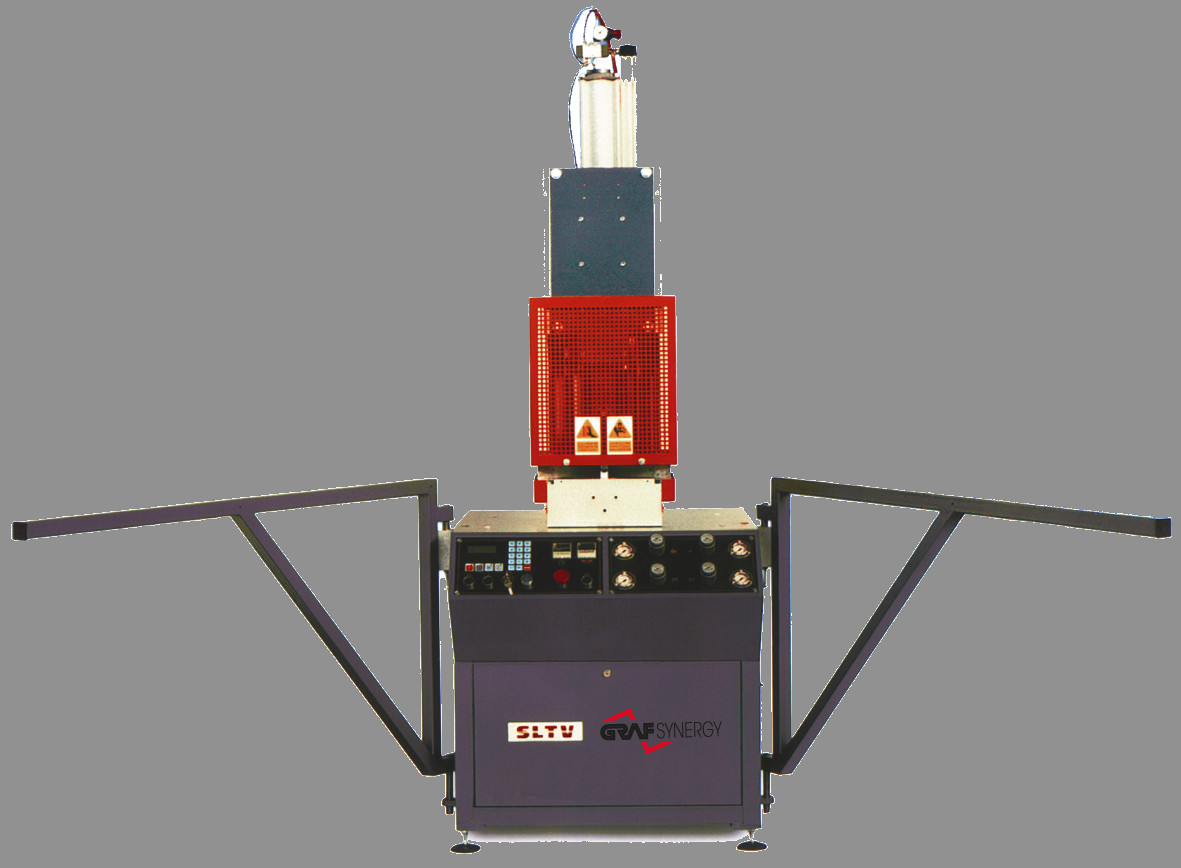

SLTV

Universal single-head welder for T-joints, crosses, and variable angles

Maximum flexibility, absolute precision: the ideal choice for complex PVC joints

Perfect if:

- We create complex frames or special shapes such as cross joints, ‘T’ joints, or ‘H’ joints.

- You need variable angles, even exceeding 90°, while maintaining tight tolerances.

- Do you want to reduce operator intervention through an automated cycle?

- Are you looking for a compact yet professional machine, suitable for specialist productions as well?

- You need a quick change of templates for diverse processing tasks.

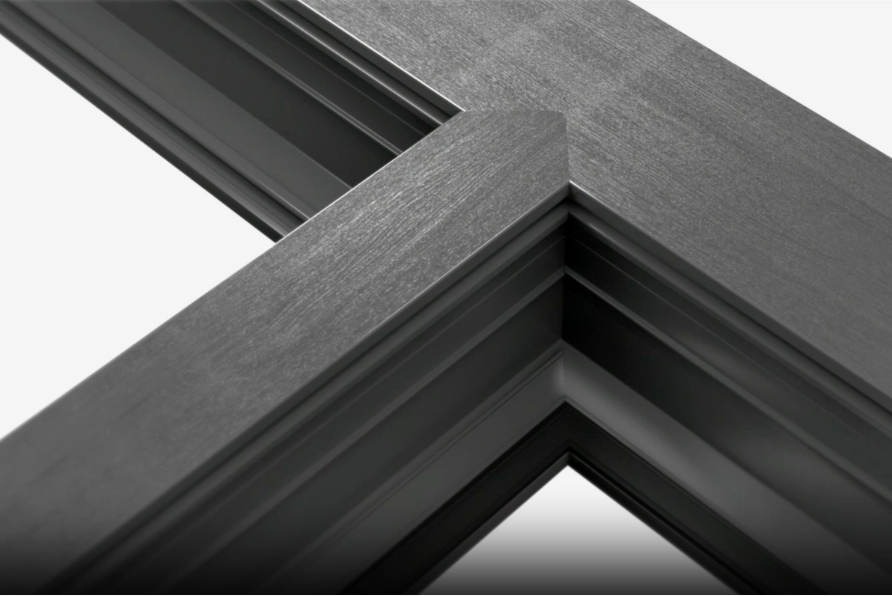

- Produce custom pieces for unconventional architectures or non-standard windows.

Request the technical brochure now or speak with an expert.

Maximum flexibility, absolute precision: the ideal choice for complex PVC joints

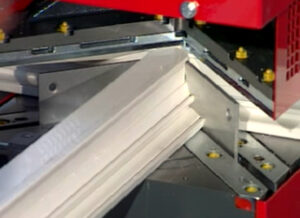

The SLTV from Graf Synergy is a single-head welding machine designed to offer maximum versatility for the most technical and complex operations. Thanks to its variable angle head, it allows for corner welds ranging from 35° to 180°, including configurations such as ‘T’, cross, or ‘H’ (notch welding). The fully automated cycle ensures consistency, repeatability, and a reduction in errors, even with pointed cut profiles and V-grooved workpieces. It is ideal for manufacturers looking to expand their range of fixtures while providing a highly customised service.

5 Reasons to Choose the SLTV Sliding Horizontal Table

- Weld every geometry, without compromise. The only single-head welder capable of welding at variable angles from 35° to 180°, including cross, ‘T’, and ‘H’ joints. Perfect for special or architectural productions.

- Guaranteed dimensional accuracy. Every corner maintains the exact settings: consistent quality, with no rework or waste.

- Fully automated cycle. Integrated electronic control that regulates temperatures, timings, and alerts for any operational anomalies.

- Quick-release welding fixtures. An intelligent mechanical system for quickly replacing welding fixtures, reducing setup time.

- Integrated display for intuitive control. Easy and immediate management thanks to the onboard electronic interface: less margin for error, more efficiency.

Product Details

Pensata per soddisfare anche le esigenze più specifiche, la SLTV è una saldatrice versatile che amplia la gamma di prodotti realizzabili nel tuo impianto. La possibilità di saldare angoli speciali e giunzioni complesse la rende un asset prezioso per officine che offrono serramenti personalizzati o per chi vuole aumentare il valore percepito del proprio catalogo.

Sizes

Length: 1,250 mm

Width: 920 mm

Height: 2,300 mm

Weight: 350 Kg

power supply and Consumption

Installed power: 3.6 kW

Voltage: 230 V single-phase

Air consumption per cycle: 45 NI/min

Operating pressure: 7 bar

Performance

Automated cycle with electronic management

Operator manual mode for initial settings

Operators required: 1

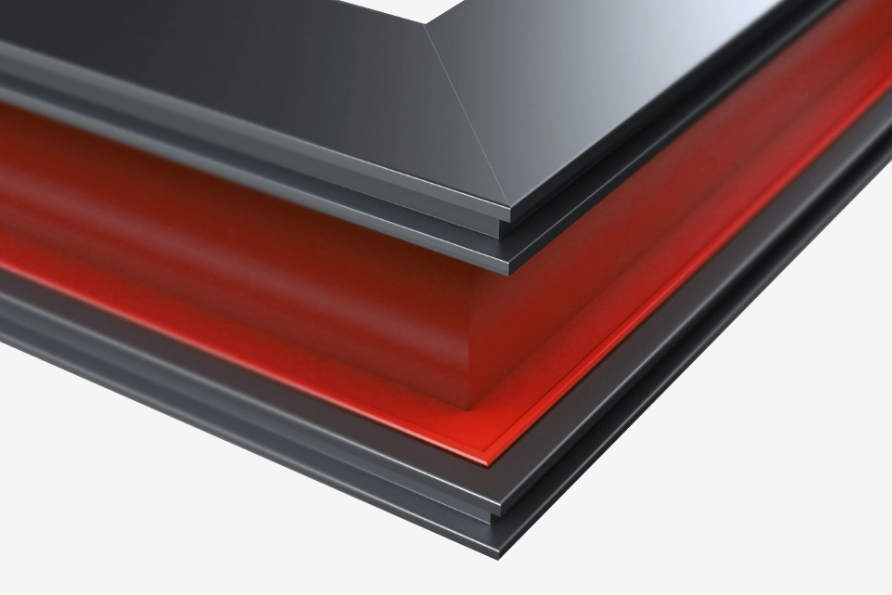

Weldable profiles

Profile height: 40 to 200 mm

Profile width (at 90°): 40 ÷ 130 mm

Variable values depending on profile type, speed, and curb size.

Supported features and processes

- Variable angle welding (35°-180°)

- T-joints

- Cross welds

- Notch welding (“H”)

- Welding pointed cross members with a backing piece and a ‘V’ groove.

Optional available

To expand operational possibilities, the SLTV can be customised with:

- Custom counter shapes tailored to customer designs (e.g. for two-piece joints)

- Interface with measurement systems or pre-cutting (upon request)

- Dedicated configurations for special profiles

The machine is also designed to be integrated into modular lines or dedicated work cells.

TECHNOLOGY AND AUTOMATION

The technological heart of the SLTV is the integrated control system that measures welding parameters in real-time, checks for any anomalies, and promptly alerts for any necessary interventions. This ensures production continuity, reduces waste, and enhances operational safety.

- Electronic control with display

- Temperature Regulation of Plates and Limiting Blades

- Preparedness for Industry 4.0 management (upon request)

- Automatic time/temperature management system

Contact us to find out if the SLTV is the right solution for your production.