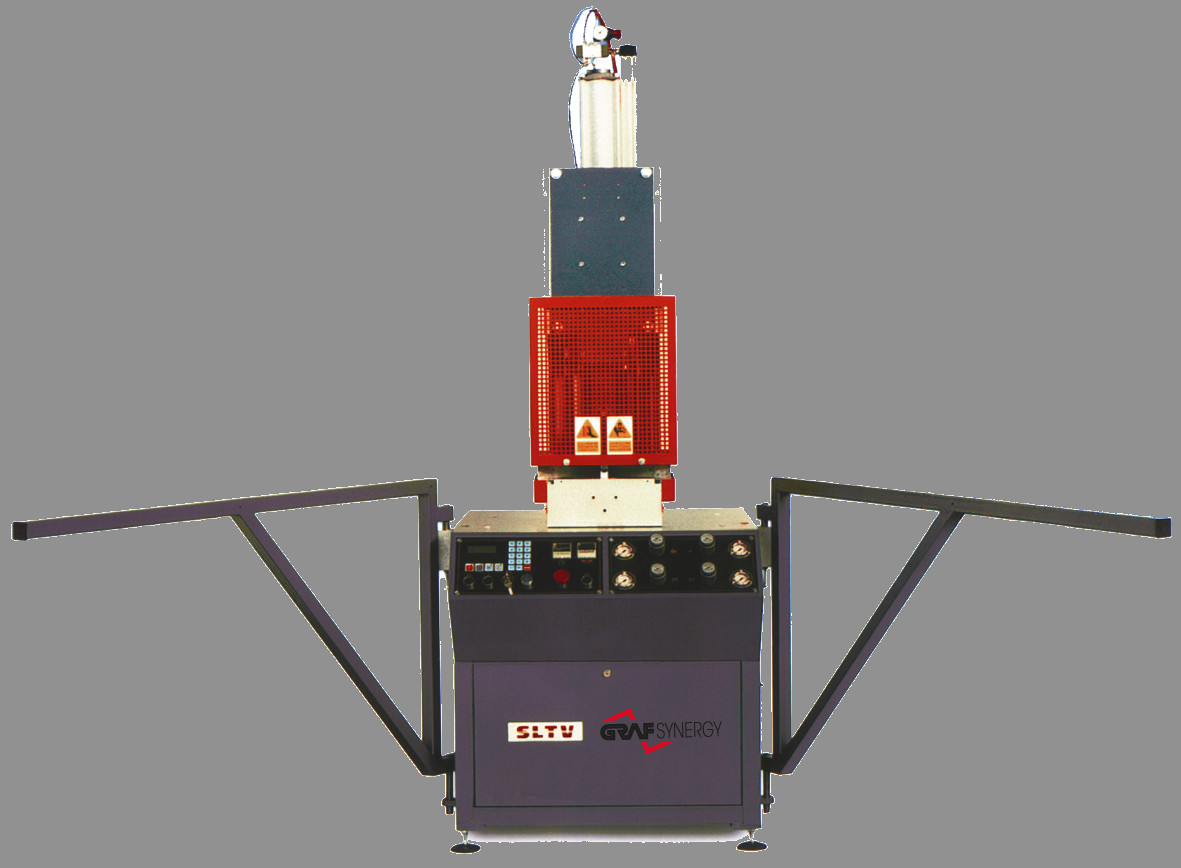

SLS

Single-head CNC welder for PVC thresholds and special profiles

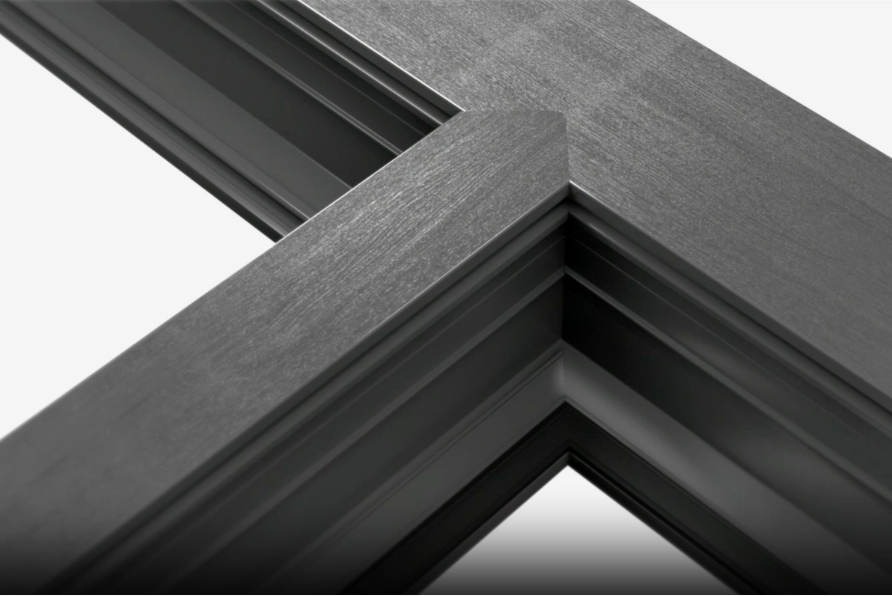

V-Perfect welding on any type of coating, without cleaning or reworking

Perfect if:

- You need to weld visible thresholds or corners where aesthetics are essential.

- Use film-coated or painted profiles that cannot be reworked.

- Do you want to completely eliminate the post-welding cleaning phase?

- You work with non-weldable materials inside the profiles (fibre, metal).

- You need a compact solution, perfect for small spaces as well.

- Do you want to maximise automation while maintaining flexibility in your components?

Request the technical brochure now or speak with an expert.

V-Perfect welding on any type of coating, without cleaning or reworking

SLS is the world’s first single-head CNC welder specifically designed for the perfect junction of thresholds between walls and frames. Thanks to the exclusive V-Perfect technology, patented by Graf Synergy, it completely eliminates the welding bead, achieving flat and uniform surfaces without the need for finishing. The machine is ideal for working with complex profiles, whether painted or laminated, featuring non-weldable internal inserts (fibreglass, aluminium, resin), offering maximum production flexibility with just one operator.

5 reasons to choose SLS

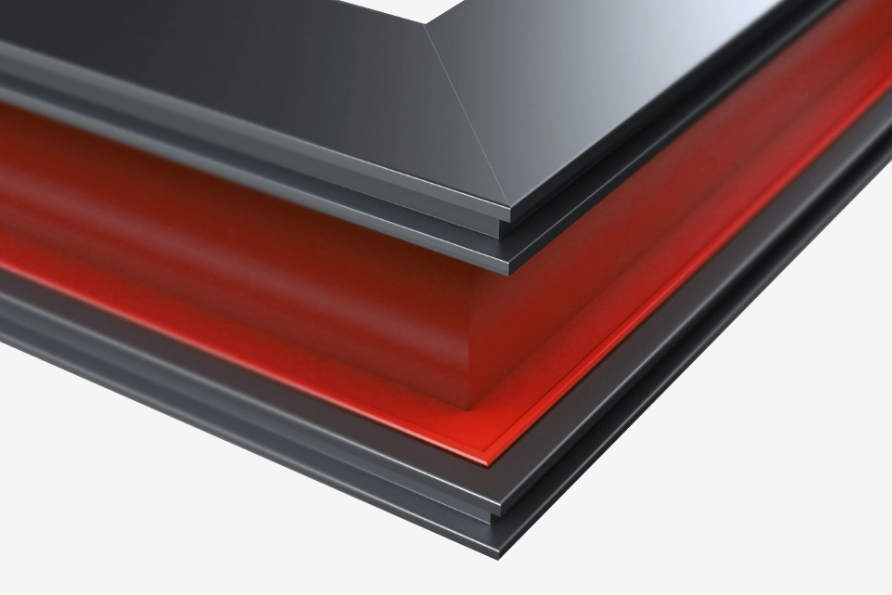

- Perfect welding, without seams or touch-ups. Thanks to V-Perfect technology, the welded angle is clean, uniform, and free of visible joints, even on decorative or coated profiles.

- Compatible with all types of coatings. Anodised aluminium, painted PVC, natural wood, acrylic: SLS guarantees the same precision and finish on every material.

- Significant reduction in production time and costs. No rework, no cleaning, no parts rotation table: a complete cycle every 140 seconds with just one operator.

- Compact size, maximum efficiency. Just 3×3.5 metres: the machine is ideal for compact production layouts, without compromising on performance and quality.

- Automatically compensates for tolerances. An intelligent automatic calibration system that adjusts the cycle to the dimensional differences between profiles, maintaining impeccable aesthetics.

Product Details

SLS was created to meet the needs of those who produce high-quality aesthetic windows. Every weld is perfectly integrated into the profile, even when dealing with complex materials and delicate coatings. The result: designer windows ready without any additional steps.

Dimensions

Length: 3,000 mm

Width: 3,500 mm

Height: 2,100 mm

Weight: 1.300 kg (including operational space)

Performance

Up to 1 weld every 140 seconds

Minimum weldable size: 400 mm (variable)

Operators required: 1

power supply and Consumption

Installed power: 17 kW

Voltage: 400 V

Air consumption per cycle: 600 NI/min

Operating pressure: 7 bar

Weldable profiles

Profile height: 30 ÷ 60 mm

Profile width (at 90°): 60 ÷ 220 mm

No maximum weldable side limit due to the machine

Supported features and processes

- Welding thresholds and lower joints

- V-Perfect angles on special profiles

- Welding without rework

- Precise profiling even on acrylic coatings

Optional settings and configurations

The SLS can be equipped with accessories to optimise productivity according to your workflow:

- Built-in vacuum for a clean workspace management

- Custom configurations for existing lines or specific layouts

- Advanced profiling for technical and composite materials

TECHNOLOGY AND AUTOMATION

At the heart of the SLS is the V-Perfect technology, an exclusive patent of Graf Synergy, which allows for perfect aesthetic welds without seams and eliminates the need for cleaning. The CNC system ensures stability, repeatability, and precision in every cycle.

- Automatic profile calibration

- 100% Automated Cycle

- Compatible with Industry 4.0 (upon request)

- Integrated electronic control

Contact us to find out if the SLS is the right solution for your production.