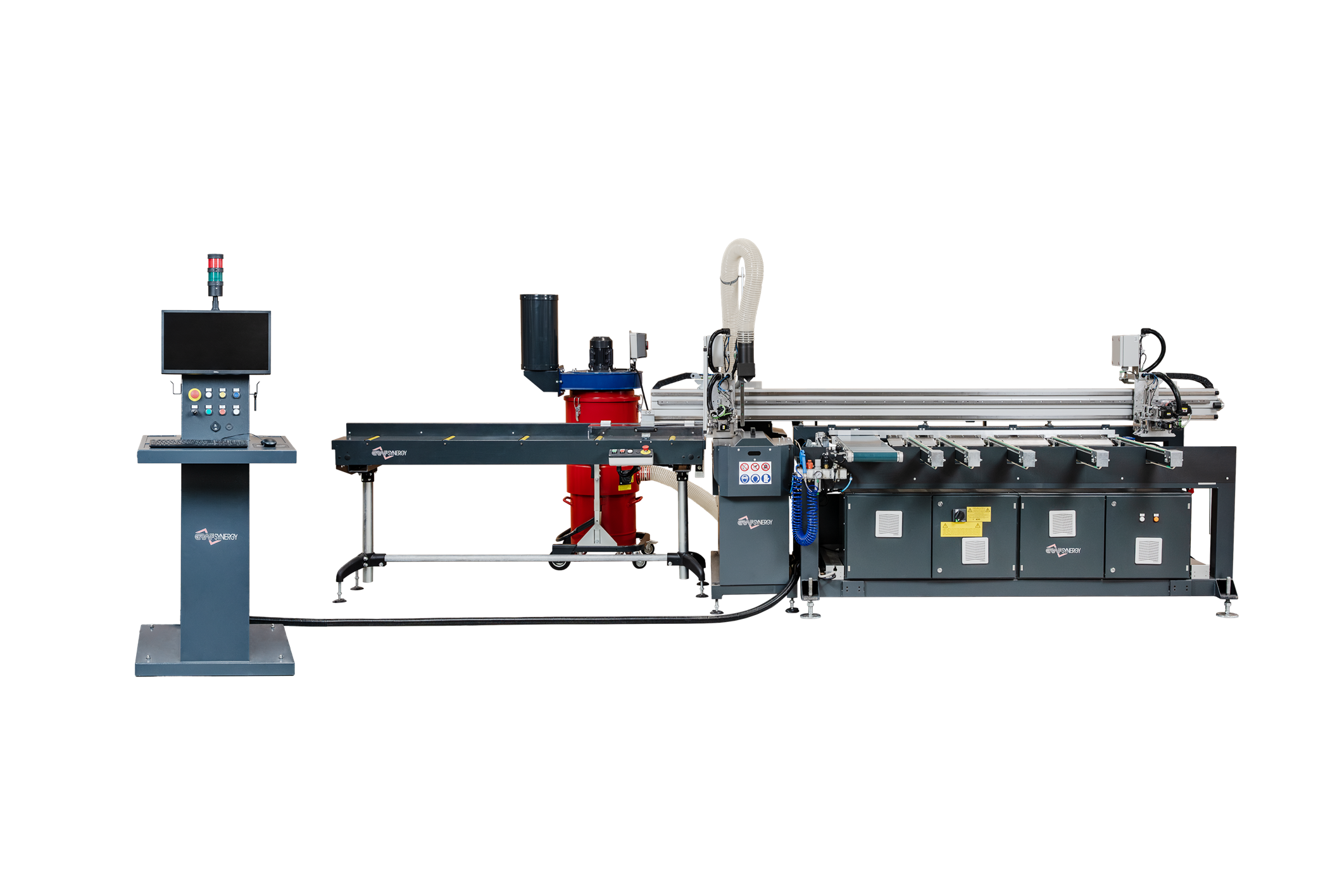

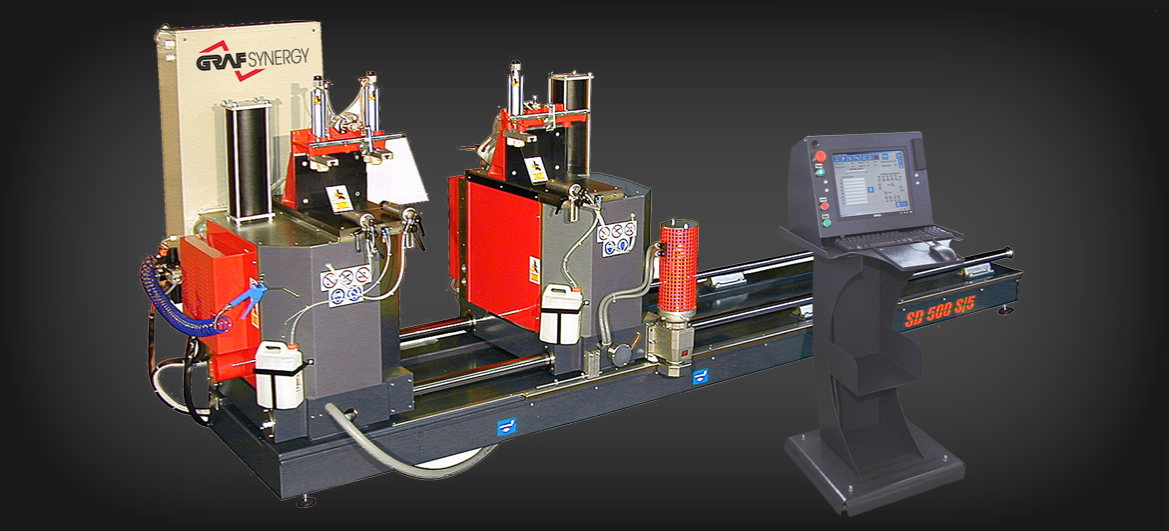

SD 500 S7

High-capacity double-head saw for PVC and aluminum

Fast and precise cuts, even on double profiles with variable angles

Perfect if…

- You manufacture PVC or aluminum windows and doors and are looking for maximum cutting flexibility

- You want to cut two profiles simultaneously to increase productivity

- You need a precise, stable, and reliable machine even at high volumes

- You require quick angle changes without adjusting the lengths

- You work with the need for intermediate cuts thanks to dedicated mechanical stops

Request the technical brochure now or speak with an expert

Fast and precise cuts, even on double profiles with variable angles

The SD 500 S7 is a double-head hydro-pneumatic saw with electronic control, designed for precise and repeatable cutting of PVC and aluminum profiles.

Equipped with one fixed head and one movable head with automatic positioning via a controlled axis, it enables fast and flexible operations, ideal for high-frequency industrial production.

The robust steel and aluminum structure ensures stability and long-term durability, while the vertical rise system of the Ø 500 mm blades with internal pneumatic tilting (from 90° to 45°) eliminates the need for manual corrections during angle transitions.

Control is managed through a sliding control panel with two-hand operation, ensuring maximum safety and ergonomics.

5 reasons to choose the SD 500 S7

- Ultra-robust structure. Steel and aluminum frame designed for stability and precision even under intensive use.

- Simultaneous double-profile cutting. Ø 500 mm blades with extended stroke allow processing of two pieces at the same time.

- No measurement correction needed. Internal pneumatic tilting from 90° to 45° enables quick and precise angle changes without manual adjustments.

- Cutting versatility. Handles aluminum and PVC profiles, with multiple configurations and intermediate cuts thanks to mechanical stops.

- Optimized extraction and clamping. Equipped with 4 Ø 100 mm chip extraction outlets and vertical/horizontal pneumatic clamps to firmly secure profiles.

Product Details

The SD 500 S7 delivers precise and clean cuts on single or double profiles, even with complex angles. The two vertical rise blades and the hydro-pneumatic system ensure stability and consistent quality. The two-hand control, combined with the sliding control panel, optimizes operator ergonomics.

Dimensions

Length: 4,500 mm

Width: 1,300 mm

Height: 1,650 mm

Weight: 1,050 kg

Operating performance

Mode: manual or automatic (cutting list import via USB or Ethernet network)

Usable cutting length: from 325 mm to 5,300 mm*

Operators required: 1

(*maximum length varies depending on the base: 3,300 / 4,300 / 5,300 mm)

Power supply and consumption

Installed power: 6 kW

Voltage: 400 V three-phase

Minimum pressure: 7 bar

Air consumption per cycle: 40 Nl/min

Profiles that can be processed

Materials: PVC and Aluminum

Configurable cuts: +45°/-45°, +45°/90°, 90°/-45°, 90°/90°

Optional features and available configurations

- Bases of 4,300 or 5,300 mm

- Roller conveyors for fixed and movable heads

- Two-bag dust extractor (4 outlets Ø 100 mm)

- Mechanical stops for short and pointed cuts

- Short and pointed cut unit with pneumatic waste removal

- Manual labeling machine

- Custom counter-profiles (single or double cut)

- Software for cutting small profiles and extra-long profiles

- Fly Optimizer: software for dynamic bar optimization

Technology and Automation

Controlled by an advanced electronic system, the SD 500 S7 allows automatic management of the cutting cycle and direct import of production data. It is ready for integration into Industry 4.0 systems with remote assistance, traceability, and digital management.

Contact GRAF Synergy today to receive the detailed brochure and discover how the SD 500 S7 can enhance the productivity of your cutting department.