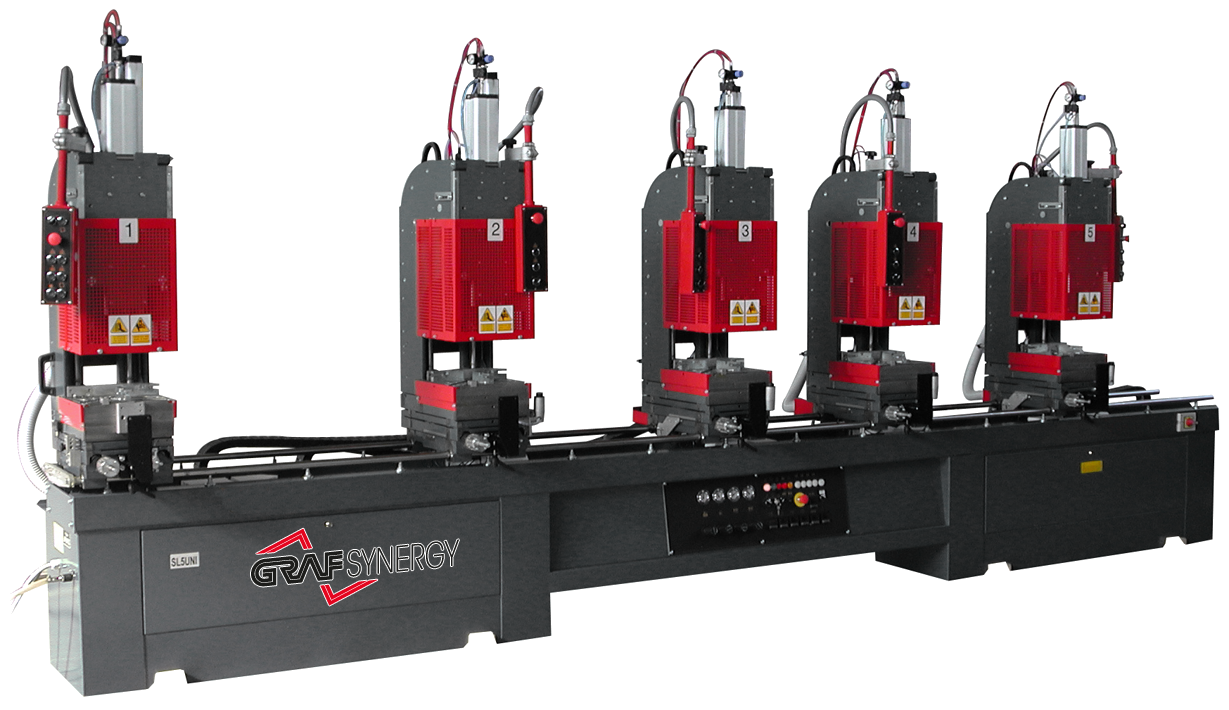

SL5 UNI

Universal 5-Head CNC Welder for Variable Angles and Multiple Joints

Maximum flexibility: one machine for all window frame welding configurations

Perfect if:

- Produce complex frames with multiple welded cross members simultaneously.

- You need variable configurations (angles, crosses, “T”, “H”) with a single machine.

- Do you want to reduce cycle times with a combined multi-welding process?

- Are you looking for a modular and reconfigurable welder depending on the job?

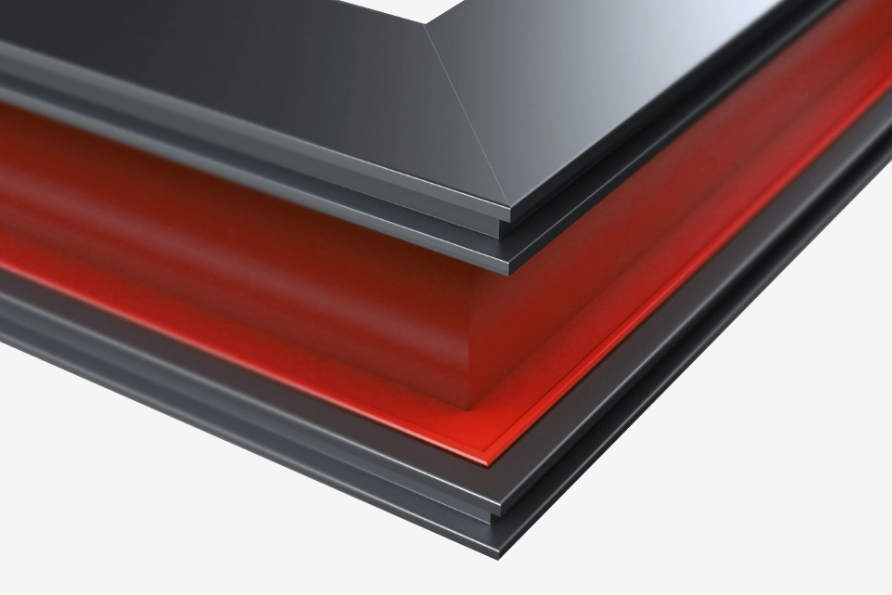

- You work with film-coated or painted profiles, including those with irregular tolerances.

- Do you want to automate the process without sacrificing operational flexibility?

Request the technical brochure now or speak with an expert.

Maximum flexibility: a single machine for all window frame welding configurations

The SL5 UNI is an extremely versatile 5-head CNC welding machine, designed for complex operations and special configurations. It can simultaneously weld 90° angles, T-joints, cross joints, or H-joints, as well as variable angles between 35° and 180°. A dedicated selector allows it to be used as two distinct machines: a dual-head and an independent triple-head, optimising combined cycles. The cycle is fully automated, and the management technology ensures precision, stability, and repeatable quality on every type of profile.

5 reasons to choose the SL5 UNI Horizontal Sliding Table

- One machine, endless possibilities. Simultaneous welding of corners, crosspieces, and various joints in every possible combination.

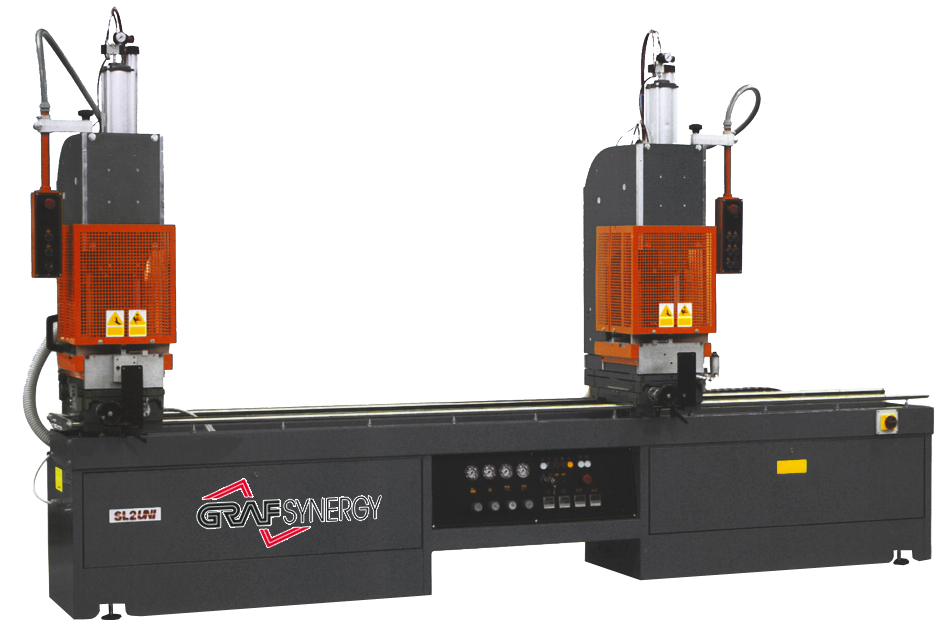

- Select between dual/triple head modes. It can operate as two distinct units: dual head + triple head, to enhance versatility and reduce time.

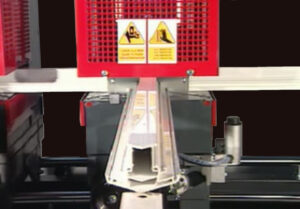

- Precision on every type of profile. Advanced electronic system for temperature and cycle control, knife adjustment from 0.2 to 2 mm.

- Quick Change of Counter Templates. Intelligent mechanical system with quick attachment/detachment to speed up setup and reduce machine downtime.

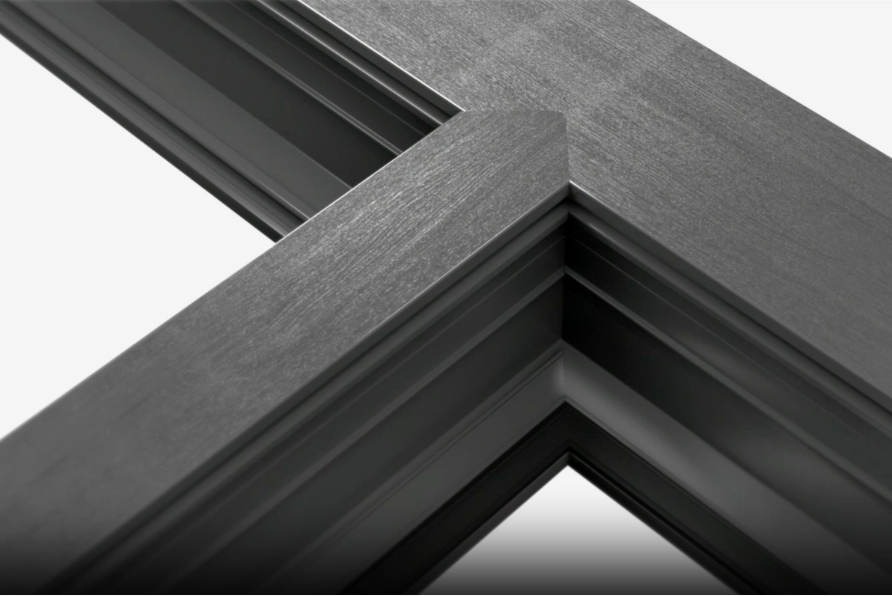

- Suitable for critical or coated profiles. Supports large or decorative profiles, always ensuring aesthetically pleasing and dimensionally accurate welds.

Product Details

The SL5 UNI allows for the simultaneous welding of multiple points on the frame in a single phase. It is perfect for those who create custom windows, complex fixtures, or bespoke orders with high aesthetic and structural demands.

Dimensions

Length: 5,700 mm

Width: 900 mm

Height: 2,350 mm

Weight: 2.100 Kg

Performance

Combined multiple welds in 2 cycles for a complete window

Manual operating mode with automated cycle

Strongly required operators: 1

power supply and consumption

Installed power: 14 kW

Voltage: 400 V

Air consumption per cycle: 225 NI/min

Operating pressure: 7 bar

Weldable profiles

Profile height: 40 to 200 mm

Profile width (at 90°): 40 ÷ 130 mm

Supported features and processes

- 90° angles and variable angles (35°-180°)

- T-junctions, Cross junctions, and H-junctions

- Simultaneous double-ended crossbar

- Sequential combined welds

- Processing of decorated and laminated profiles

Optional settings and configurations

To enhance its operational capabilities, the SL5 UNI can be equipped with:

- Automatic crossbar adjustment

- Additional support arms for each head

- Custom counter-sunk designs (left/right, horizontal/vertical)

Technology and Automation

Equipped with an advanced electronic control system, the SL5 UNI manages the entire process: from the control of the welding plates to the adjustment of the limit knives, adapting to every type of profile or material.

- Integrated Electronic Management of Cycle and Temperatures

- Adjustable edging knives from 0.2 to 2 mm

- Quick template replacement system

- Fully automated cycle

- Industry 4.0 Compatibility (upon request)

Contact us to find out if the SL5 UNI is the right solution for your production.