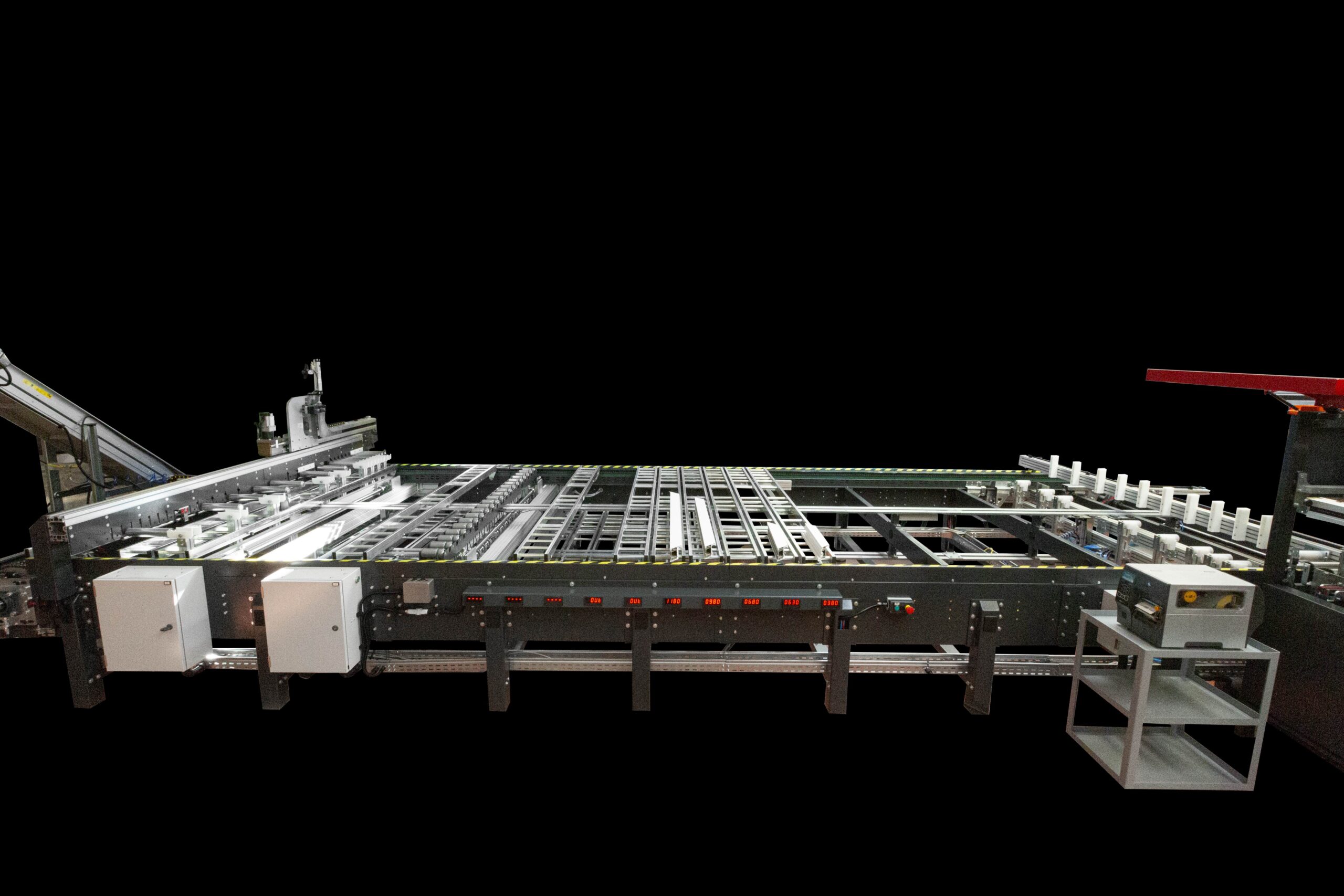

Tavolo dinamico

Automated connection unit for PVC window frame lines with metal reinforcement

Maximise production flow, eliminate waiting times, synchronise the machines.

Perfect if:

- Do you want to automate the connection between multiple machines with independent power supply?

- You must insert metal reinforcements without any errors or omissions.

- You need to optimise the space and work in a U or Z configuration.

- Are you looking for a solution that manages bidirectional loads and unloads?

- Do you want to integrate smart buffers to prevent machine downtime?

Request the technical brochure now or speak with an expert.

Optimize the space and productivity of your line with an intelligent bar handling system, perfect for the continuous feeding of the screw fastening centre.

The Dynamic Table is a modular connection unit designed to fully automate the advancement of profiles towards the ASG-E screw centre. Thanks to the system with autonomous handling trays, each bar advances only when completed, ensuring a constant and uninterrupted flow.

Perfect for production lines working with PVC and iron in parallel, the Dynamic Table also functions as a buffer, synchronising multiple machines in U or Z configurations without dependency constraints.

The ideal solution for those looking to eliminate bottlenecks between processing stages, maintain high productivity, and reduce machine downtime.

5 reasons to choose the Dynamic Table

- Dual function: buffer + docking station. Each bar moves independently only when ready: no more empty spaces, maximum efficiency between connected machines.

- Intelligent Reinforcement Detection. The system identifies whether metal reinforcement is necessary, indicates its size and code, and halts progress until the correct installation is completed.

- Connection Versatility. It can connect multiple machines, even with exhausts in opposite directions and customised layouts (U-shaped or Z-shaped).

- Completely customisable. Adjustable in length, width, number, and type of trays to meet any production requirement.

- Continuous Efficiency. It reduces downtime between phases, prevents stoppages, improves flow, and perfectly synchronises the rhythms of the line.

Product Details

Optimize the space and productivity of your line with an intelligent bar handling system, perfect for the continuous feeding of the screw fastening centre.

Dimensions

Length: 8,000 mm (extendable up to 14,000 mm with optional modules)

Width: 2,500 mm (also available in a 4,000 mm version)

Height: 800 – 1,000 mm (adjustable)

Weight: 3.200 Kg

Performance

Productivity: depends on connected machines

Required operators: 1

power supply and Consumption

Installed power: 2.2 kW

Voltage: 400 V

Air consumption per cycle: 180 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Length: from 500 to 5,000 mm

Height: from 130 to 180 mm (varies depending on the type)

Supported features and processes

The Dynamic Table stands out for its operational intelligence in managing the advancement of the bars based on the actual state of processing. Each tray is equipped with autonomous movement, a dedicated display, and detection sensors for the presence and size of the metal reinforcement.

Main Processes

- Automatic single bar advancement

- Presence detection reinforcement

- Progress blockage in the absence of reinforcement

- Identification of size and iron code

- Bar management of leftovers

Optional settings and configurations

Extremely modular, the Dynamic Table adapts to any production layout, offering a wide range of customisations:

- Additional modules from 2,000 mm for extension up to 14,000 mm

- 200 mm steel trays (available in both widths: 2,500 mm and 4,000 mm)

- Width configuration 4,000 mm for higher load requirements

- Integration with automated roller conveyors for alignment and reordering of bars.

TECHNOLOGY AND AUTOMATION

Equipped with smart sensors and dedicated displays, the Dynamic Table represents a fully integrable system within an automated line. Ideal for the feeding of the ASG-E centre, it synchronises with the speed of the line, preventing machinery jams in the event of misalignment.

Compatible with the principles of Industry 4.0, it can be equipped with systems for remote monitoring and interfacing with management software.

Contact us to find out if the dynamic table is the right solution for your production.