SL6 FF TR

6-Head CNC Welder for Seamless PVC Profiles

The world’s first: perfect welding of 4 corners and 1 cross member in a single cycle, without a bead.

Perfect if…

- Do you want to completely eliminate post-welding cleaning?

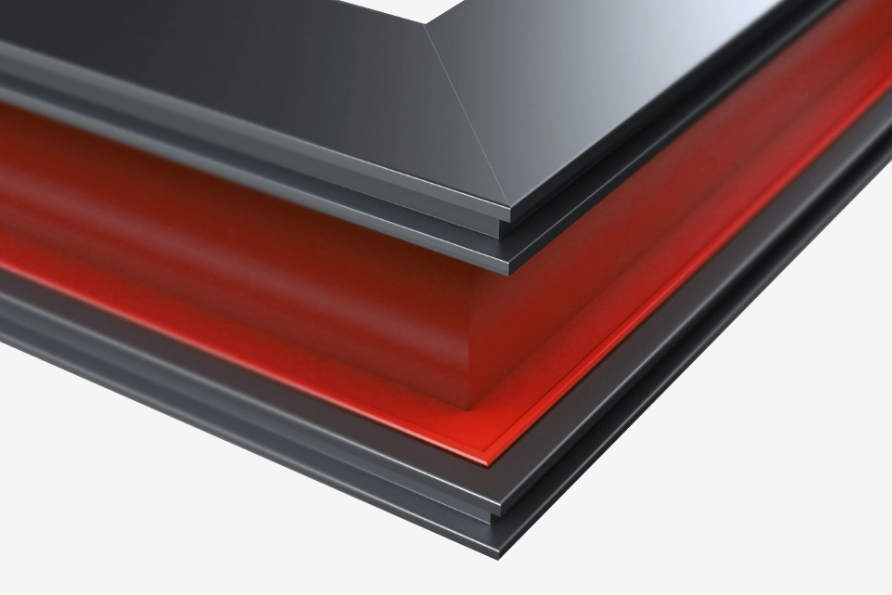

- We produce PVC frames with acrylic, wood, or aluminium coatings.

- You need to weld complete frames crosswise in a single cycle.

- Do you want to reduce staff on the line while maintaining efficiency?

- Are you looking for aesthetic quality even in profiles made of non-weldable materials?

Request the technical brochure now or speak with an expert

The world’s first: perfect welding of 4 corners and 1 cross member in a single cycle, without a bead

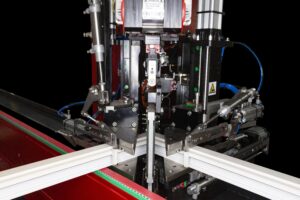

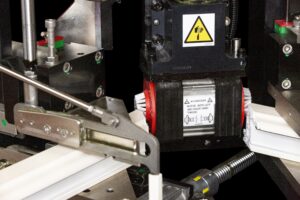

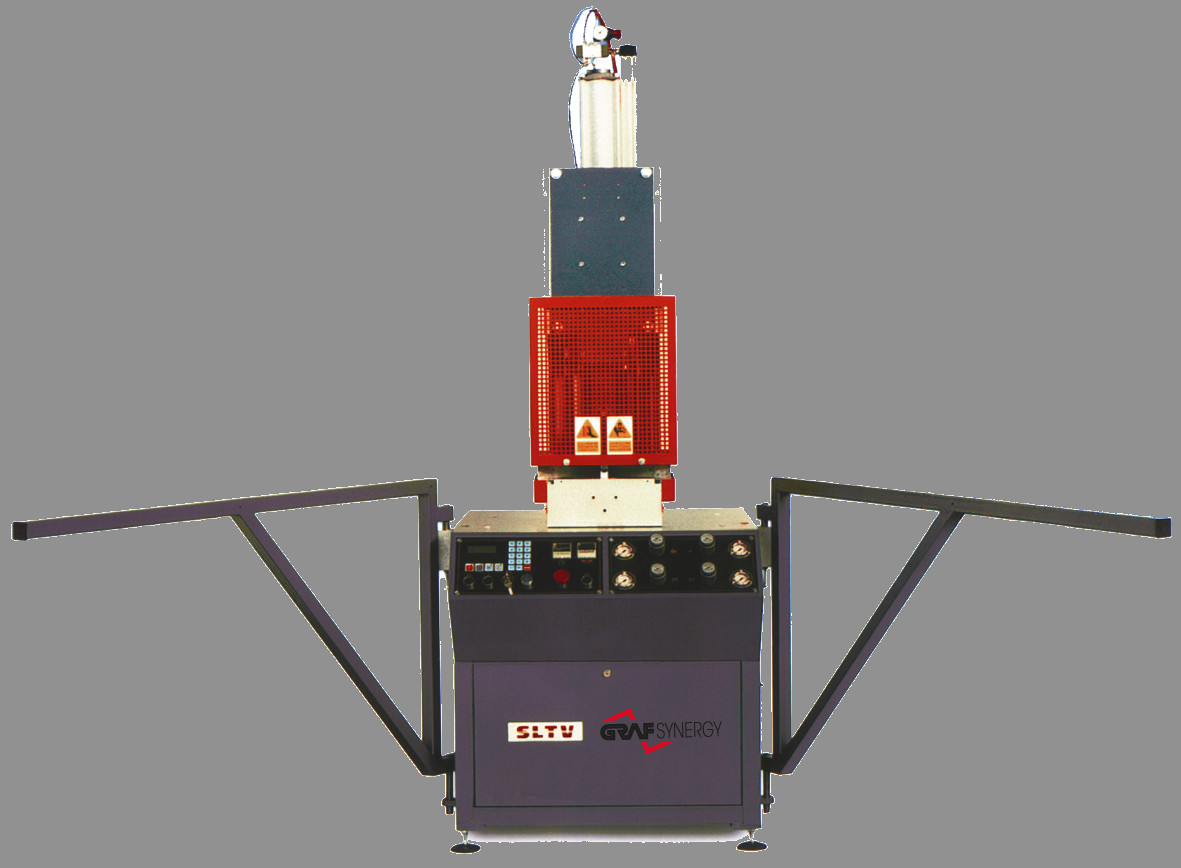

The SL6 FF TR is the first and only CNC welder with 6 heads capable of performing seamless front welds on PVC frames with a central crossbar, in a single cycle and without the need for reworking.

A direct evolution of the SL4 FF EVO, it incorporates the patented V-Perfect technology, completely eliminating the welding seam: the result is a window of superior aesthetic quality, featuring sharp, continuous, and uniform corners.

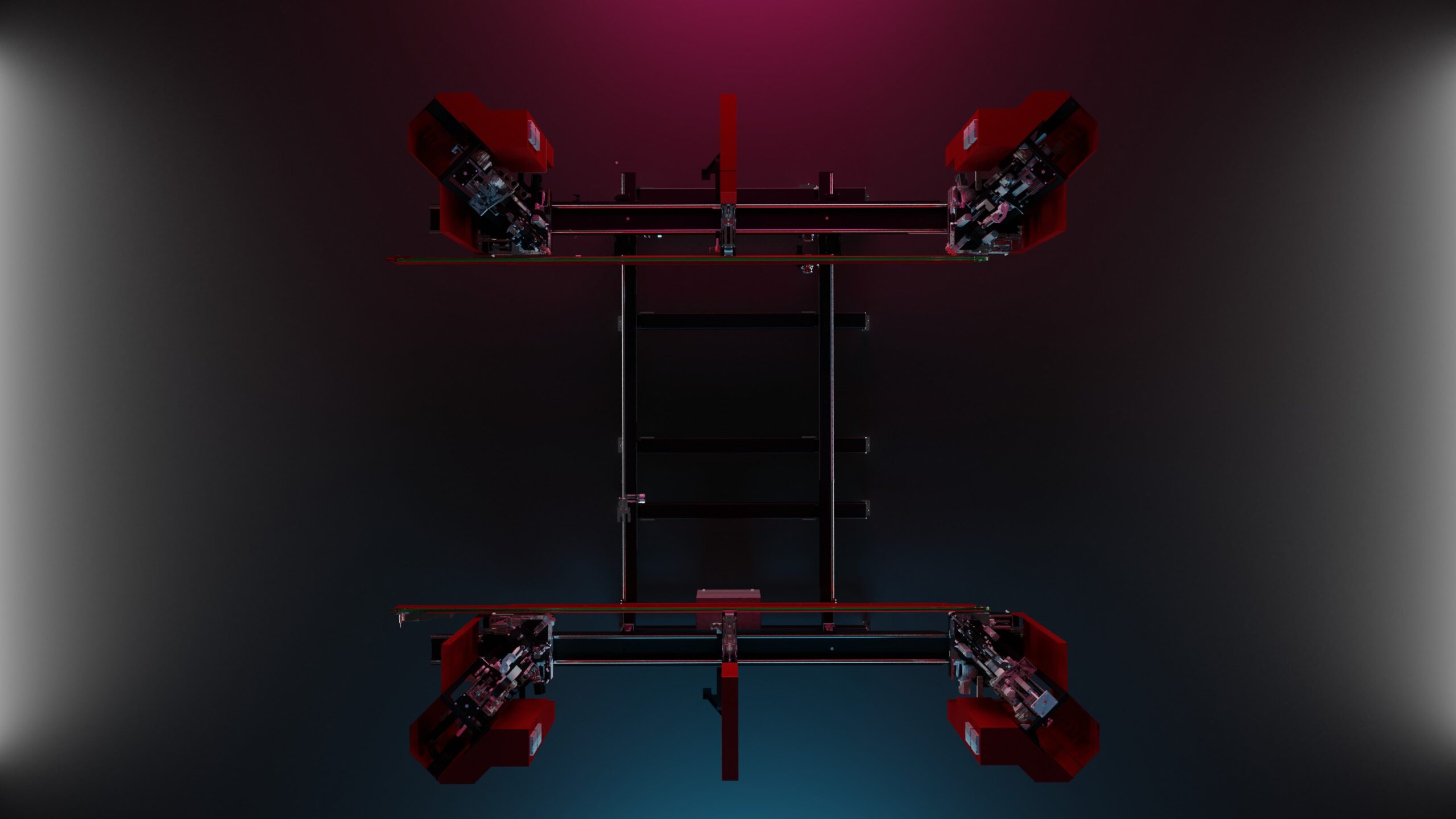

Thanks to the configuration with 6 square heads, it simultaneously welds the 4 corners at 45° and 1 cross member at 90°, resulting in significant savings in time and labour.

It is ideal for window and door manufacturers looking for maximum automation, impeccable quality on coated profiles, and inline integration in line with Industry 4.0.

5 reasons to choose SL6 FF TR

- Seamless aesthetics without reworking. Thanks to the V-Perfect patent, it eliminates the welding seam: no more cleaning or touch-ups required.

- A complete frame cycle. Simultaneous welding of the 4 corners and the crossbar at 90°, reducing manual steps and auxiliary devices.

- 1 single operator. All stages – milling, melting, compression, cooling – are fully automated.

- Every profile, every coating. PVC coated or painted, acrylic films, wood or aluminium laminates: perfect welding on every combination.

- Tolerances under control. Intelligent calibration system to compensate for differences in cutting angles and profile height.

Product Details

The SL6 FF TR fully automates seamless welding, even on profiles with non-weldable inserts (fibreglass, aluminium, resin).

Dimensions

Length: 7,000 ÷ 9,500 mm

Width: 6,000 to 7,000 mm

Height: 2,200 mm

Weight: 5,500 to 8,000 kg (depending on the requested configuration)

Performance

Cycle time: up to 1 frame every 140 seconds*

Operators required: 1

* Varies based on profiles, seals, and configuration

power supply and consumption

Installed power: 20 kW

Power supply voltage: 400 V

Air consumption per cycle: 800 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Maximum weldable size: 4,000 x 6,000 mm

Minimum weldable size: 350 x 435 mm

Leaf/frame height: 35 ÷ 180 mm

Width of door/frame: 40 ÷ 130 mm

Height of crossbars: 60 to 100 mm

Cross member width: 50 to 120 mm

Supported features and processes

Thanks to the 6-head configuration, it achieves:

- Simultaneous welding of the 4 corners + 1 crossbar

- C Welding

- Welding thresholds

- Integrated gasket processing within the cycle

Each stage is carried out automatically: milling with a High Speed system, operational positioning, melting, compression, cooling, and release of the frame.

Optional features and custom configurations

The SL6 FF TR is available in various configurations to meet every production need:

- Enhanced cooling table (sizes 3628, 4028, 4528, 5028)

- Additional heads for double welding of cross members

- RS Option – Rapid Speed

- Processing of ‘dormant large’ profiles for the French market

TAG System for Contour Moulds for Remote Monitoring and Management

Technology and automation

Equipped with advanced CNC controls and state-of-the-art sensors, the SL6 FF TR ensures precise, repeatable, and traceable welds. It is designed for integration in Industry 4.0 environments and is compatible with digital factory management systems.

The TAG Application module enables continuous monitoring of parameters, remote diagnostics, cloud backup, and predictive management to reduce machine downtime.

Want to see the SL6 FF TR in action? Book a personalised demo or request the full brochure: the Graf Synergy team is ready to show you how to take your production to the next level.