SL4FF EVO RS

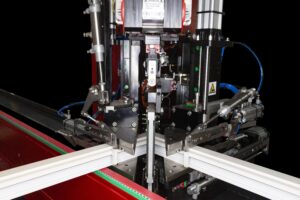

4-Head CNC Welder with V-Perfect Technology

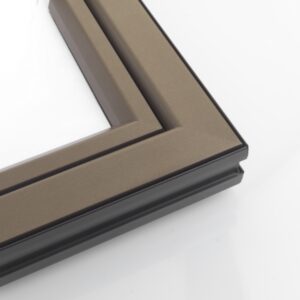

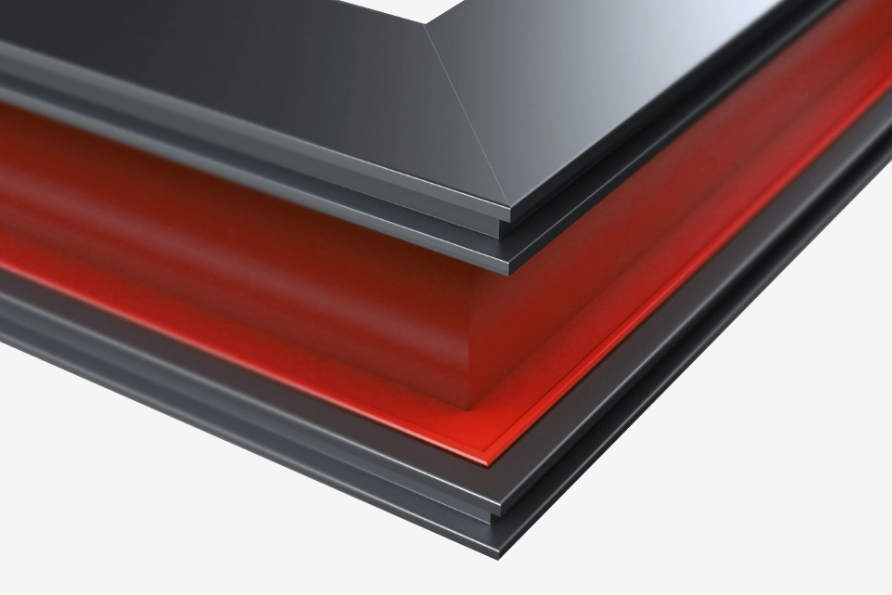

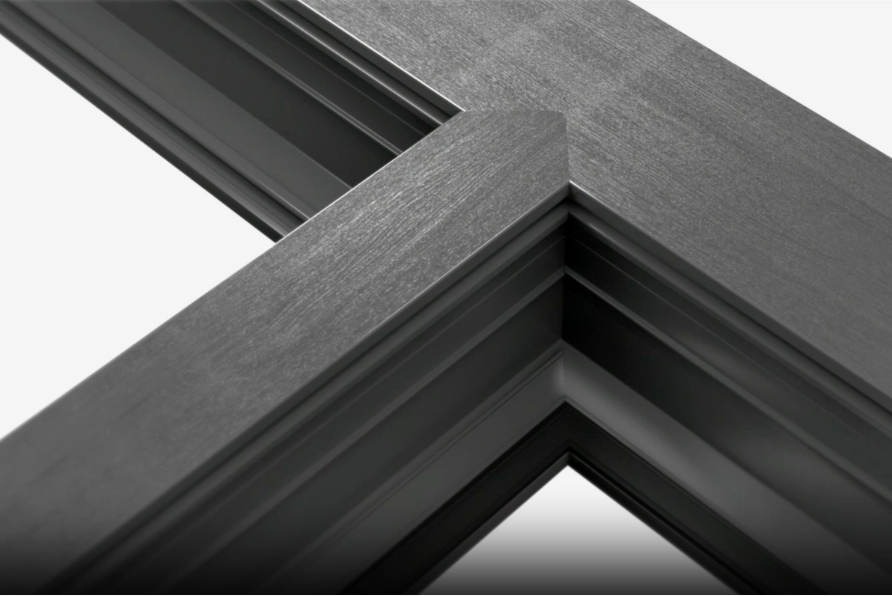

The aesthetic revolution in PVC welding

Perfect if:

- Create PVC windows with a perfect aesthetic finish, even on coated profiles or mixed materials.

- Completely remove the weld bead from the corners.

- Increase productivity with reduced cycle times

- Working with a single operator

- Reduce the occupied space and finishing costs.

Request the technical brochure now or speak with an expert.

The aesthetic revolution in PVC welding

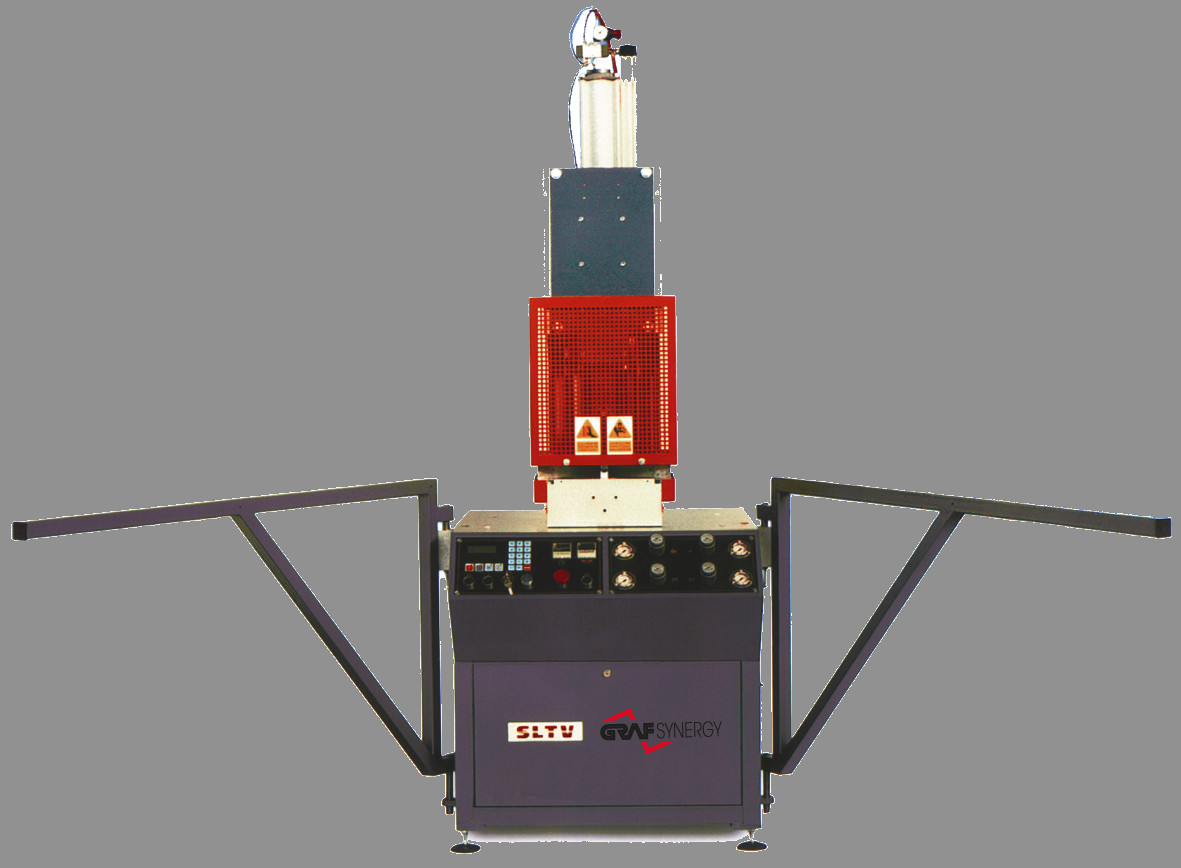

The SL4FF EVO RS is the world’s first and only CNC welder with 4 heads capable of completely eliminating the bead from the corner, achieving a perfect, flat, and uniform weld even on difficult or unsolderable profiles.

Equipped with patented V-Perfect technology and an advanced axis control system, it ensures precision, speed, and superior aesthetic quality, without the need for cleaning or touch-ups. Everything is automatic, all in a single cycle.

5 Reasons to Choose SL4FF EVO RS

- Perfect on every material. Painted, foiled, acrylics, wood or aluminium laminates: it bonds everything without leaving a bead.

- Optimised cycle time. Up to 1 complete frame every 80-140 seconds* without subsequent processing.

- Minimal labour. Only 1 operator is needed: the welding process is fully automated.

- Compact structure. Reduced layout: starting from just 25 m², even for special configurations.

- Automatic Tolerance Compensation. Integrated system for correcting cutting errors of up to 2 mm and height misalignments of up to 0.5 mm. (*depending on the type of profiles and seals)

Product Details

The SL4FF EVO RS is the world’s first and only CNC welder with 4 heads, capable of completely eliminating the weld seam from the corner, achieving a perfect, flat, and uniform weld even on difficult or unsolderable profiles.

Machine dimensions

Length: 7,000 – 9,500 mm

Width: 6,000 – 7,000 mm

Height: 2,400 mm

Weight: 3,000 – 5,000 kg (depending on configuration)

Power supply

Installed power: 17 kW

Voltage: 400 V

Air consumption per cycle: 600 NI/min

Operating pressure: 7 bar

Operational Features

Composition: 4 Quad Heads. CNC

Welding type: horizontal, simultaneous at all four corners

Operators required: 1

Seal machined directly during the cycle

Working dimensions

Weldable side:

- Minimum: 300×330 mm

- Maximum: 3,200 mm (up to 6,000 mm upon request)

Weldable profile:

- Height: 35 – 130 mm

- Width: 40 – 130 mm

Optional settings and configurations available

- Additional heads for drilling or cross screwing

- Electronic Control of Counter Profiles

- Mobile discharge belts with lateral translation

- FF Series Welding Fume Extractor

- C or three-sided welding for U-shaped door frames

- Data conversion software for imported files

- Data production monitoring (timing, cycles, optimisations)

- Welding height up to 180 mm (upon request)

- Dedicated cooling table

- Special configurations for non-standard formats

- UL/CSA Version for International Markets

Technology and Automation

The SL4FF EVO RS integrates High Speed milling, automatic positioning, fusion, compression, cooling, and release in a single continuous cycle. The burn is adjustable (5-6 mm) and the positioning of the upper counter-mould is secured with magnetic locking.

The software automatically manages every parameter, while the CNC system corrects angular and dimensional errors in real-time. It is the ideal welding machine for high-quality production, with impeccable aesthetics and maximum efficiency.

Contact us to find out if the SL4FF EVO RS is the right solution for your production.