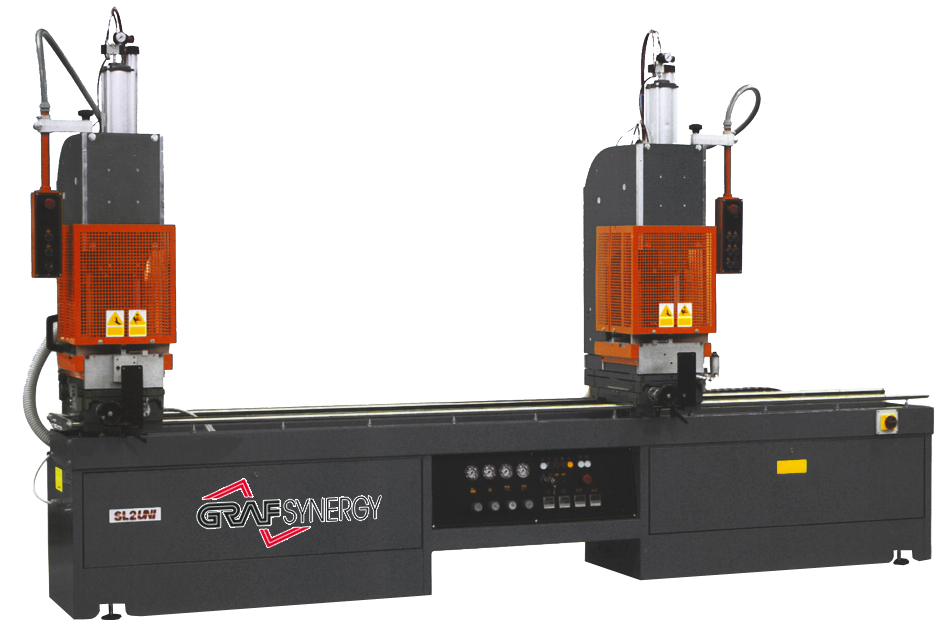

SL4 UNI

Universal 4-Head CNC Welder for Complex Angles and Crossbars

All geometries, one cycle, maximum productivity

Perfect if:

- Welding complete frames with cross members in a single cycle.

- Achieving maximum productivity for mixed batches and complex configurations.

- Integrate variable angle machining without changing machines.

- Working with just one operator

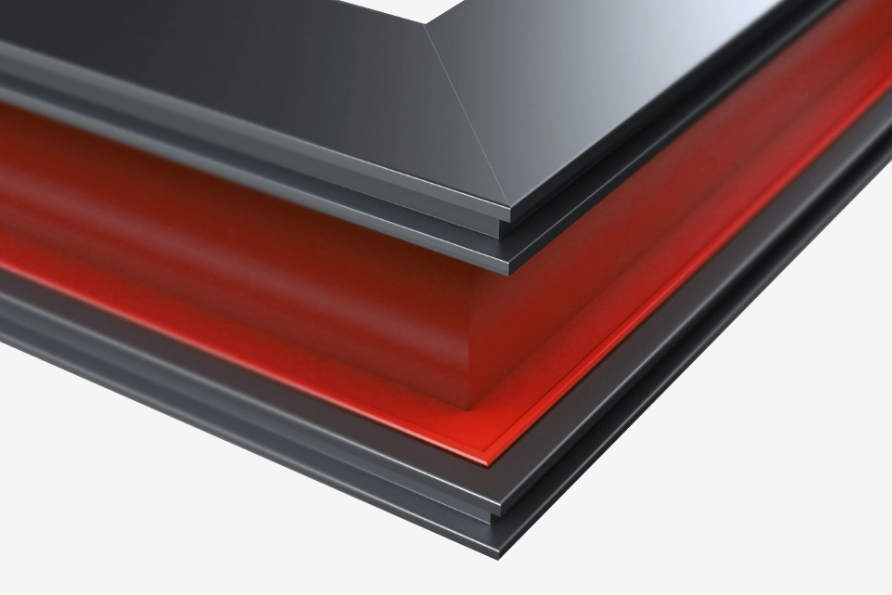

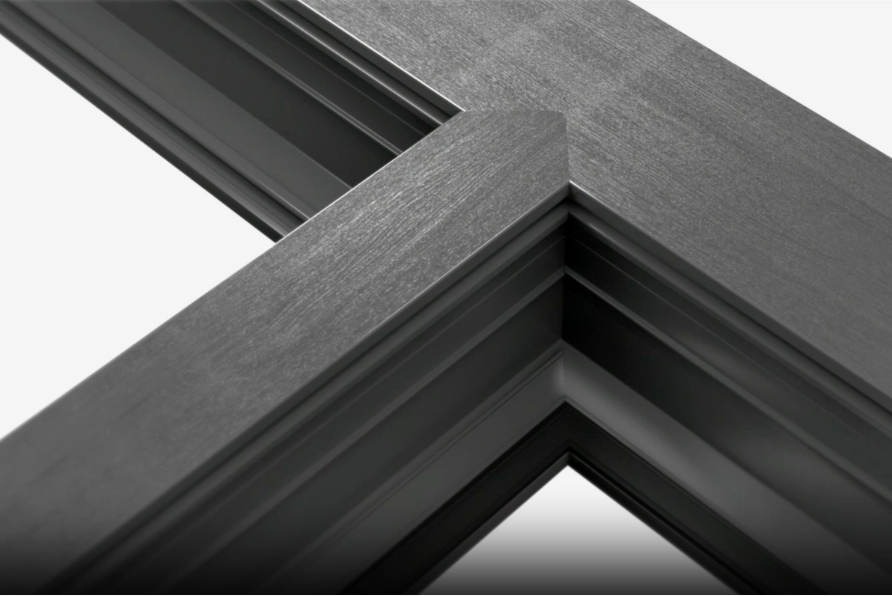

- Achieve a precise edge, adjustable between 0.2 and 2 mm, even on laminated surfaces.

Request the technical brochure now or speak with an expert.

All geometries, one cycle, maximum productivity

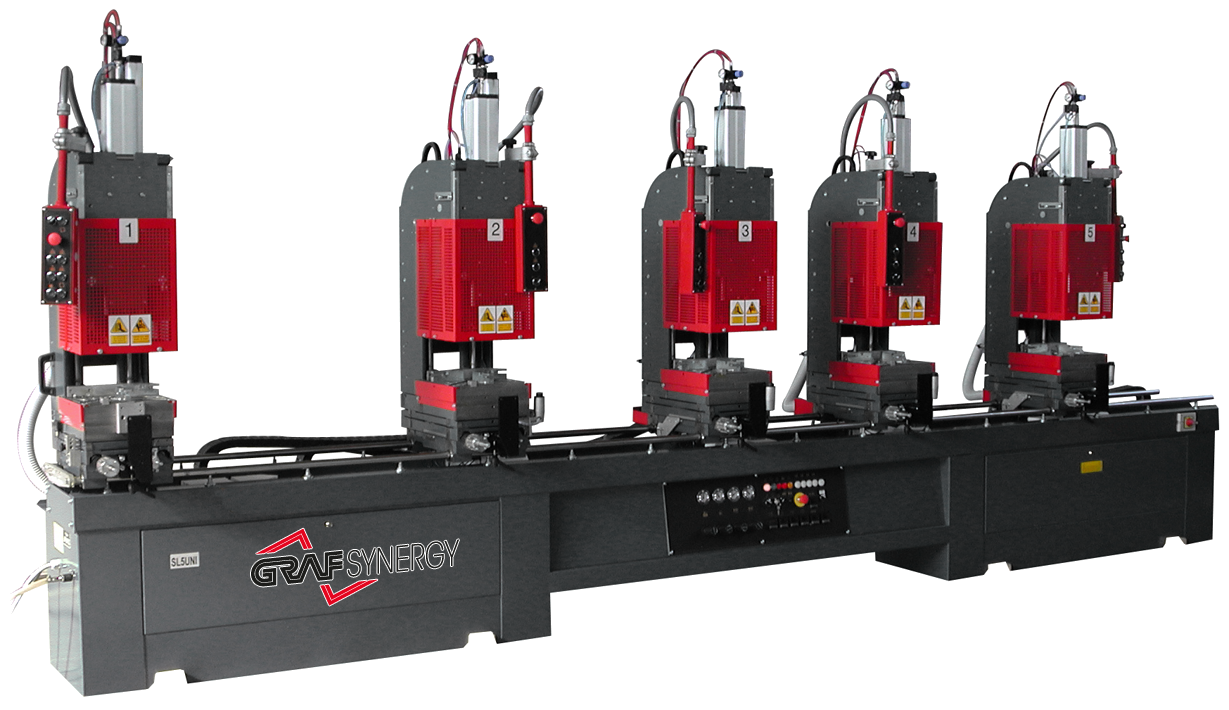

The SL4 UNI is the most comprehensive 4-head CNC welder in the Graf Synergy range. In a single work cycle, it allows for the simultaneous welding of 90° angles and internal cross members in ‘T’, cross, or ‘H’ configurations, even in combination. Additionally, two of the four heads can rotate 90°, enabling the simultaneous processing of both ends of a cross member.

The system is designed to ensure maximum flexibility with weldable angles ranging from 35° to 180°, electronic temperature control, and adjustable limit knives for perfect results on every material.

5 reasons to choose SL4 UNI

- A machine for every geometry. Welds at 90°, ‘T’, cross, ‘H’, and variable angles from 35° to 180° in any combination.

- Combined cycles for complete fixtures. In 2 cycles, you can create a complete window with two crosspieces, ready without any further processing.

- Dual Unit Mode. Usable as two independent dual-head welders to optimise time.

- Kerb always under control. Electronic system and adjustable blades for a perfect finish on whites, painted and wrapped surfaces.

- Quick Contour Change. Fast system for attaching/detaching contours for setup in seconds.

Product Details

SL4 UNI is the most comprehensive 4-head CNC welder in the Graf Synergy range. In a single work cycle, it allows for the simultaneous welding of 90° angles and internal cross members in T, Cross, or H shapes, even in combination. Additionally, two of the four heads can be rotated 90°, enabling the simultaneous processing of both ends of a cross member.

Machine dimensions

Length: 4,000 mm

Width: 900 mm

Height: 2,350 mm

Weight: 1.520 Kg

Power supply

Installed power: 13 kW

Voltage: 400 V

Air consumption per cycle: 180 NI/min

Operating pressure: 7 bar

Operational Features

Composition: 4 Inline Heads (2 rotatable at 90°)

Welding Types: 90° corners, T-joints, crosses, H-joints, variable angles from 35° to 180°.

Operating Modes: multiple and combined welds

Operators required: 1

Working dimensions

Weldable profile:

- Height: 40 – 200 mm

- Width: 40 – 130 mm (at 90°)

Optional features and available configurations

- Enhanced base for extra formats (total weight: 1.680 kg)

- Right head extension (L = 270 mm)

- Additional support for profile holder arm (1 per head)

- Custom-made counter jaws (Right/Left clamps, horizontal or vertical)

Technology and Automation

SL4 UNI is the benchmark for complex welding in custom productions. The system allows for the welding of mixed geometries and out-of-square angles with speed, precision, and a perfect finish.

The intuitive user interface, centralised CNC management, and quick tool change make it an ideal solution for companies that produce on demand or manage multiple configurations without compromising on quality and efficiency.

Contact us to find out if the SL4 UNI is the right solution for your production.