STEEL CONNECT

CNC cutting centre for PVC metal reinforcements

Maximum efficiency in cutting and recovering metal reinforcements: less waste, more sustainability, perfect synergy with PVC

Perfect if you want…

- Automate the cutting of metal reinforcements for PVC profiles

- Recover metal offcuts and reduce raw material costs

- Synchronize reinforcement cutting with profile cutting

- Ensure precise and continuous cuts with blade wear monitoring

- Minimize downtime and manual intervention

Request the technical brochure now or speak with an expert.

Maximum efficiency in cutting and recovering metal reinforcements: less waste, more sustainability, perfect synergy with PVC

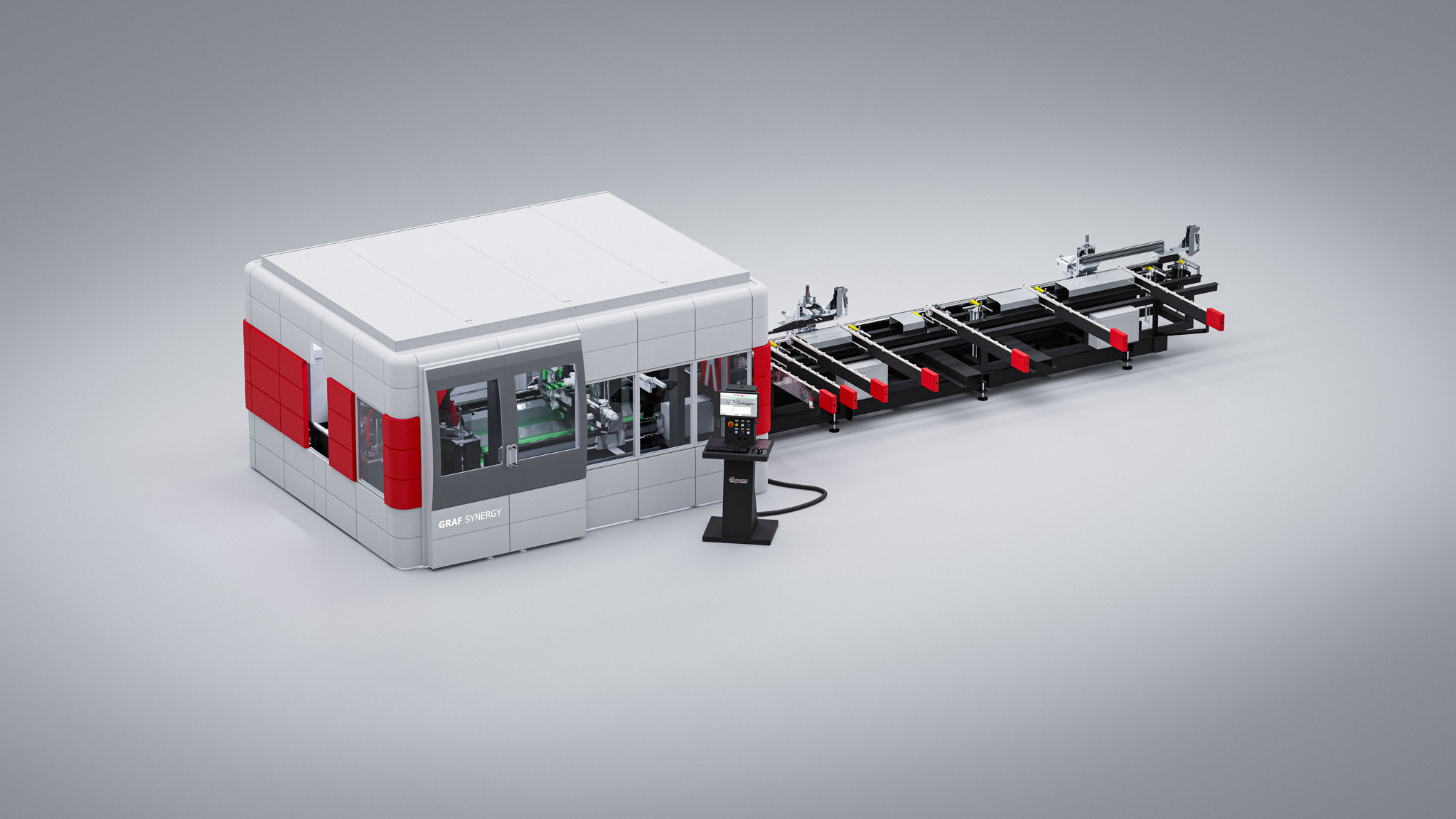

STEEL CONNECT is the high-performance CNC cutting centre designed to automate and optimise the production of internal steel reinforcements in PVC profiles. Equipped with a Ø350 mm descending blade with controlled movement, it combines precision, continuous production, and electronic tool wear monitoring for consistently perfect cuts.

Thanks to its compatibility with GRAF Synergy PVC cutting centres, STEEL CONNECT enables synchronized and centralised production, managed through advanced software for importing and optimising cutting lists.

With the addition of the optional CONNIE module, it transforms into an automated welding centre for metal scraps, drastically reducing waste and making the recovery of previously unused materials economically viable.

5 reasons to choose STEEL CONNECT

- Fast and reliable cutting. Reduces execution times thanks to controlled downward movement and integrated software.

- Synchronized production. Operations fully integrable with GRAF Synergy PVC cutting and processing centers.

- Intelligent scrap recovery. With the CONNIE module, metal offcuts are welded to optimize material usage.

- Advanced electronic control. Blade speed and wear are electronically managed for consistent results and longer tool life.

- Intuitive interface and flexible configurations. Easy-to-use software suitable even for inexperienced operators, with a wide range of available options.

Product Details

STEEL CONNECT is a fully automated CNC cutting centre, consisting of:

- Loading module:

Automatic magazine for 10 bars, loading via chains, rack-and-pinion pusher with brushless motor. - Cutting module:

1 Ø350 mm blade with controlled, constant downward movement for high-precision 90° cuts. - Unloading module:

Pneumatic extractor on steel table with photocells, configurable on both sides. Capacity up to 10 pieces.

Dimensions

Length: 14,900 mm

Width: 3,400 mm

Height: 2,800 mm

Weight: 2,500 kg

Performance

Up to 1,800 cuts/8h* (*depending on the type of metal and machine configuration)

Operators required: 1

power supply and Consumption

Installed power: 10 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption per cycle: 200 Nl/min

Workable profiles (automatically)

Length: 700 – 6,000 mm

Width: 20 – 80 mm

Height: 20 – 60 mm

Possible processes

90° cut on metal reinforcements

Alignment of sections for automated welding (with CONNIE module)

Optional available

STEEL CONNECT can be equipped with a range of options to further enhance productivity, flexibility, and sustainability:

- Fly Optimizer: automatic detection of bar remnants and list optimization

- Ø550 mm blade with clamp kit for profiles up to 180 mm

- Electronic speed control on controlled axis

- Extended unloading table (up to 5,000 mm)

- Labeling machine for automatic part identification

- Extended cutting-unloading axis to reduce downtime

- Soundproof cabin

- CONNIE module for welding metal offcuts

- Laser for marking or tool monitoring

Contact us to discover how STEEL CONNECT can transform your production

Request the brochure or a consultation with a GRAF Synergy expert now. Efficiency, sustainability, and innovation are already in operation.