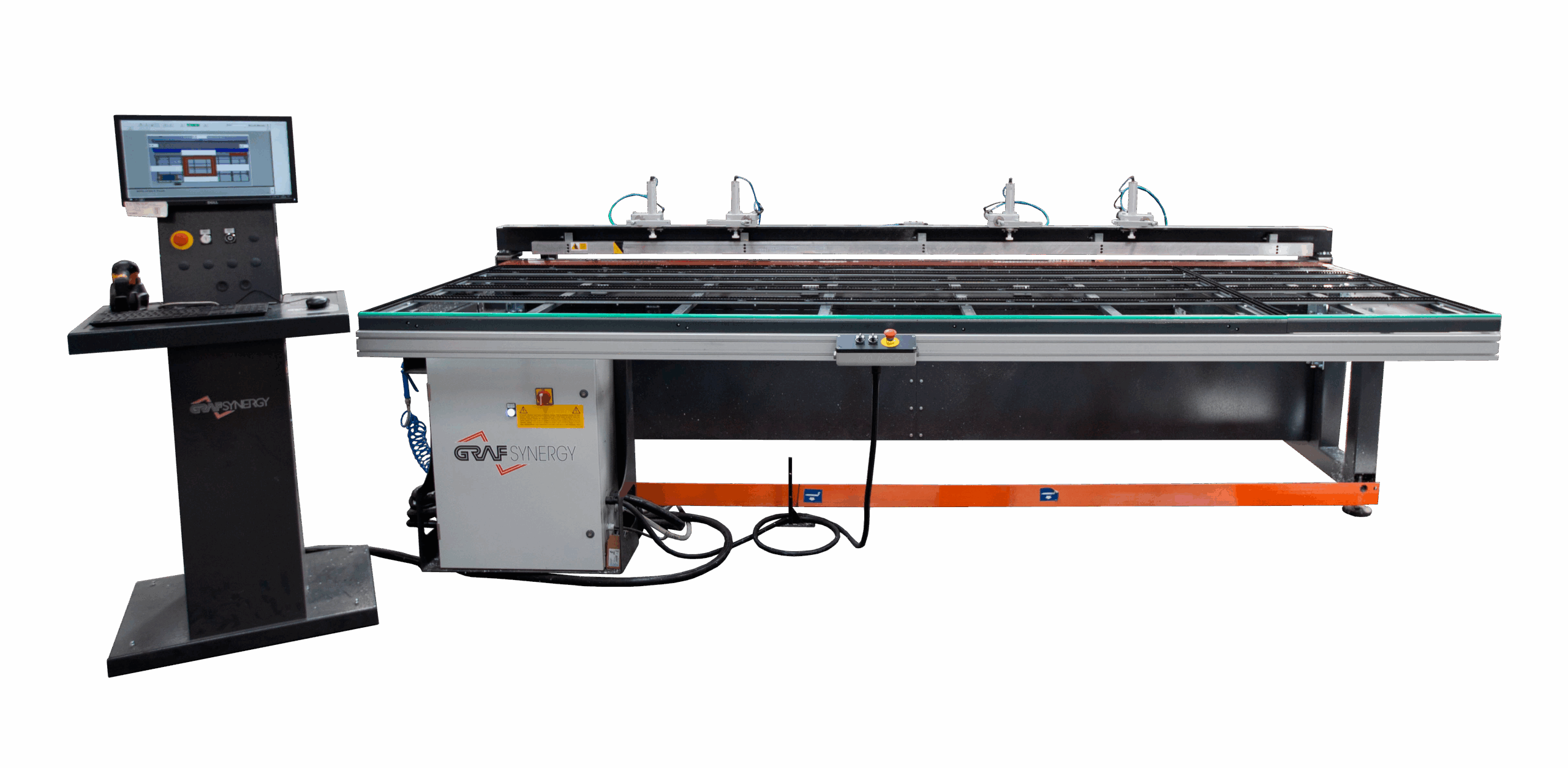

Test Pro Digital is the machine designed by GRAF Synergy to measure with extreme precision the breaking load on welded corners of PVC profiles, thereby ensuring a rigorous and replicable quality control in the production of window frames.

Thanks to a compact carbon steel structure and a hydraulic system with a certified load cell, it allows for standardized testing to be carried out directly in the workshop, eliminating the need for external laboratories.

The built-in graphic display allows for immediate data visualization and the export of results via USB.

5 reasons to choose Test Pro Digital

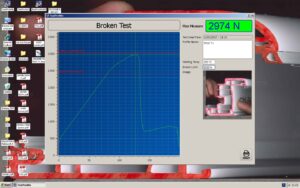

- Certified Precision and Digital Results. System with approved load cell for accurate measurements in Kg or Newton, with test graph displayed on screen.

- Total ease of use. Profile setup, test initiation, and result reading: all managed by a single operator.

- Immediate Break Load Analysis. A hydraulic piston applies a constant force on the welded joint until failure, highlighting the maximum peak.

- Wide range of testable profiles. Supports lengths from 350 to 740 mm, heights up to 600 mm, and thicknesses from 40 to 130 mm.

- Exportable digital reports. Test data can be saved to a USB drive, useful for internal checks or sharing with clients.

Product Details

Test Pro Digital allows for destructive testing to measure the mechanical strength of welded PVC corners. The test is conducted by applying a progressive force until the joint breaks, recording the maximum value achieved.

Dimensions

Length: 890 mm

Width: 575 mm

Height: 1,000 mm

Weight: 180 kg

Performance

Operations: manual

Operators required: 1

Testable angles/8h: variable

power supply and consumption

Installed power: 0.6 kW

Voltage: 240 Vac

Air consumption: n/a

Maximum force exertable: 1,000 kg

Workable profiles

Length: 350 – 740 mm

Height: up to 600 mm

Thickness: 40 – 130 mm

Supported features and processes

The graphical display interface allows for a visual analysis of the load behaviour throughout the entire cycle. The test results can be digitally stored for each tested profile.

Processes:

Measurement of maximum load capacity

Load test on welded corner

Optional features and available configurations

To meet every production requirement, Test Pro Digital can be equipped with:

- PC and integrated monitors with dedicated software and protocol key for connection with TestPro systems.

- Printer for the immediate generation of printed reports

These options allow for integration into quality management systems and traceability in Industry 4.0.

Technology and automation

Although it is a manual testing machine, Test Pro Digital employs advanced digital solutions for data acquisition and recording.

The certified load cell ensures reliable readings, while management via the digital display allows for immediate visual control.

Thanks to the optional features, the car can be connected to corporate information systems, making it compatible with the principles of Industry 4.0.

Contact the GRAF Synergy team

Request the complete brochure now or a dedicated consultation to understand how to integrate Test Pro Digital into your quality department.