SL2 FF DIA

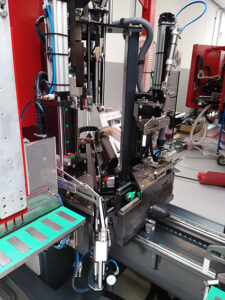

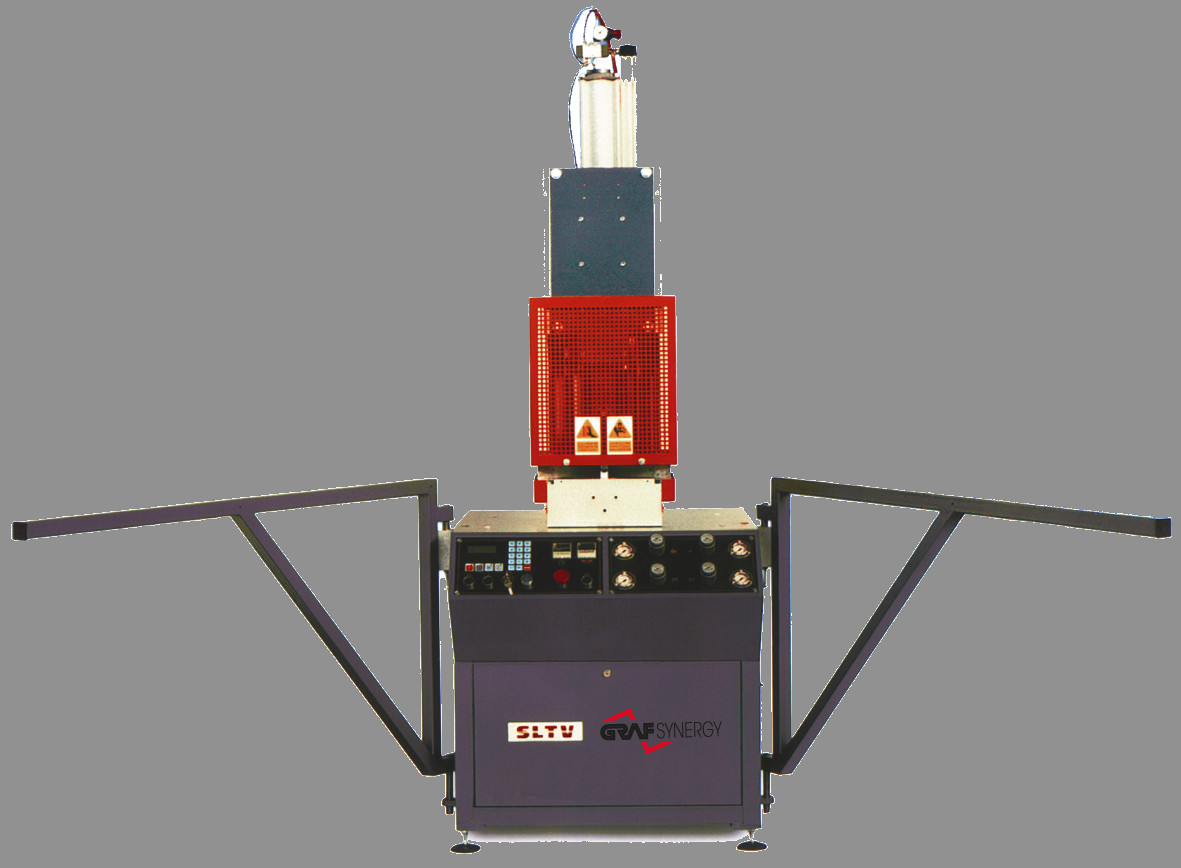

CNC Double-Head Welder for PVC Windows without a Sill

The world’s first to weld two corners simultaneously, without a bead.

Perfect if…

- Do you want to remove the curb at the corners to achieve impeccable aesthetic quality?

- Complex profiles, coated or with non-weldable inserts.

- You need to reduce cycle times and manual rework.

- Manage dimensional tolerances between profiles and seek automatic correction.

- Do you want to simplify welding by assigning it to a single operator?

Request the technical brochure now or speak with an expert.

The world’s first to weld two corners simultaneously, without a bead.

The SL2 FF DIA is the first and only CNC horizontal welding machine with 2 heads capable of completely eliminating the weld seam, ensuring PVC fittings with a perfect aesthetic finish even on coated profiles or with non-weldable inserts.

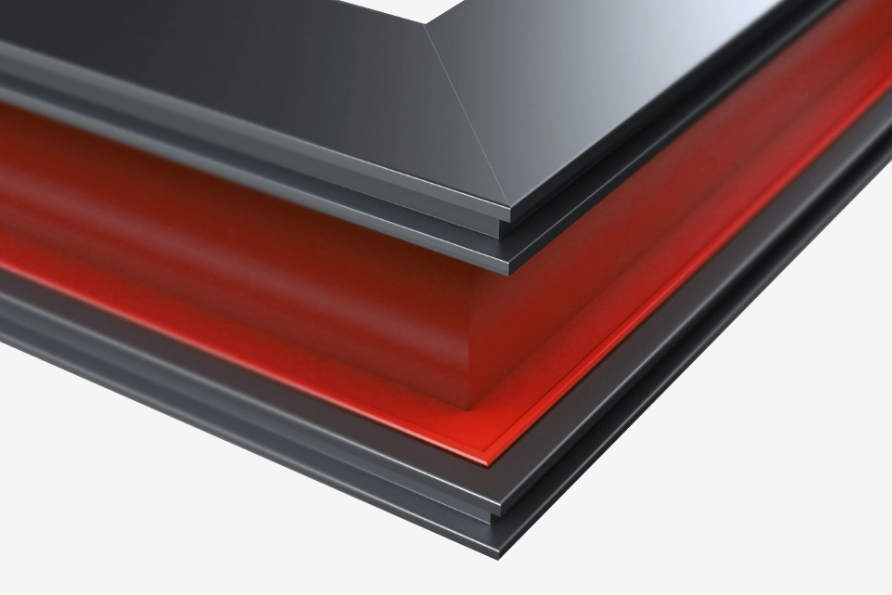

Thanks to the patented V-Perfect technology, it is ideal for processing painted PVC profiles, laminated surfaces, acrylics, or combinations with materials such as aluminium, wood, or fibreglass. The result? Smooth, continuous corners, ready for assembly, without the need for touch-ups or reworking.

Compact, fast, and fully automated, SL2 FF DIA is designed to maximize productivity with a single operator, eliminate post-processing, and seamlessly integrate into Industry 4.0 lines.

5 reasons to choose SL2 FF DIA

- Seamless Welding. Thanks to the patented V-Perfect system, the finish is perfectly smooth without removing any material.

- No post-welding rework. The profile comes out of the machine already finished: no cleaning, milling, or manual correction is required.

- One operator only. Fully automated management: the operator loads and unloads, and the machine takes care of the rest.

- Maximum material compatibility. Perfect for coated profiles, acrylics, films, painted surfaces, or those with aluminium or fibre inserts.

- Automatic Tolerance Compensation. An intelligent system calibrates profiles and corrects any dimensional differences in real-time.

Product Details

The SL6 FF TR fully automates seamless welding, even on profiles with non-weldable inserts (fibreglass, aluminium, resin).

Machine dimensions

Length: 6,000 – 7,500 mm

Width: 3,000 mm

Height: 2,400 mm

Weight: 2.500 – 3.500 kg

Performance

Cycle time: up to 1 frame every 140 sec*

Operators required: 1

* Varies based on profiles, seals, and configuration

power supply and consumption

Installed power: 16.5 kW

Voltage: 400 V

Air consumption: 600 Nl/min

Minimum pressure: 7 bar

Operators required

1

Profiles and workable dimensions

Profile Dimensions

- Altezza: 35 ÷ 180 mm

- Width: 40 to 130 mm

Weldable side between heads

- Minimum: 250 mm (with 70 mm profiles)

- Max: 3,500 mm (extendable upon request)

Cycle time

- Up to 1 frame every 250 seconds (depending on profile and curb)

Optional features and custom configurations

To meet specific needs, SL2 FF DIA is configurable with:

- Weldable increase between heads over 3,500 mm (subject to technical verification)

- Integrated vacuum for seamless welding

Technology and automation

SL2 FF DIA is:

- Equipped with high-precision CNC

- Equipped with a simple and intuitive interface

- Integrable into automated production systems

- Prepared for Industry 4.0, with support for remote assistance and remote monitoring

Compatible with ERP management systems for complete traceability

Do you want to eliminate welding defects and revolutionise the finish of your fixtures? Request the brochure or book a demo with our experts: SL2 FF DIA is the ultimate welder for those aiming for perfection.