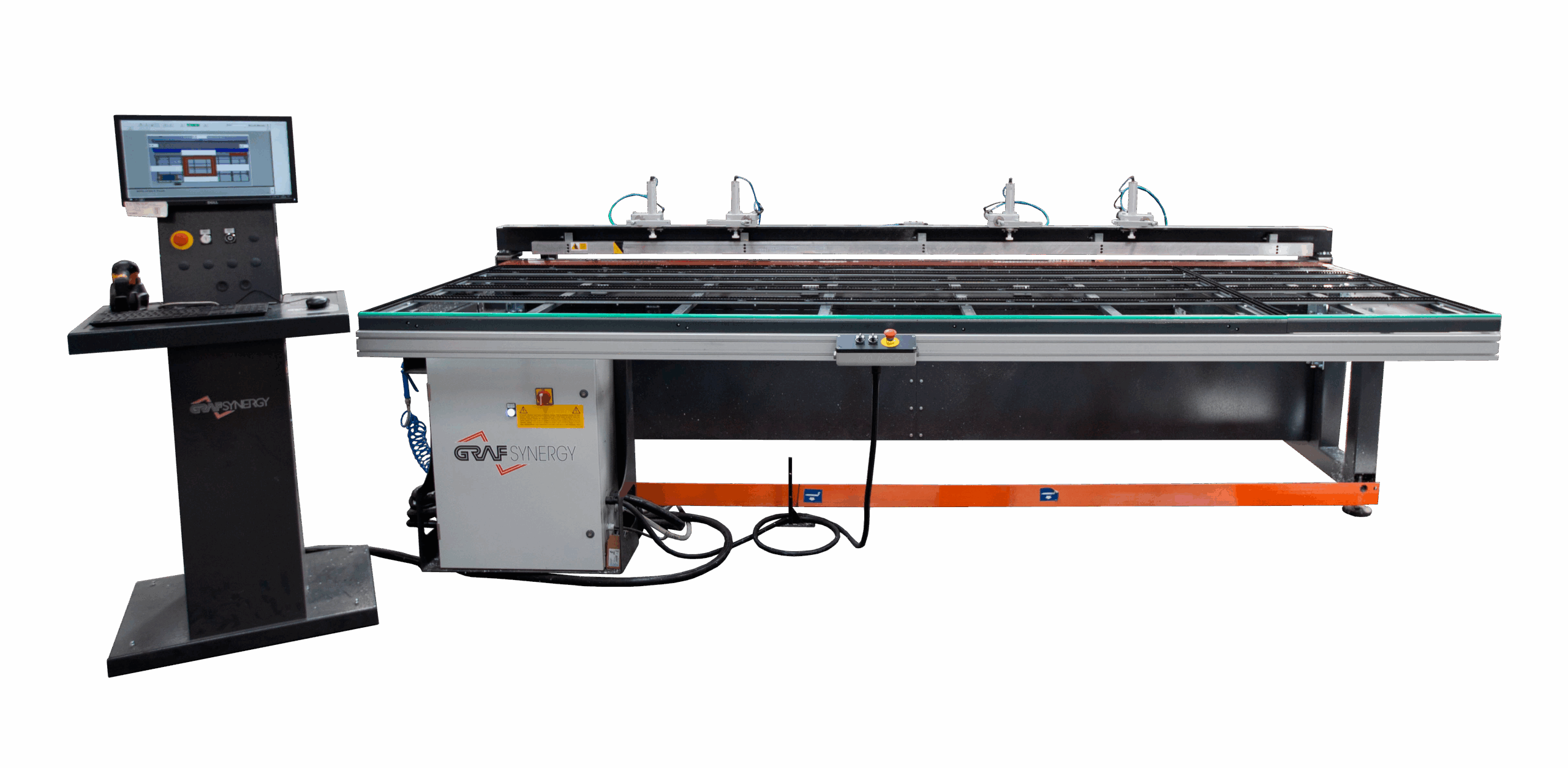

RFA 300 CNC

Horizontal automatic cutting machine for PVC frames

Perfect trimming on all four sides, without any manual intervention.

Perfect for…

- Fully automatic trimming on all four sides of the frame

- Scratch-resistant plan and motorised straps for gentle handling

- 300 mm blade with CNC feed for perfect cuts

- Compatibility with automated lines and Industry 4.0

- Locking system with 4 rotating pneumatic clamps

Request the technical brochure now or speak with an expert.

Perfect trimming on all four sides, without any manual intervention

Designed for integration into automated production lines, the RFA 300 CNC is the horizontal trimming machine that enables the complete processing of PVC frames in a continuous cycle. Each side is trimmed with precision without the need for manual rotations, ensuring speed, repeatability, and consistent quality.

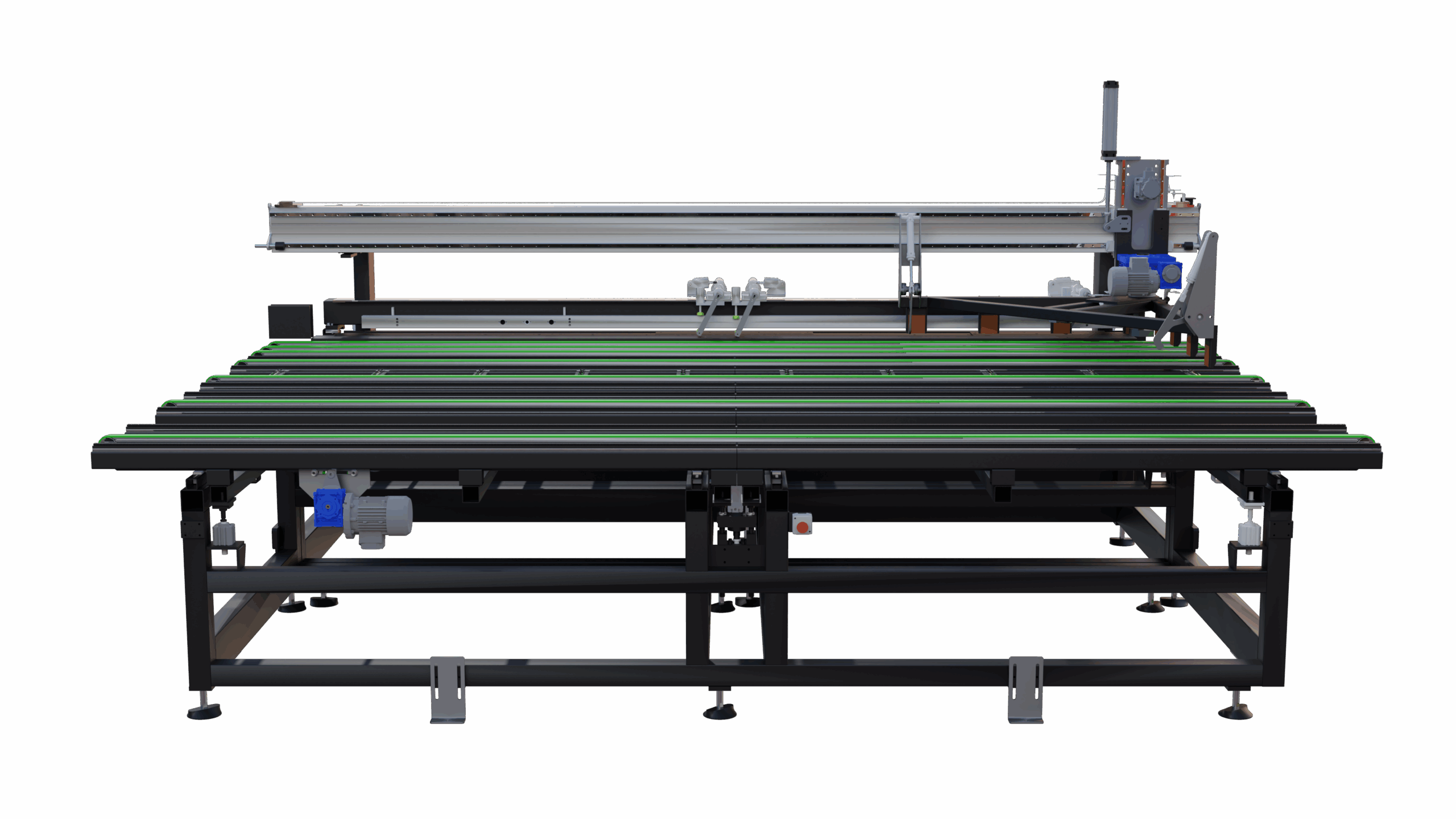

The handling of the pieces takes place on a spacious surface equipped with scratch-resistant brushes and motorised tracks, which also protect the most delicate profiles from scratches and damage.

The operational core is a 300 mm blade with electronic feed on a controlled axis and pneumatic lift, ensuring uniform trimming without vibrations.

Why choose RFA 300 CNC?

- Complete trimming in a single cycle. A system of 4 rotating pneumatic clamps securely holds the frame and automatically orients it, allowing for the sequential trimming of all four sides without manual intervention.

- Scratch-resistant surface and smooth handling. The transport of frames is carried out on motorised tracks mounted on a surface with a scratch-resistant coating, making it ideal for both film-coated and painted profiles.

- High-precision cutting with CNC blade. The blade feed is managed by numerical control, featuring automatic adjustment of the trimming thickness through electronic movement of the stop gauge.

- Smart management and intuitive interface. The machine is operated by a industrial PC using proprietary GRAF Synergy software. It recognises parts through data transmission from the line or a barcode reader.

- Prepared for Industry 4.0. The RFA 300 CNC is easily integrable into digitalised systems, thanks to advanced connectivity, remote management, and traceability features.

Product Details

Designed for integration into automated production lines, the RFA 300 CNC is the horizontal trimming machine that enables the complete processing of PVC frames in a continuous cycle.

Machine dimensions

Length: 4,550 mm

Width: 3,900 mm

Height: 2,300 mm

Weight: 1.800 kg

Operational Performance

Operation: fully automatic

Maximum cutting length: 3,000 mm

Maximum trimming height: 25 mm

Maximum working profile height: 82 mm

power supply and Consumption

Installed power: 5 kW

Power Supply: 400 V

Air consumption: 150 Nl/min

Minimum pressure for operation: 7 bar

Workable materials

Welded PVC frames in various sizes and finishes

Supported features and processes

The RFA 300 CNC operates autonomously:

- Complete trimming on all four sides

- Automatic removal of waste through rear evacuation.

Locking and centring the frame using rotary clamps.

Optional features and available configurations

- Waste suction system

- Morse specifications for Dormant Large profiles

- Stainless steel profiles for transporting delicate films

Advanced Automation

Every function of the RFA 300 CNC is designed for a continuous and optimised production cycle.

The combination of electronic control on axis, dedicated software, and intelligent clamping systems makes the machine a strategic asset for any automated welding line.

Request a personalised consultation

Contact the GRAF Synergy team now to receive a demo or a free assessment: discover how to take your finishing department to the next level with the RFA 300 CNC.