SL8 FF TR

8-Head CNC Welder for Seamless PVC Windows

The world’s first 8-head welding machine that combines production power with a perfect finish.

Perfect if you want:

- Automating the complete welding of frames with 2 cross members.

- Remove any cleaning or touch-up operations on the corners.

- Working with coated profiles using all types of films, acrylic, wood, or aluminium.

- Automatically compensate for the dimensional tolerances of profiles.

- Reduce production times and operational staff.

Request the technical brochure now or speak with an expert.

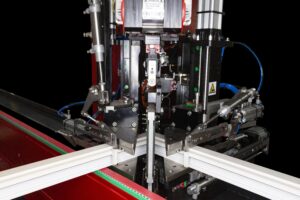

Perfect horizontal welding without a bead, even on complex profiles.

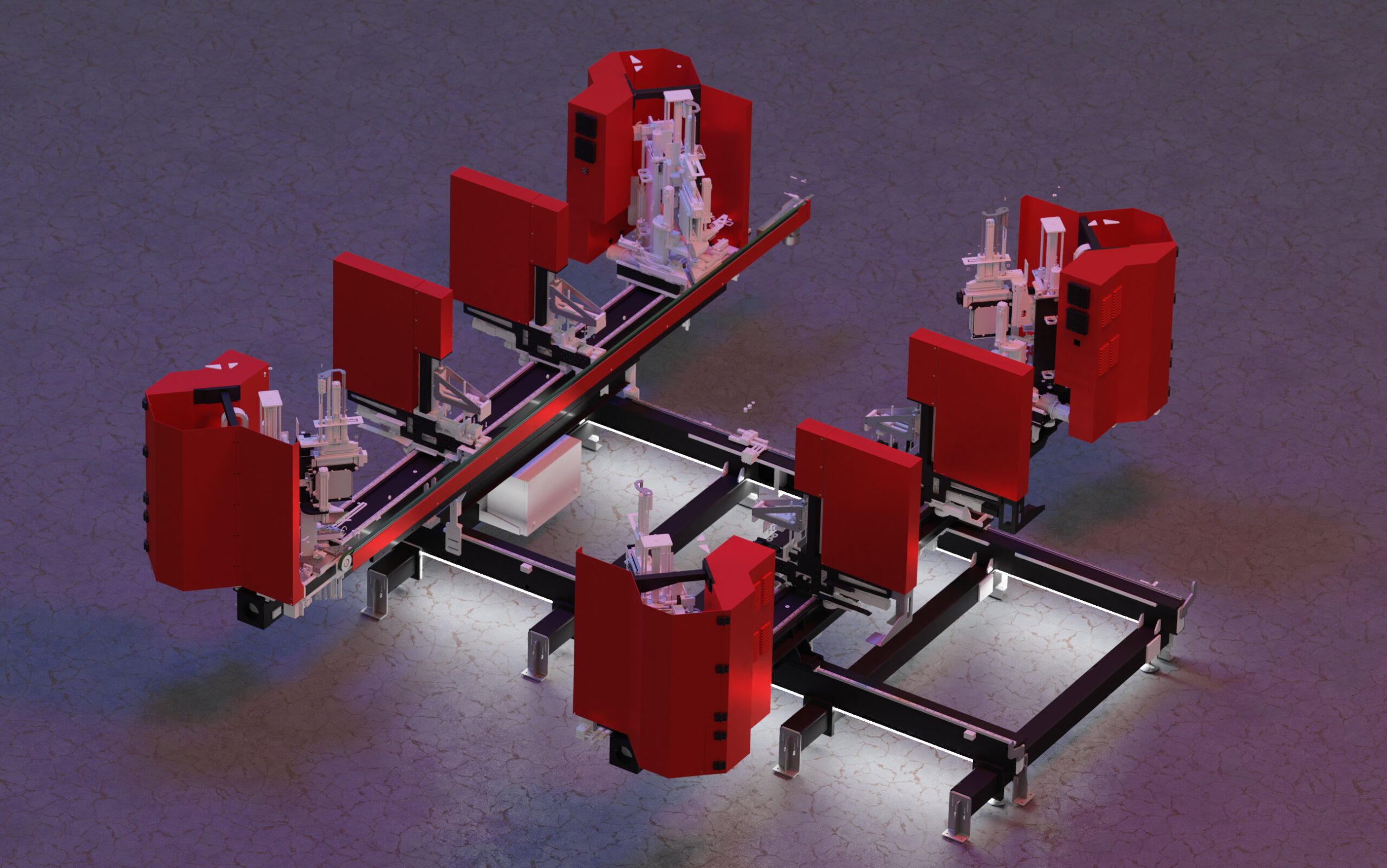

The SL8 FF TR is the world’s first CNC welder with 8 heads capable of performing simultaneous welding of the 4 corners at 45° and the 2 cross members at 90° in a single cycle, completely eliminating the weld seam.

The result? PVC frames with an impeccable aesthetic finish, perfectly flat and uniform, even on profiles with non-weldable inserts such as fiberglass, aluminium, or resin.

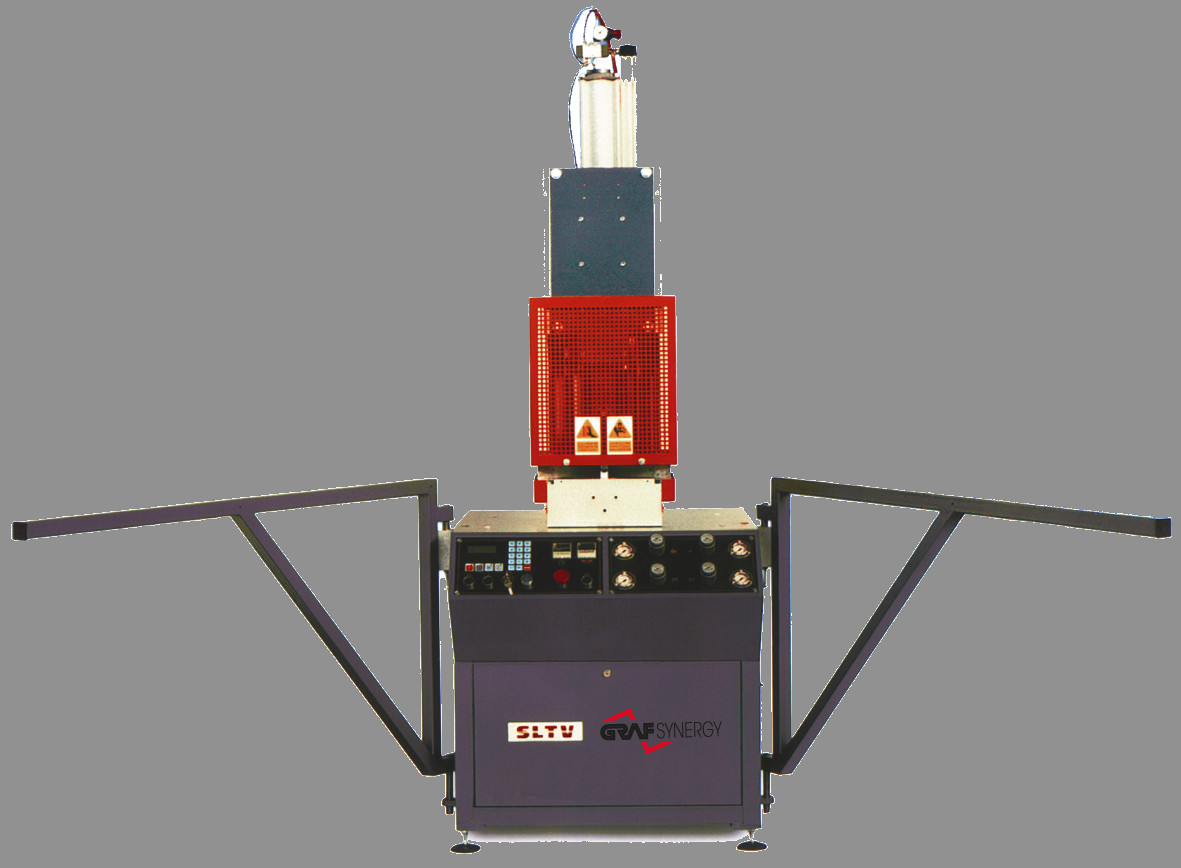

The automated evolution of the SL4 FF EVO, the SL8 FF TR incorporates the patented V-Perfect technology, allowing for a drastic reduction in cycle times, labour, and footprint. It is ideal for high-productivity companies looking to eliminate any post-welding rework and automate the entire process.

5 reasons to choose SL8 FF TR

- One cycle for the complete frame. Simultaneous welding of the 4 corners and the 2 cross members at 90° in less than 140 seconds with just one operator.

- No rework. The Patented Seamless Welding technology eliminates the need for seams: no cleaners, touch-ups, or rotating tables are required.

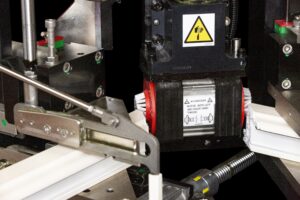

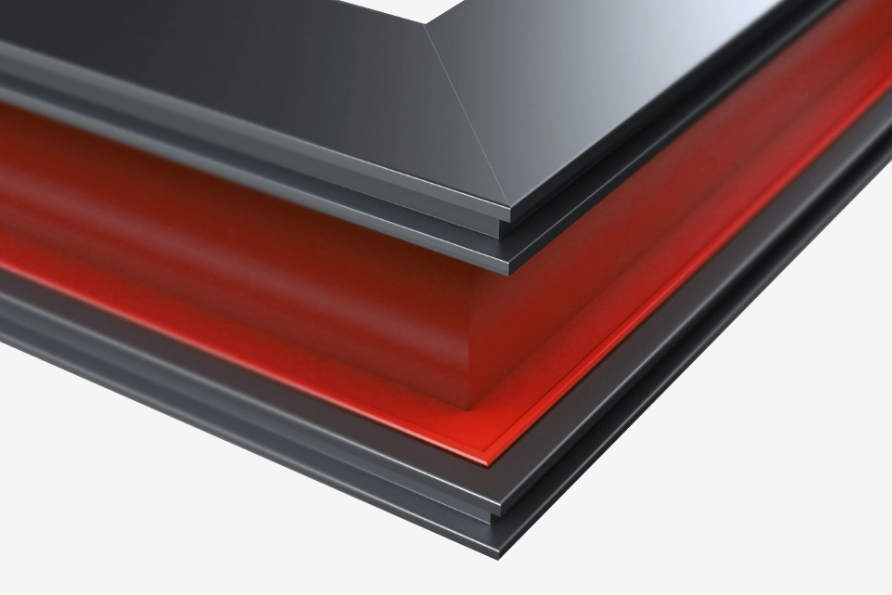

- Compatible with all coatings. Painted PVC, acrylic films, wood or aluminium laminates: a perfect finish on every surface.

- Automatic Tolerance Compensation. An intelligent system automatically corrects variations in cutting, geometry, and profile height.

- Maximum automation, minimal labour. The entire process is managed by CNC and proprietary software: you upload the profile, and the machine takes care of the rest.

Product Details

SL8 FF TR automates the entire welding process for complete PVC frames, ensuring simultaneous operations and perfect flatness of joints even on complex profiles.

Dimensions

Length: 7,000 ÷ 9,500 mm

Width: 6,000 to 7,000 mm

Height: 2,200 mm

Weight: 5,500 ÷ 8,000 Kg (depending on the configuration and frame size)

Performance

Cycle time: up to 1 frame every 140 seconds*

Operators required: 1

* Depends on the type of profile, seal, and curb

power supply and Consumption

Installed power: 22 kW

Power supply voltage: 400 V

Air consumption: 800 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Weldable dimensions: min. 350 x 435 mm | max. 4,000 x 6,000 mm (up to 6,000 mm on request)

Frame: Height 35 to 180 mm | Width 40 to 130 mm

Crossbar: Height 60 to 100 mm | Width 50 to 120 mm

Supported features and processes

- Horizontal welding of the 4 corners at 45°

- Front welding of the 2 cross members at 90°

- C Welds

- Welding thresholds (optional)

- Integrated gasket processing within the cycle

All stages are automated: High Speed milling, positioning, melting, compression, and cooling.

Optional features and custom configurations

The SL8 FF TR is configurable to meet the specific needs of each system:

- Enhanced cooling table (3628, 4028, 4528, 5028)

- RS Option – Rapid Speed for accelerated cycles

- TAG Mode for remote control and tracking of templates

Processing of ‘dormant large’ profiles (French standard)

Technology and automation

Each stage is managed by CNC with proprietary software, ensuring precise, traceable, and repeatable processes. The High Speed system guarantees efficient milling, while the Industry 4.0 logic enables:

- Remote Monitoring

- Predictive diagnostics

- Automatic data backup

With the integration of the TAG Application, you have full control over production and minimise machine downtime.

Download the full brochure or request a personalised consultation: our experts are ready to help you transform your production with SL8 FF TR.