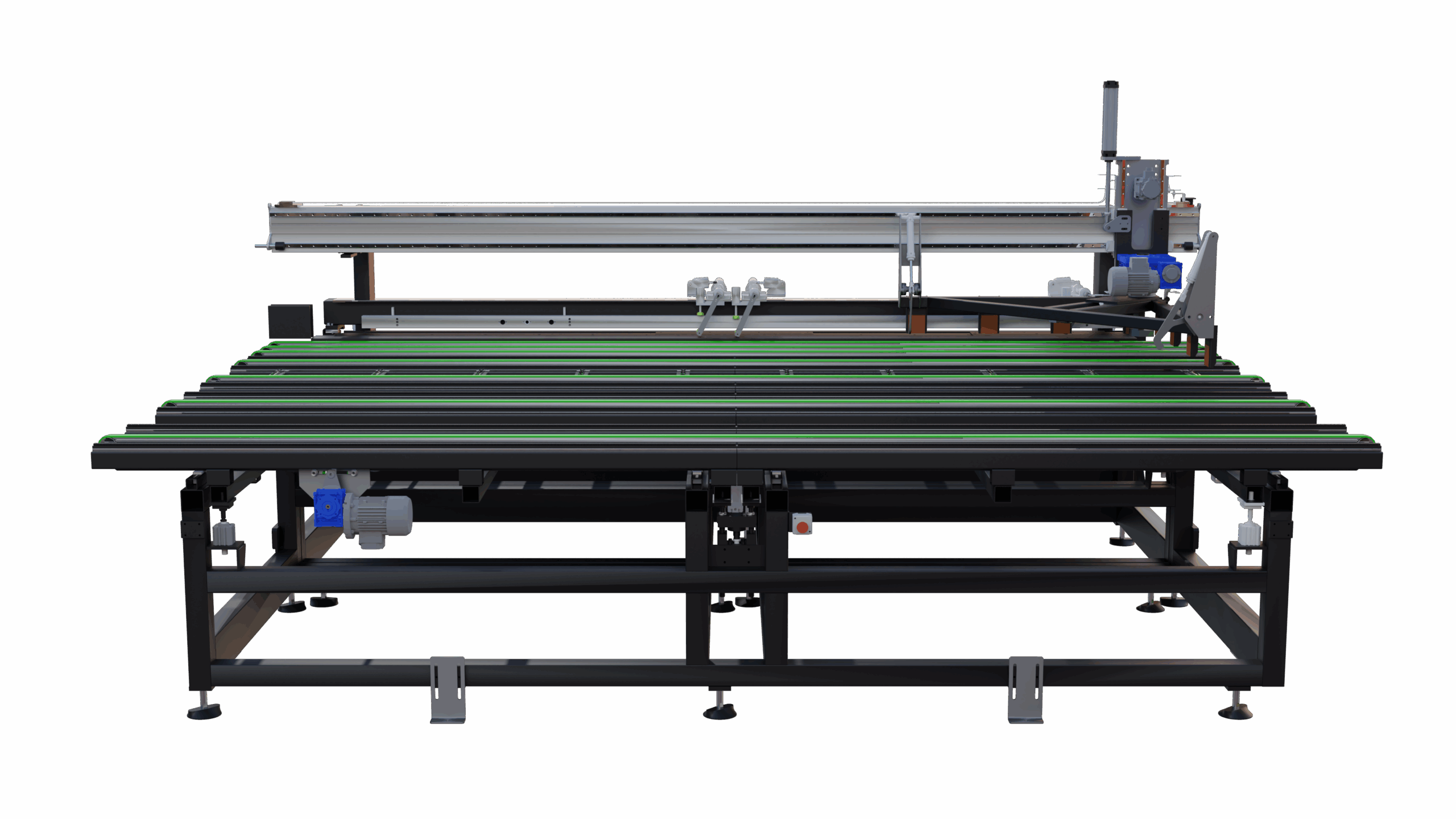

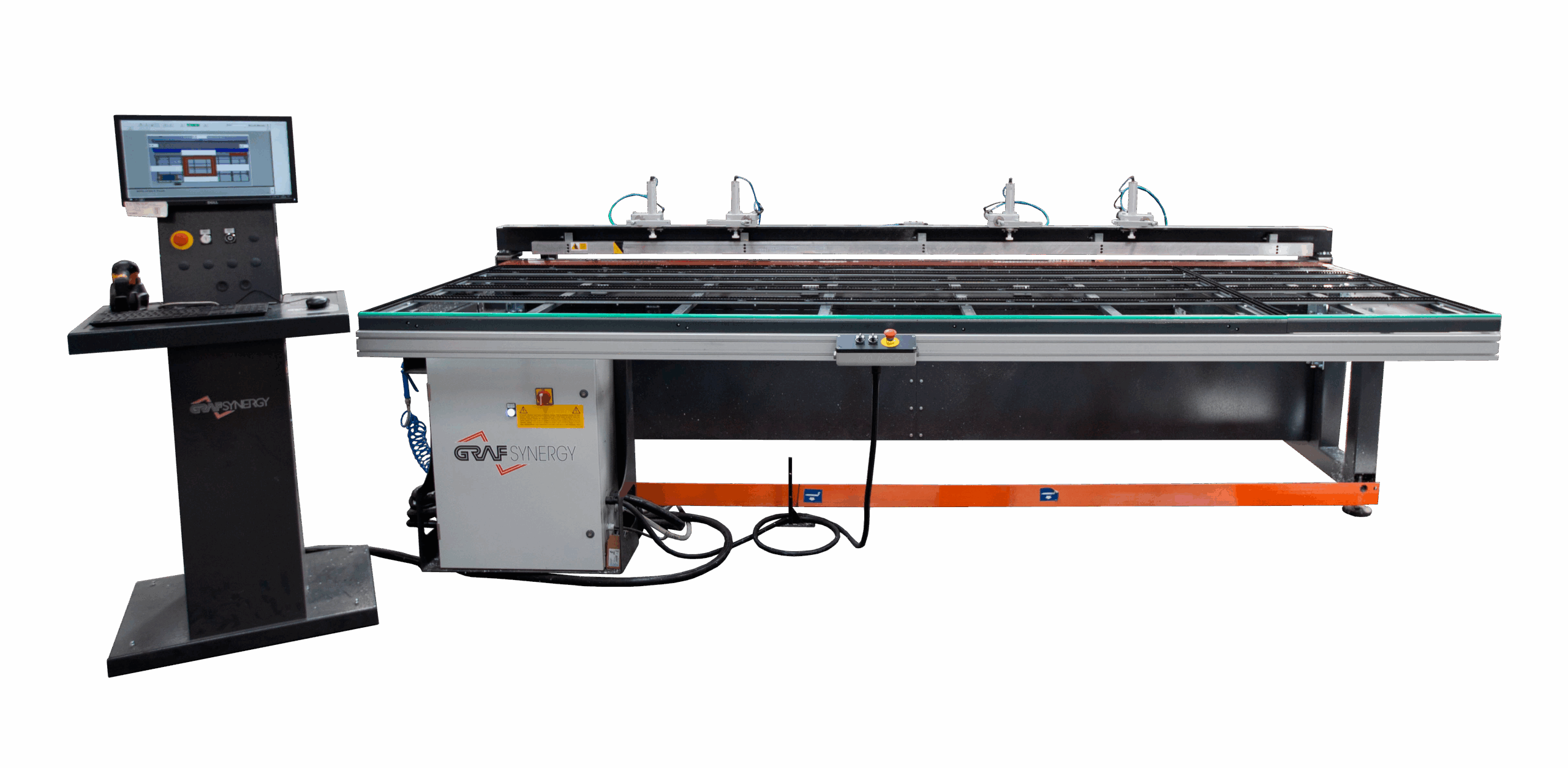

RF 330 GS

Horizontal cutting machine for PVC frames with welded PVC corners

Precision, safety, and complete control in frame trimming

Perfect if…

- Do you want to improve the finish quality of your PVC frames?

- You need a machine that is easy to use even for inexperienced operators.

- You need to reduce trimming times without compromising accuracy.

- Are you looking for a compact solution to optimise space in your workshop?

- You work with welded profiles that require secure and stable locking.

- Do you want to automate order management through barcode scanning?

Request the technical brochure now or speak with an expert.

Precision, safety, and complete control in frame trimming

The RF 330 GS is the horizontal trimmer designed by GRAF Synergy to optimise the trimming phase of welded PVC frames. Compact, precise, and fully software-controlled, it is the ideal solution for those seeking a reliable, easy-to-use machine that ensures a perfect finish on every piece.

Equipped with a spacious work surface featuring anti-friction and anti-scratch strips, it ensures smooth handling of frames, reducing the risk of damage during processing. The automatic clamping via 4 pneumatic rotating vices secures the frame in place with maximum stability, guaranteeing clean, vibration-free cuts.

The technological heart of the machine is the Ø 300 mm blade, featuring electronic feed with axis control and pneumatic lift: a system that combines micrometric precision with operational speed. The positioning of the reference stop is also electronic, ensuring a perfect definition of the trimming thickness. All of this is managed by intuitive software, accessible via a touch PC, with the capability to read barcodes for automating the retrieval of processing tasks.

Thanks to the electronic variation of cutting speed via an inverter, the operator can adjust the intervention according to the type of profile, always achieving the best compromise between speed and finish quality.

5 reasons to choose the RF 330 GS

- Maximum precision in cutting. Electronic feed with axis control and automatically adjustable stop: every trimming is carried out with minimal tolerances.

- Superior finish quality. Inverter for cutting speed adjustment: optimises processing based on the type of profile and enhances the final result.

- Secure and vibration-free locking. A system of 4 pneumatic rotating clamps that keeps the frame perfectly stable throughout the entire processing.

- Ease of use and intuitive control. Dedicated software, touch interface, and barcode reading capabilities for streamlined and error-free management.

- Compact size and easy integration. It occupies only 4.1 m x 2.2 m: perfect even for laboratories with limited space.

Product Details

The RF 330 GS is designed for trimming welded PVC frames. With a Ø 300 mm blade and electronic feed, it ensures repeatable, high-quality results on all types of profiles. The anti-friction table facilitates positioning, while the rear drop-off aids in cleaning and managing waste.

Dimensions

Length: 4,100 mm

Width: 2,200 mm

Height: 1,500 mm

Weight: 700 kg

Performance

Operations: manual

Operators required: 1

power supply and Consumption

Installed power: 3 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption: 50 Nl/min

Workable profiles

Maximum length: 3,000 mm

Maximum trimming height: 27 mm

Maximum profile height: 100 mm

Supported features and processes

Main processes:

- Automatic cutting thickness adjustment

- Horizontal side trimming of PVC frames

Optional features and available configurations

The machine can be customised with accessories that enhance productivity and integration into the production cycle. Among the most requested options are:

Barcode reader for automatic program recall

Vacuum system with 2 bags (4 outlet version Ø 100 mm)

Technology and automation

The RF 330 GS is controlled by an advanced electronic system, interfaced with dedicated software designed to simplify operations even for those without CNC expertise. The interface is intuitive, and integration with data management systems (via barcode) allows for more efficient programming and complete traceability of the processing.

Perfectly compatible with the requirements of Industry 4.0, it can be integrated into management and remote monitoring systems, thereby increasing transparency and control over the production process.

Want to discover how the RF 330 GS can enhance your production?

Download the full brochure or contact us for a personalised quote.