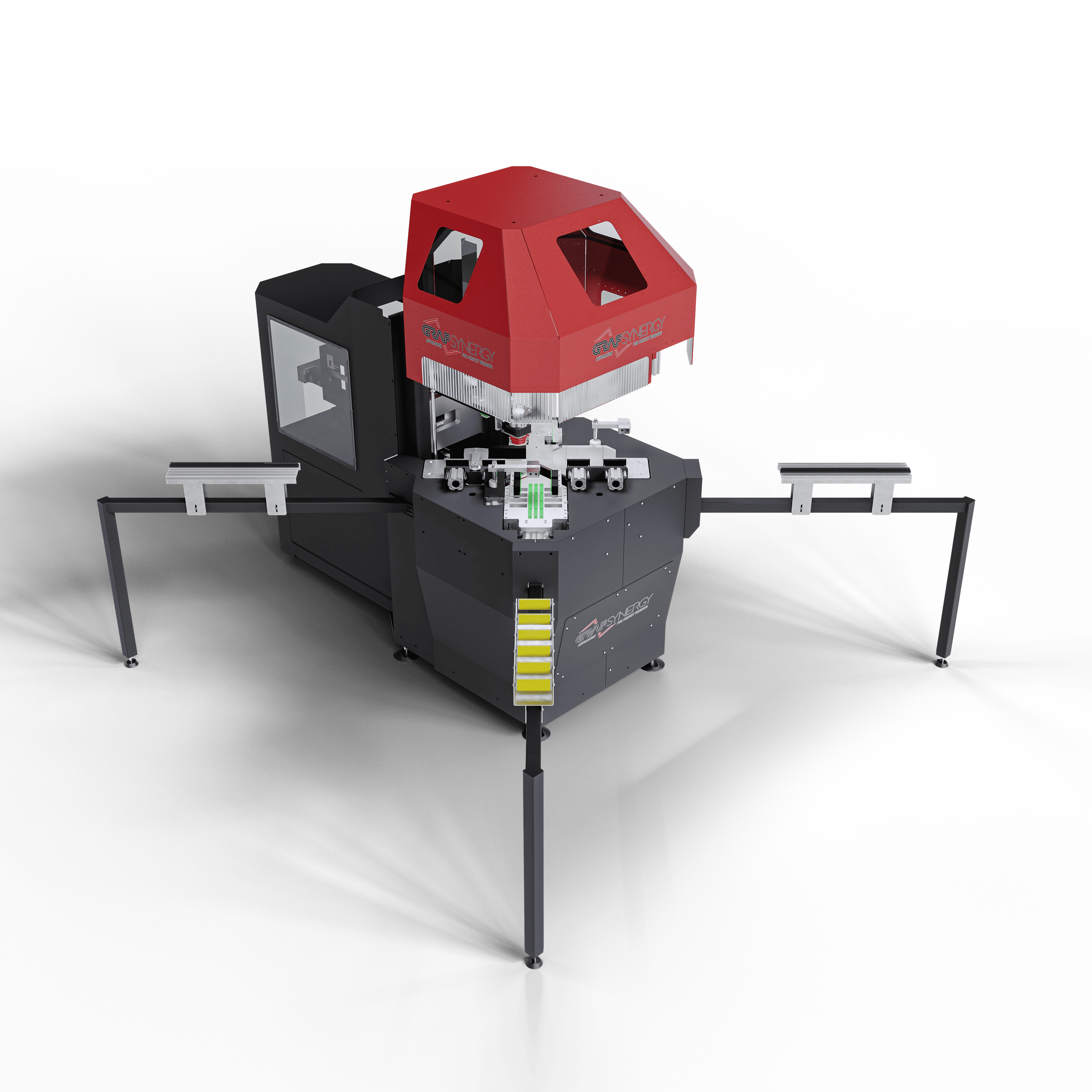

SL FF RB

CNC Welder with Single Head for 180° Reverse Butt Joints

The first CNC welder for frames with a 180° inline cross member.

Perfect if:

- Welding frames and crossbars aligned at 180° in a single cycle.

- Eliminate post-welding cleaning and manual touch-ups.

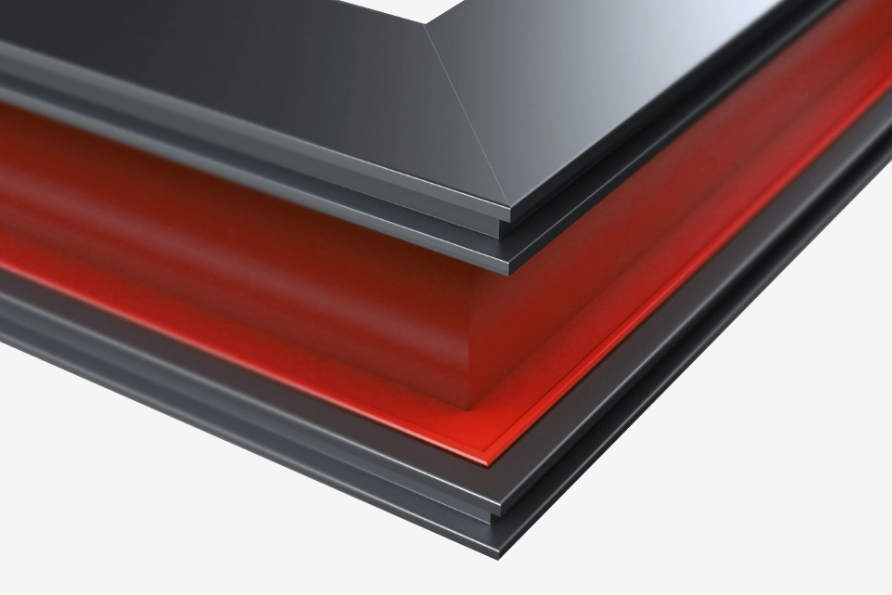

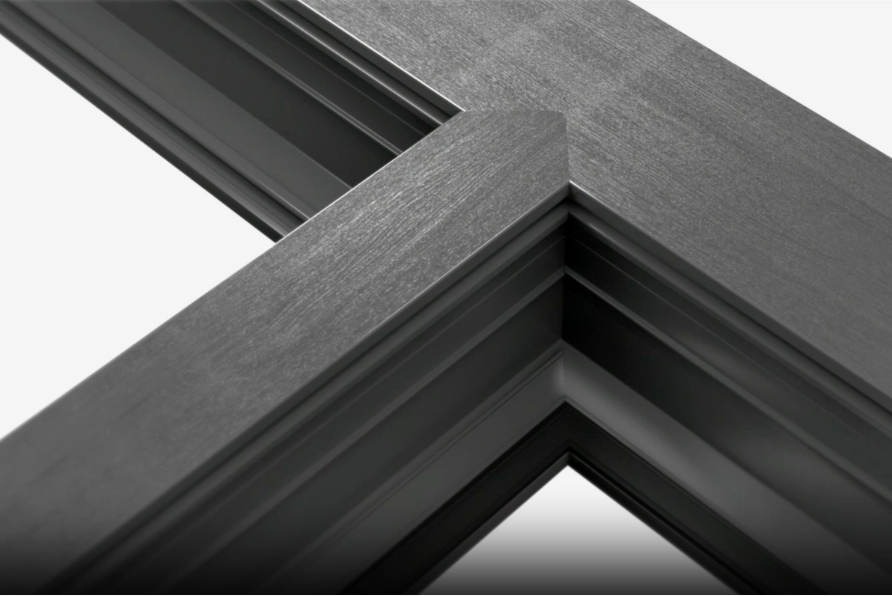

- Working with PVC using films, paints, acrylics, laminates, and aluminium or wood coatings.

- Reduce space, working hours, and labour.

- Automatically compensate for profile tolerances

Request the technical brochure now or speak with an expert.

The first CNC welder for frames with a 180° inline cross member.

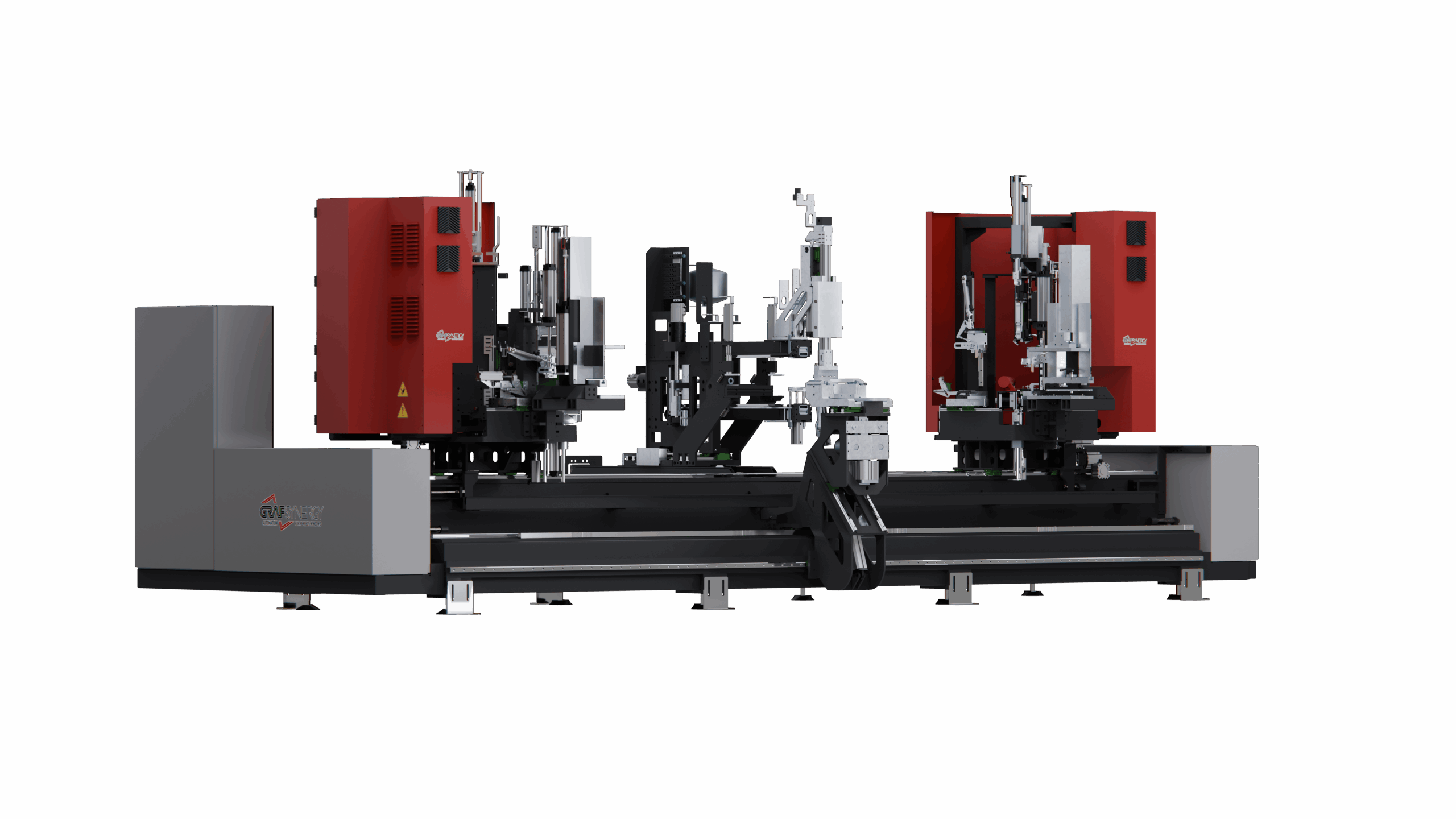

The SL FF RB is the first CNC welding machine with a single head designed to perform 180° reverse butt welds, enabling the seamless inline joining of PVC frames and crossbars, ensuring a perfectly flat and continuous surface.

Equipped with V-Perfect technology, it can weld complex and coated profiles without leaving visible seams, even when working with non-weldable materials such as fibre, aluminium, or resins. In just one cycle, it produces a complete frame that is aesthetically flawless and ready for assembly.

5 reasons to choose SL FF RB

- Suitable for all materials and coatings. Perfect for profiles with anodised, acrylic, painted, or wood/aluminium finishes.

- Welds, finishes, and delivers. Eliminates the need for a cleaner, rotating table, or touch-ups: the piece is complete on the first attempt.

- Labour Reduction. Requires only one operator for loading profiles: everything else is automated.

- Minimal footprint. Compact structure designed for spaces with limited room.

- Integrated automatic calibration. Automatically compensates for dimensional variations of up to 2 mm.

Product Details

The SL FF RB is the first CNC welding machine with a single head designed to perform 180° reverse butt welds, enabling the seamless joining of PVC frames and crossbars while ensuring a perfectly flat and continuous surface.

Machine dimensions

Length: 2,300 mm

Width: 2,000 mm

Height: 2,700 mm

Weight: 1.400 kg

Power supply

Installed power: 6 kW

Voltage: 415 V

Air consumption per cycle: 600 NI/cycle

Operating pressure: 7 bar

Operational features

Composition: 1 CNC Head

Welding Type: frame joint + 180° cross (reverse butt)

Operators required: 1

Cycle time: up to 1 weld every 140 seconds

Working dimensions

Weldable side:

- Minimum: 300 mm

- Maximum: unlimited (no machine limit)

Weldable profile:

- Height: 60 – 100 mm

- Width: 60 – 110 mm

Optional available

- Weld fume extractor without a collar

TECHNOLOGY AND AUTOMATION

SL FF RB uses V-Perfect technology to create completely flat joints, free from seams or visible defects.

CNC automation allows for the adjustment of all processing parameters and compensates for the tolerances of profiles, ensuring consistent aesthetic quality even on unconventional materials.

It is the ideal solution for custom productions, complex fixtures, or assembly lines where aesthetic quality makes a difference.

Contact us to find out if the SL FF RB is the right solution for your production.