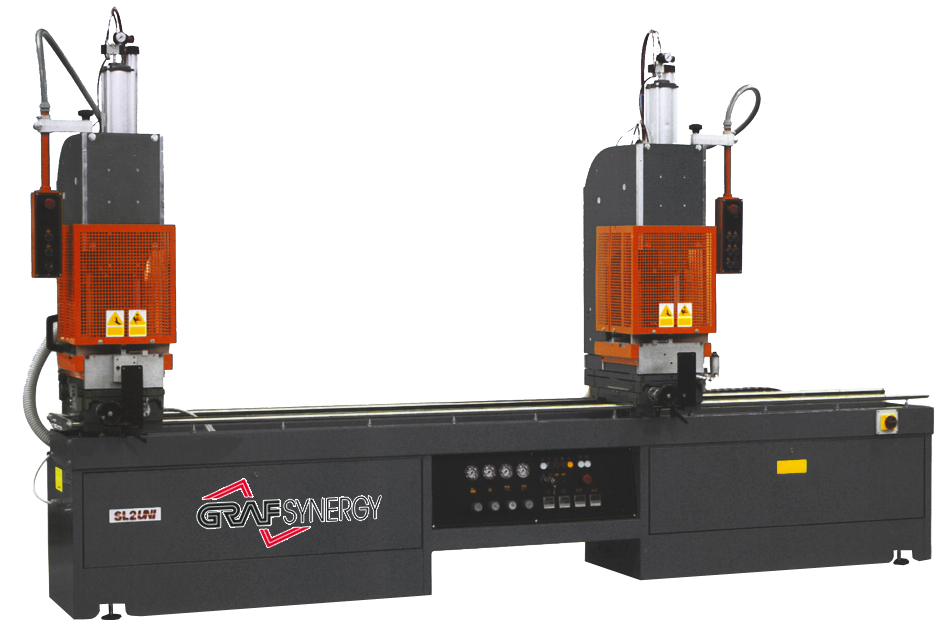

SL2V E

Variable angle double-head welding machine for custom fittings

The versatile solution for out-of-square profiles, with precise welding from 35° to 180°.

Perfect if you’re looking for a car that…

- Welding profiles out of square with angles from 35° to 180°

- Allows simultaneous welding of 2 corners at 90°

- Work with ‘C’ elements precisely.

- Maintains consistent curbs even on challenging profiles.

- It can be operated by a single operator using simplified commands.

- Integrate electronic systems for comprehensive cycle management.

Request the technical brochure now or speak with an expert.

The versatile solution for out-of-square profiles, with precise welding from 35° to 180°.

The SL2V E is a dual-head welder – one fixed and one movable with variable angle – developed by GRAF Synergy to meet the most complex production needs in the PVC window and door sector.

It is capable of welding single angles from 35° to 180° or two 90° angles in a single cycle, providing versatility, robustness, and maximum geometric precision even on out-of-square or “C” shaped elements.

Equipped with electronic temperature control, digital controls, and quick replacement of templates, the SL2V E represents a strategic investment for those seeking reliability, operational flexibility, and consistent quality.

5 reasons to choose SL2V E

- Uncompromising versatility. It allows welding on non-orthogonal angles (from 35° to 180°), making it perfect for special frames.

- Precise and consistent edge. Adjustable limit knives from 0.2 to 2 mm: aesthetic quality even on complex profiles.

- Electronic temperature control. Intelligent temperature management for consistent results over time.

- Simple and intuitive operation. Digital controls and automatic cycle: a single operator can manage the entire process.

- 5. Quick Replacement of Counter Templates. Fast and error-free format change system.

Product Details

The SL2V E is a dual-head welding machine – one fixed and one mobile with variable angle – developed by GRAF Synergy to meet the most complex production needs in the PVC window and door sector.

It is capable of welding single angles from 35° to 180° or two 90° angles in a single cycle, offering versatility, robustness, and maximum geometric precision even on out-of-square or ‘C’ shaped elements.

Dimensions

Length: 3,950 mm

Width: 800 mm

Height: 2,100 mm

Weight: 850 Kg

power supply and Consumption

Installed power: 5.2 kW

Voltage: 400 V

Air consumption per cycle: 140 Nl/min

Minimum pressure: 7 bar

Performance

Cycle: automatic

Operations: manual

Operators required: 1

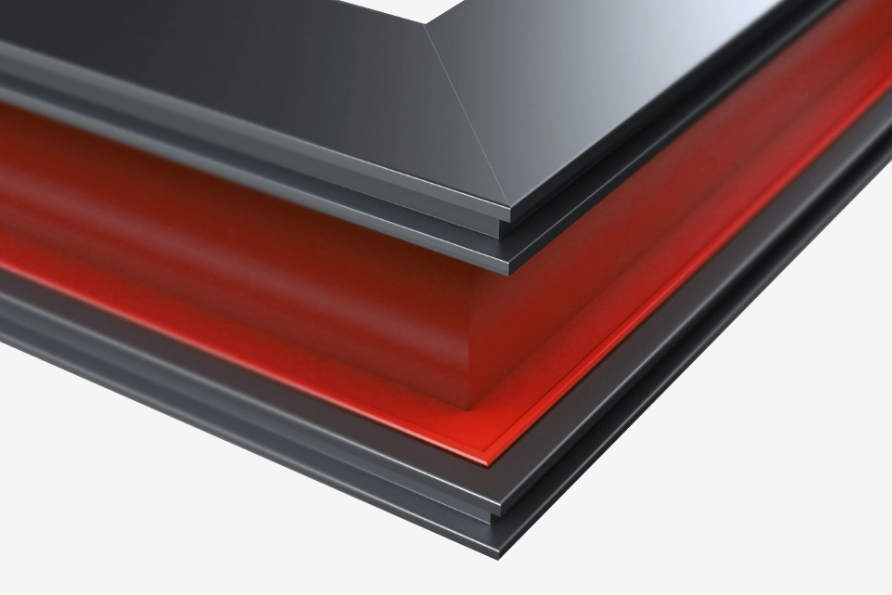

Workable profiles

Height: 40 to 200 mm

Width: 40 ÷ 130 mm

Length between heads: 420 ÷ 3.280 mm

Supported features and processes

- Single welding at a variable angle (35°-180°)

- Double welding at 90°

- Welding C-shaped elements

- Comprehensive electronic temperature control

Cycle managed by integrated digital controls

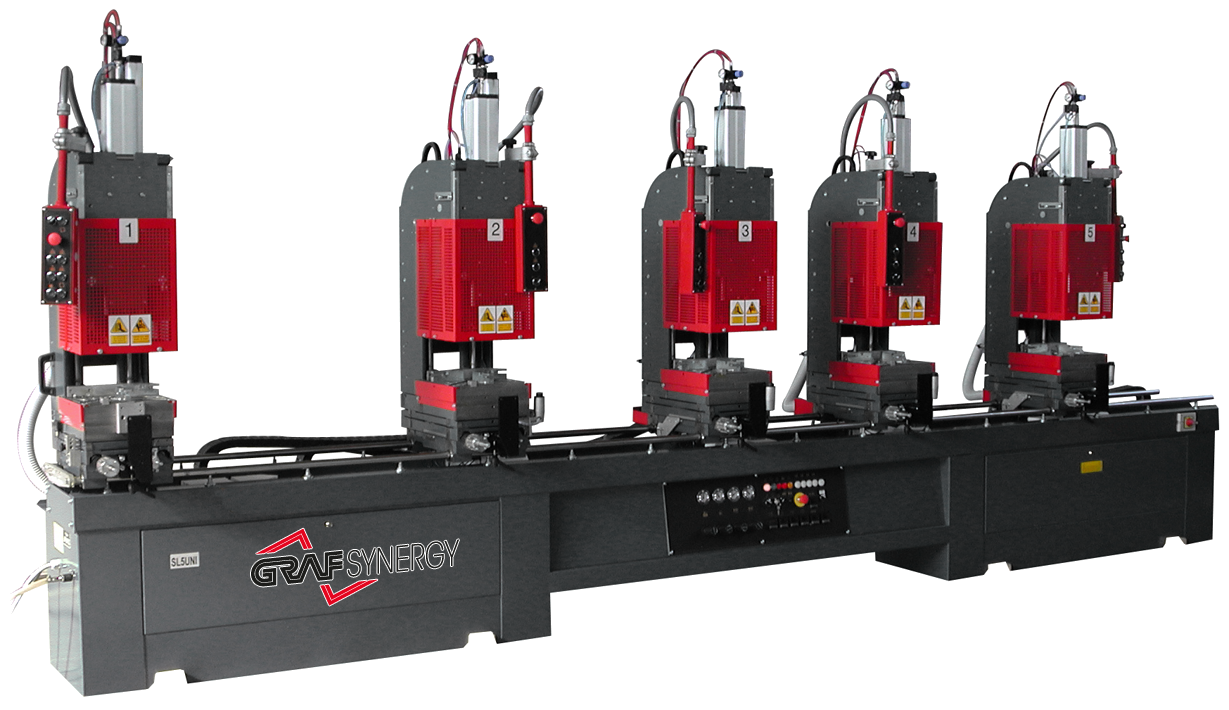

Optional available

Compact base version measuring 2,450 mm

Right head extension L = 270 mm

Additional support for profile holder arms (1 per head) in automated and flexible work cells, adaptable to the most advanced production needs.

Technology and automation

Quick template replacement with a quick-release system

Integrated digital control

Cycle display on a simplified screen

Ready for modular production flows and customised configurations.

Discover the productivity advantage of the SL2V E. Contact us for a demo or to receive the technical brochure: your customised production line starts here.