SL4FF WD

CNC 4-Head Welder for Wood Effect Profiles and Seamless Welding

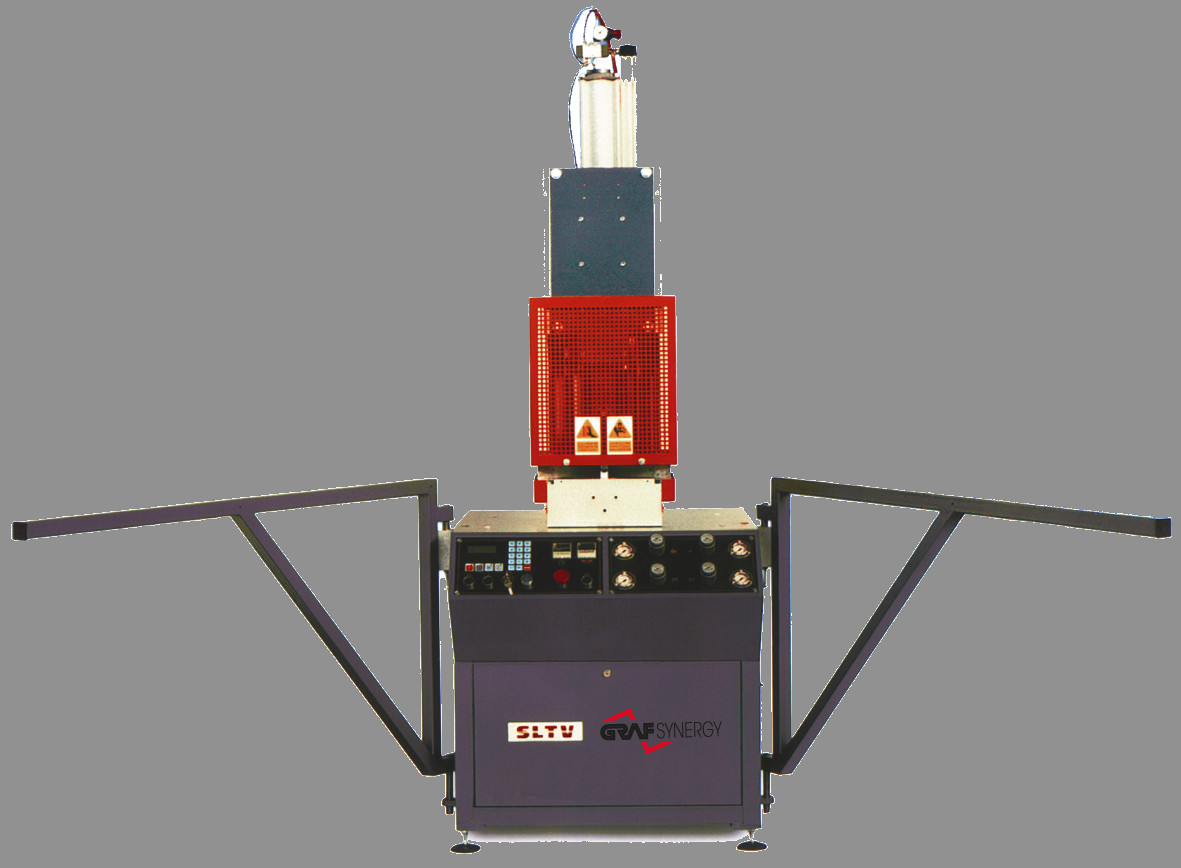

The world’s first welder that combines a wood-effect aesthetic with seamless performance.

Perfect if:

- Remove the welding bead from the corners of the fixtures.

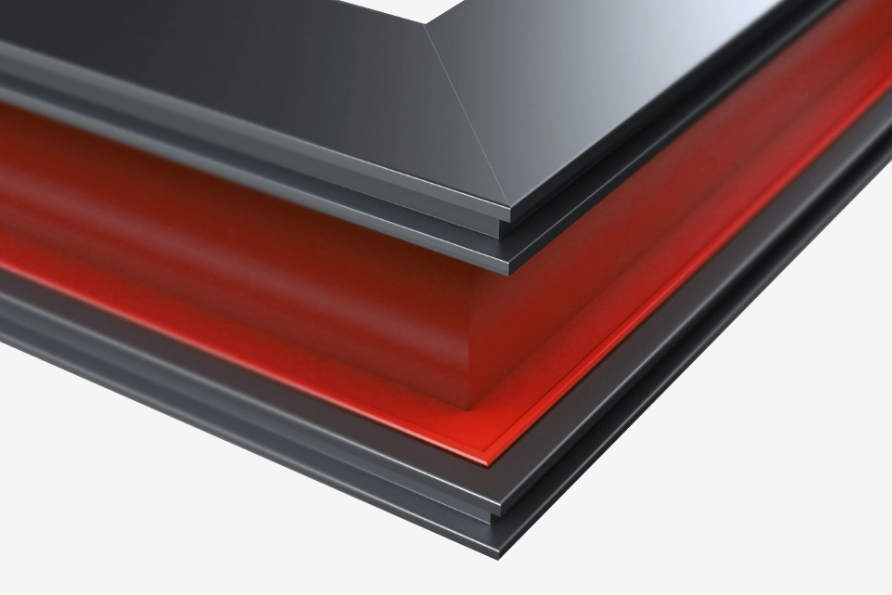

- Faithfully reproduce the wood effect with a 45°/90° joint.

- Working on profiles with fiberglass, aluminium, or resin inserts.

- Reduce production time and labour costs.

- Achieve flawless finishes without the need for cleaning or touch-ups.

- Integrating the welder into an Industry 4.0 line

Request the technical brochure now or speak to an expert.

The world’s first welder that combines a wood-effect aesthetic with seamless performance.

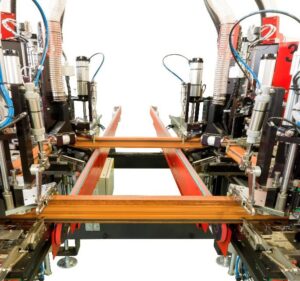

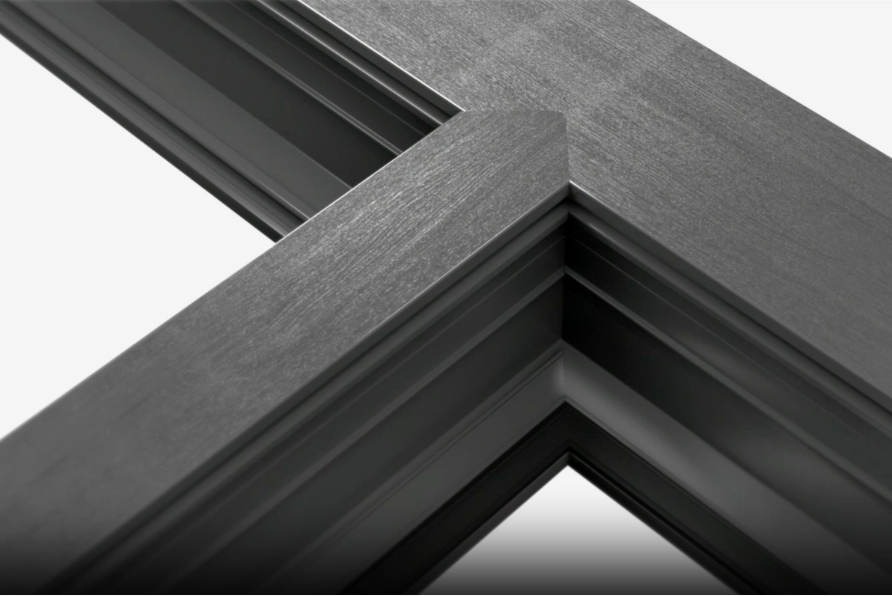

SL4FF WD is the first CNC welder with 4 heads capable of completely eliminating the weld seam from corners, producing PVC frames with superior aesthetic quality, even on complex profiles such as wood-effect designs. This revolutionary technology allows welding on two sides with different geometries (45° + 90°) to faithfully replicate the appearance of wooden frames, without compromising on strength and precision.

Thanks to the patented V-Perfect technology, the machine processes coated, painted, and laminated profiles made of wood or aluminium without the need for post-processing touch-ups. All operations – milling, positioning, fusion, compression, and cooling – are fully automated and ensure consistent results even on profiles with non-weldable internal materials.

5 Reasons to Choose SL4FF WD

- Unique wood effect welding. Achieve the ‘timber look’ with the double 45° and 90° joint geometry on opposite faces.

- Seamless welds without reworking. Eliminate the bead with V-Perfect technology: smooth surfaces, no manual cleaning required.

- Maximum compatibility with special materials. Works with profiles that have non-weldable cores such as fibre, aluminium, and resin.

- Active Control of the Final Result. Active welding system with software adjustments for customised results.

- One operator, maximum efficiency. No need for a cleaner or a rotating table: optimising time and resources.

Product Details

SL4FF WD is the first CNC welder with 4 heads capable of completely eliminating the weld seam from corners, producing PVC frames with superior aesthetic quality, even on complex profiles such as wood-effect designs. This revolutionary technology allows for welding on two sides with different geometries (45° + 90°) to faithfully reproduce the appearance of wooden windows, without compromising on strength and precision.

Sizes

Length: 7,000 – 10,000 mm

Width: 7,000 mm

Height: 2,200 mm

Weight: 5,500 – 8,000 kg (depending on the configuration)

Performance

Installed power: 90-150 seconds per complete frame (variable)

Productivity: up to 1 frame per cycle

Operators required: 1

Power supply

Installed power: 28 kW

Voltage: 400 V

Air consumption per cycle: 600 NI/min

Operating pressure: 7 bar

Workable profiles

Weldable profile:

- Height: 35 ÷ 180 mm

- Width: 40 ÷ 130 mm

- Weldable dimensions: min. 420 x 370 mm (wood) / max. 3,500 x 6,000 mm

Supported features and processes

SL4FF WD performs simultaneous horizontal welding of the four corners of the frame, with integrated sealing in the cycle. The CNC system ensures absolute precision in operational dimensions and in the thermal management of melting and compression.

Main processes:

- Seamless welding on 4 corners

- Timber look welding with one side at 45° and the other at 90°

- Automatic milling pre-welding

- Integrated gasket management

Special modes:

- C Welding

- Welding of three sides for U-shaped door frame

Optional and configurations

To meet every production requirement, the SL4FF WD is available with a wide range of options:

- Electronic control of counter-profiles

- Integrated chip vacuum

- Automatic cooling table

- Mobile discharge belts with lateral movement

- Imported file conversion software

- Production data monitoring with advanced traceability

TECHNOLOGY AND AUTOMATION

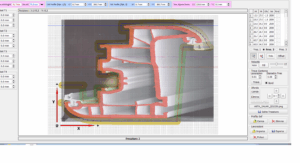

SL4FF WD integrates V-Perfect technology and an advanced CNC system to ensure complete digital control. The operator can define detailed milling parameters, moulds, and casting cycles directly from the software, anticipating the final outcome.

The machine is designed for integration into Industry 4.0 ecosystems, featuring:

- Remote monitoring and control

- Compatibility with business management systems

- Automatic backup of parameters via TAG Application

Contact us to find out if the SL4FF WD is the right solution for your production.