SL3 FF TV

Universal 5-Head CNC Welder for Variable Angles and Multiple Joints

One single cycle for a perfect fitting, including the crossbar.

Perfect if:

- Welding internal cross members with a ‘V’ aesthetic in a single cycle.

- Reduce labour, processing times, and the use of rotating tables.

- Eliminate post-welding touch-ups and clean-ups.

- Ensure accuracy and finish on every material or coating.

- Work with just one operator thanks to advanced automation.

Request the technical brochure now or speak with an expert.

A single cycle for a perfect fitting, including the crossbar.

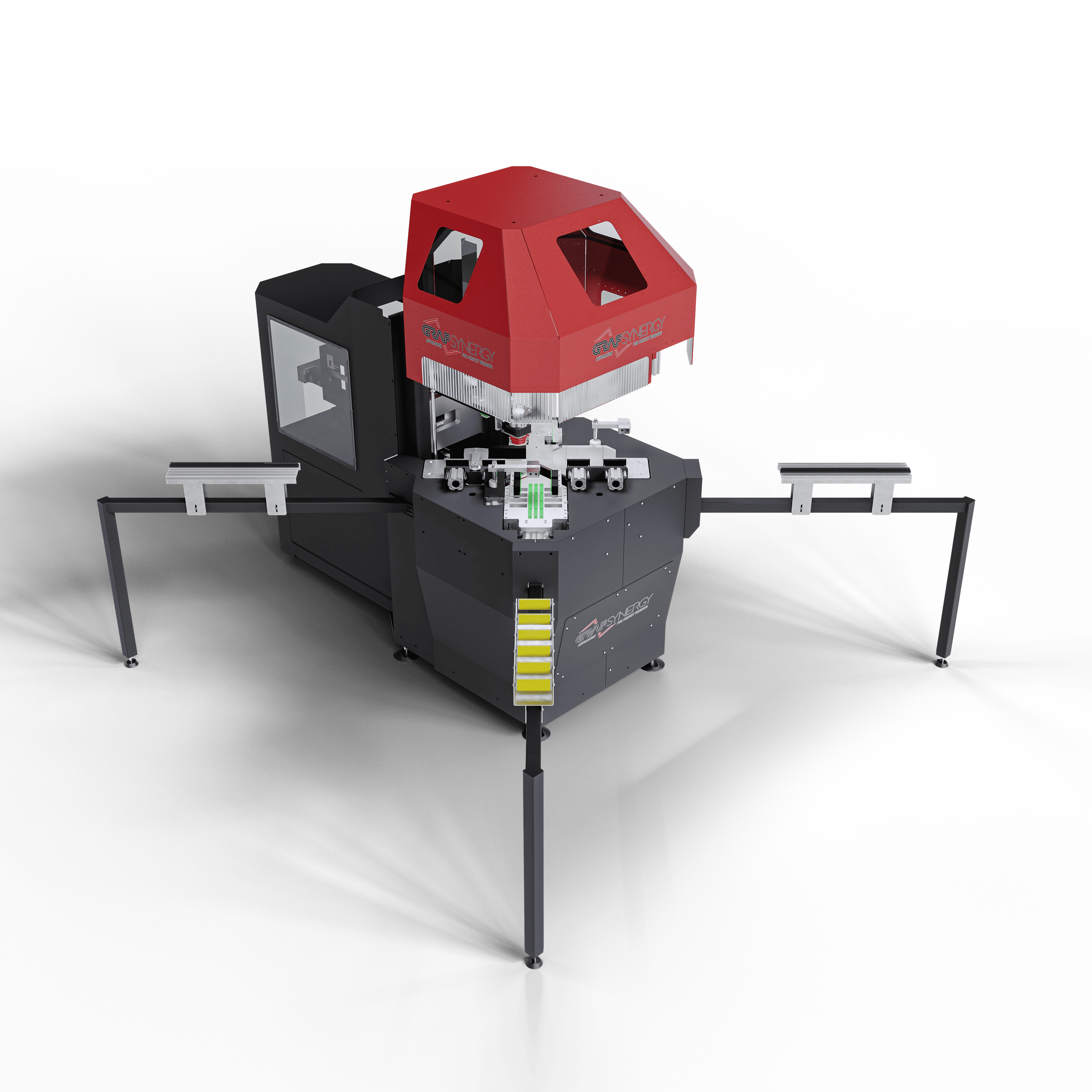

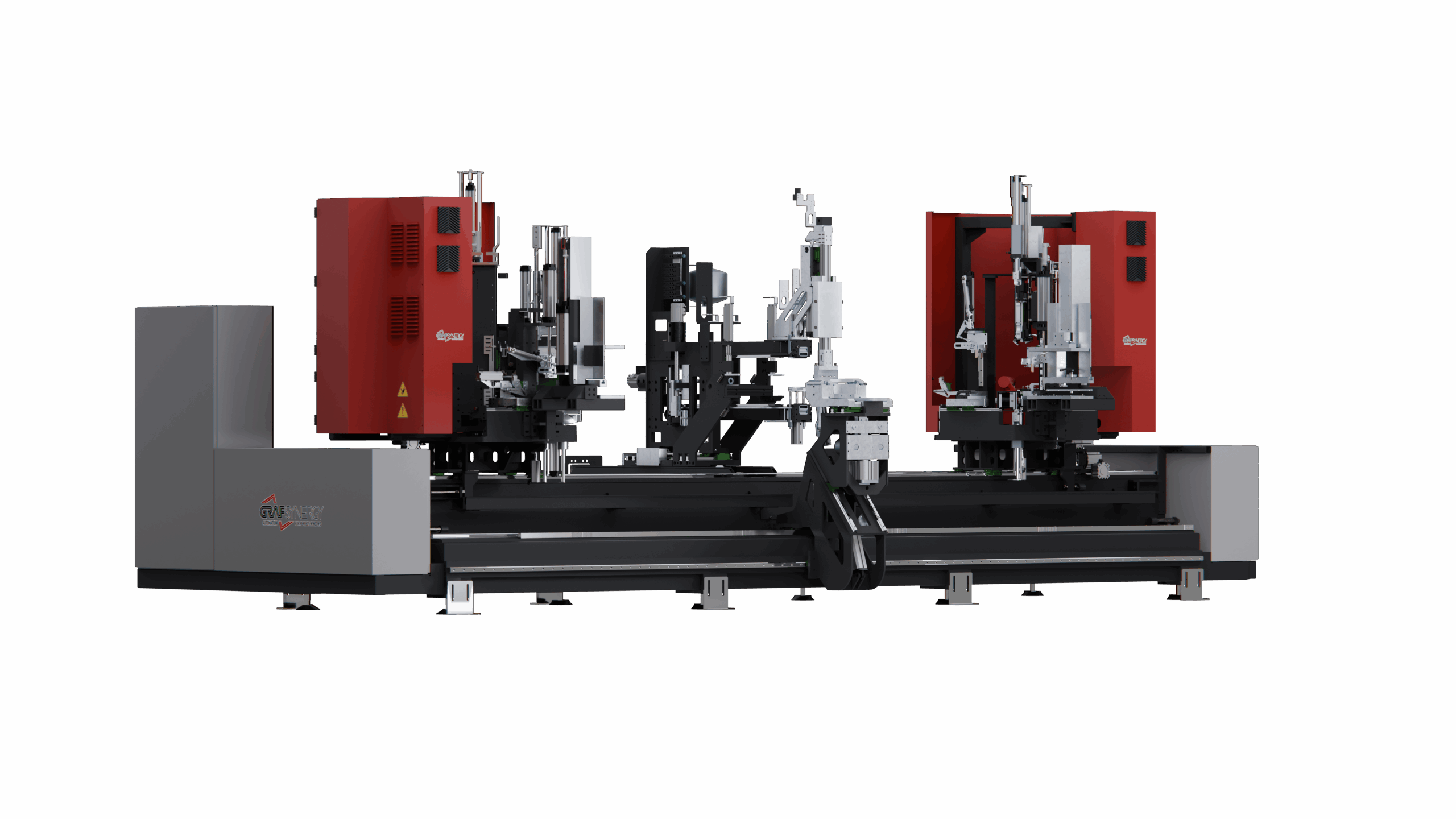

The SL3 FF TV is not just a welding machine; it is a true production centre for PVC windows with a welded “V” transom. This inline 3-head machine allows for the welding of both outer corners of the frame and the central transom in a single cycle, ensuring a flawless finish without the need for touch-ups.

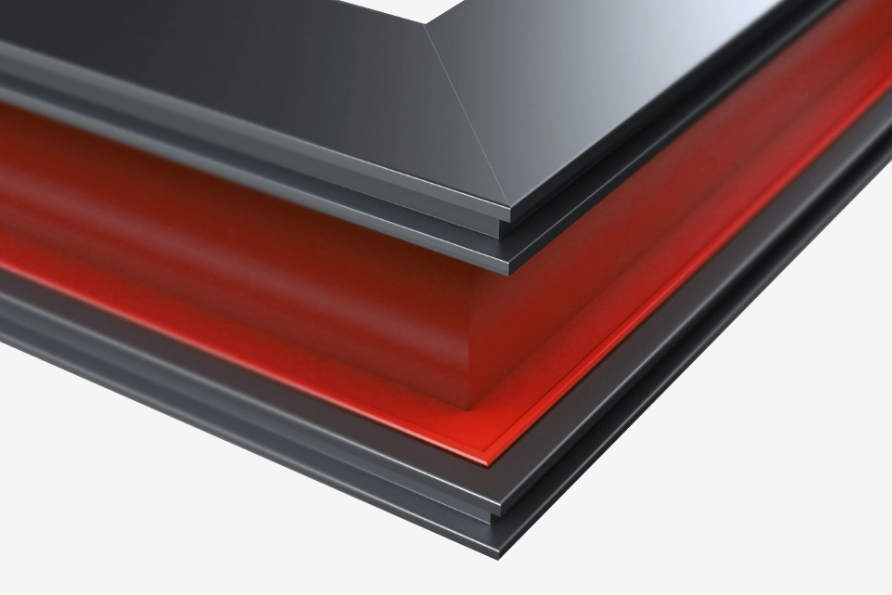

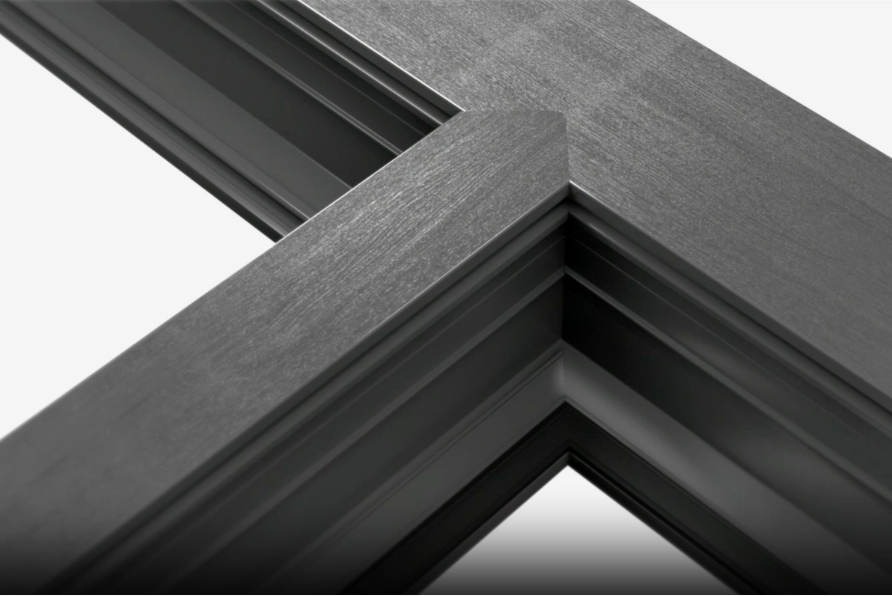

Designed for markets that require welded crosspieces with superior aesthetics, it incorporates the patented V-Perfect technology, which eliminates any visible seams even on film-coated, painted, or specially coated profiles (acrylics, aluminium, wood effect).

5 Reasons to Choose SL3 FF TV

- 3 welds in 1. It simultaneously joins 2 corners at 45° and 1 central cross member, using Notch Transom Welding technology.

- V-Perfect on every surface. Perfect on painted PVC, film-coated surfaces, acrylic, aluminium, or wood effect: invisible welding without touch-ups.

- No finishing required. The machine comes with a finished frame: no need for a cleaner, parts rotation table, or further processing.

- Automatic Calibration. Active system for compensating tolerances on cutting (2 mm) and profile height (0.5 mm).

- Maximum efficiency. With just 1 operator and up to 1 cycle every 180 seconds*, it reduces time and costs. (*depending on profile, curb, and load)

Product Details

The SL3 FF TV is not just a welder; it is a true production centre for PVC windows with a welded ‘V’ transom. This inline 3-head machine allows for the welding of both outer corners of the frame and the central transom in a single cycle, ensuring a perfect finish without the need for touch-ups.

Machine dimensions

Length: 3,600 mm

Width: 7,000 mm

Height: 2,500 mm

Weight: 5.000 Kg

Power supply

Installed power: 25 kW

Voltage: 415 V

Air consumption per cycle: 600 NI/min

Operating pressure: 7 bar

Operational features

Composition: 3 Inline Heads

Welding type: 2 corners + 1 cross in V

Operators required: 1

Cycle time: up to 1 cycle/180 seconds*

Seal machined directly during welding

Working dimensions

Frame:

- Maximum dimensions: 3,200 mm

- Minimum dimensions: 400 x 750 mm

Profile:

- Height: 60 – 82 mm

- Width: 60 – 110 mm

- Standard traverse: width 70 mm

Optional features and available configurations

- Production monitoring (changeover times, unloading, cycle)

- Cordless welding fume extractor

- Data Import Conversion Software

- Electronic contour control system

Technology and Automation

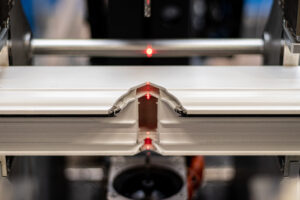

The SL3 FF TV integrates all welding functions into a single automatic cycle: high-speed milling, positioning at heights, melting, compression, cooling, and profile release.

The positioning of the upper counter-support is managed by a magnetic locking system. The burn is adjustable (5-6 mm), and all tolerances are automatically compensated.

The ideal solution for those seeking productivity, precision, and uncompromising aesthetic quality, with full compatibility for Industry 4.0.

Contact us to find out if the SL3 FF TV is the right solution for your production.