SL4-4

CNC 4-Head Welding Machine for PVC Profiles

Simultaneous welding of all four corners: consistent productivity, guaranteed precision.

Perfect if you want:

- Are you looking for a reliable CNC welder that can produce up to 240 panels per shift?

- We manufacture PVC profiles with stringent tolerances and precise aesthetic finishes.

- You need a compact car with a small footprint.

- Do you want to reduce tool change times and machine downtime?

- Are you looking for a solution that can be easily integrated with automatic cleaners?

Request the technical brochure now or speak with an expert.

Simultaneous welding of all four corners: consistent productivity, guaranteed precision.

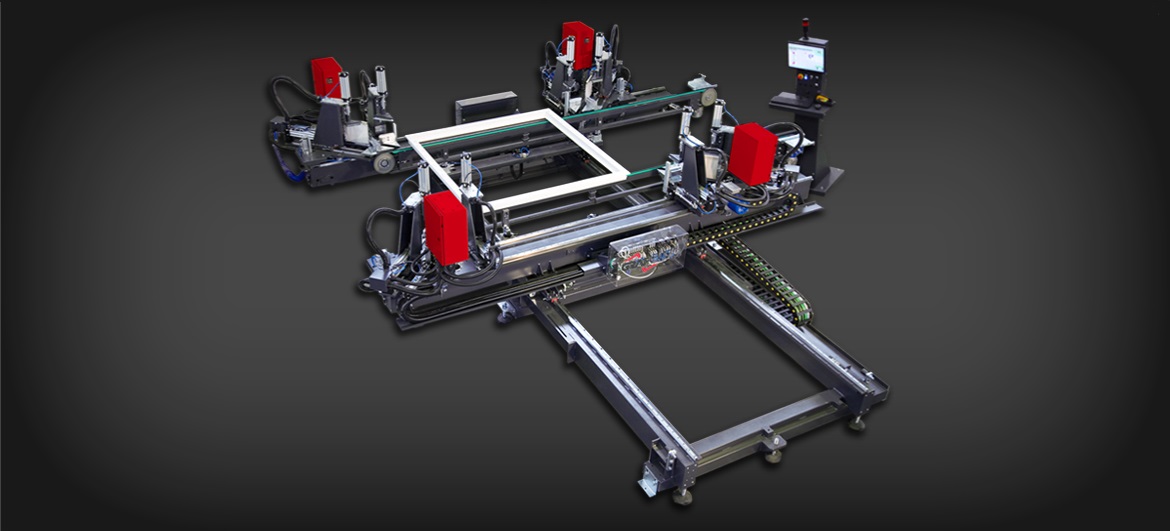

The SL4-4 is a CNC welding machine with four heads arranged in a square configuration, designed to fully automate the horizontal and simultaneous welding of the four corners of a PVC frame.

Thanks to the management on three controlled axes and its compact structure, it ensures smooth and repeatable operations over time, even at high production volumes.

From the positioning phase to welding, and finally to the release of the piece onto the conveyor belt towards the cleaning area, each step is optimised to minimise operator intervention and maximise overall efficiency.

5 reasons to choose SL4-4

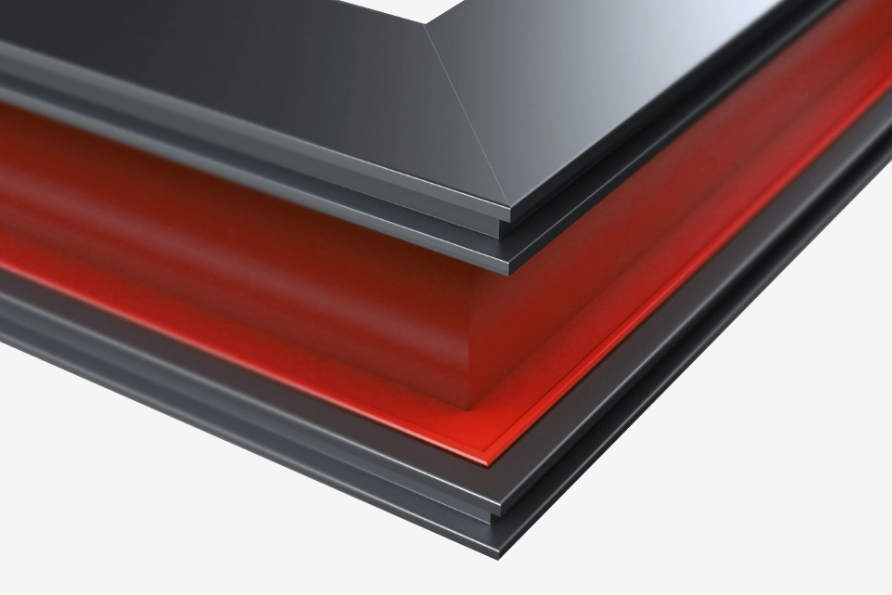

- Flawless welds. Perfectly flat and uniform surfaces, even with continuous cycles: consistent quality over time.

- Quick tool-free change. Quick attachment/detachment system for counter-moulds and non-stick fabric, zero downtime.

- Adjustable automatic burning. CNC management of burning (5÷6 mm) to accommodate different types of profiles.

- Ease of use and quick training. User-friendly interface with data acquisition via USB or TCP-IP network: ready to go immediately.

- Designed for integration. Can be directly connected inline with Graf Synergy cleaning machines to create a complete welding cell.

Product Details

The SL4-4 allows for the simultaneous welding of the four corners of a PVC frame in a horizontal position, with automatic management of the melting, compression, and cooling phases.

Machine dimensions

Length: 5,250 mm

Width: 2,200 mm

Height: 1,650 mm

Weight: 2,100 kg

Performance

Productivity: up to 240 frames / 8h*

Operators required: 1 (*depending on profiles, seals, and loading speed)

power supply and Consumption

Installed power: 12 kW

Voltage: 400 V

Minimum operating pressure: 7 bar

Air consumption: 180 Nl/min

Workable profiles

Profile height: 40 to 130 mm

Profile width: 40 to 130 mm

Minimum frame size: 400 x 400 mm

Maximum frame size: 3,200 x 2,800 mm

Supported features and processes

The precise movement of the heads is ensured by linear guides and high-precision racks, allowing for total control of the process even with tight tolerances. At the end of the cycle, the piece is automatically released onto exit belts.

Main processes:

- Simultaneous welding at four corners

- Fully automatic cycle.

Optional features and available configurations

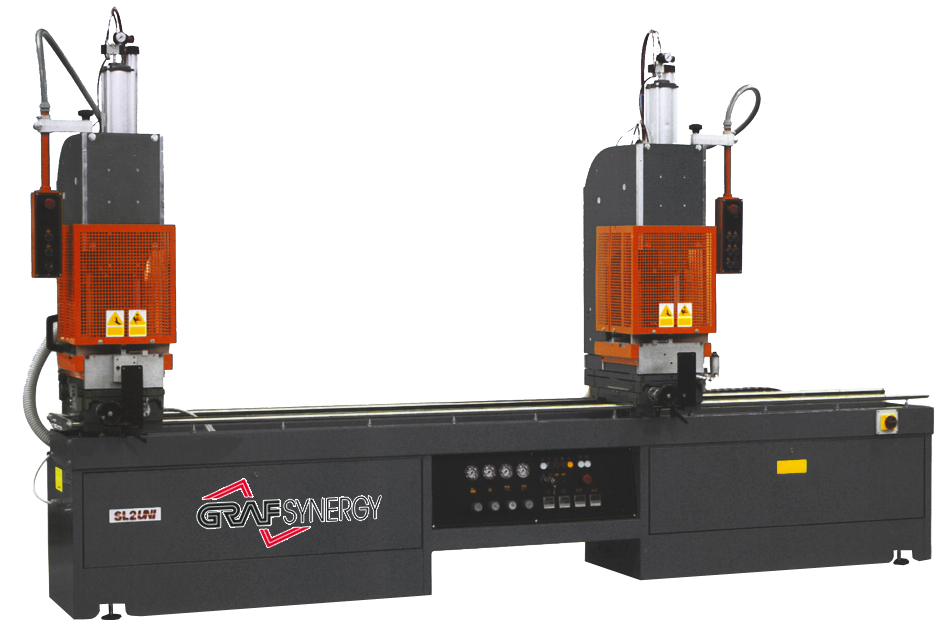

The SL2-2 can be customised with a range of options to enhance precision. To expand the functionalities of the SL4-4, it is possible to integrate:

- Cooling table to optimise the time between welding and cleaning.

- Online connection module for Graf Synergy automatic cleaners

These options make SL4-4 ideal for integration into automated and flexible work cells, adaptable to the most advanced production requirements.

Technology and automation

The SL4-4 stands out for its advanced automation of operations:

- Three-axis movement on CNC controls for maximum precision

- Digital measurement system for capturing data via USB or TCP-IP network.

- Optimised frame and canvas replacement system for quick format changes.

The machine can be easily integrated into Industry 4.0 production systems thanks to its connectivity and data communication capabilities, thereby providing traceability and optimising workflows.

Request a demo or quote

Find out how SL4-4 can enhance your window frame production line: contact the Graf Synergy team now for a personalised consultation, to request the technical brochure, or to book a demonstration of the machine in operation.