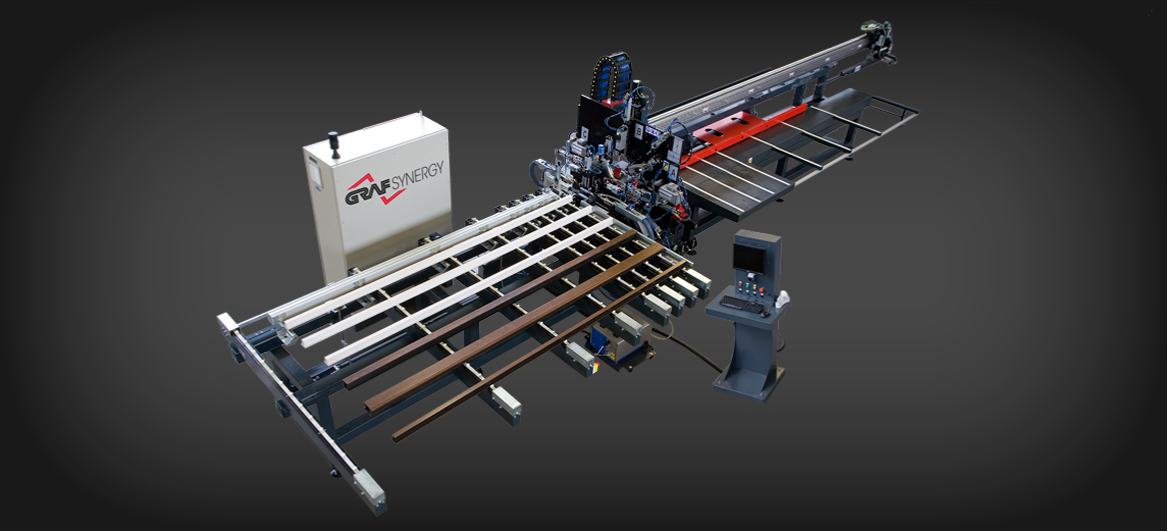

LINEAR FAB 5000

5-axis CNC machining centre for processing reinforced PVC profiles

Maximum automation and precision for the complete processing of the already reinforced profile

Perfect if…

- Do you want to eliminate manual steps and reduce processing times on already reinforced profiles?

- You need a machine that works on all sides of the profile, including the angled faces.

- Do you want to increase hourly productivity with just one operator?

- Small batches or inaccurate bars slow down your production process.

- Do you want to integrate digital management and teleassistance for monitoring and optimisation?

Request the technical brochure now or speak with an expert.

Maximum automation and precision for the complete processing of the already reinforced profile

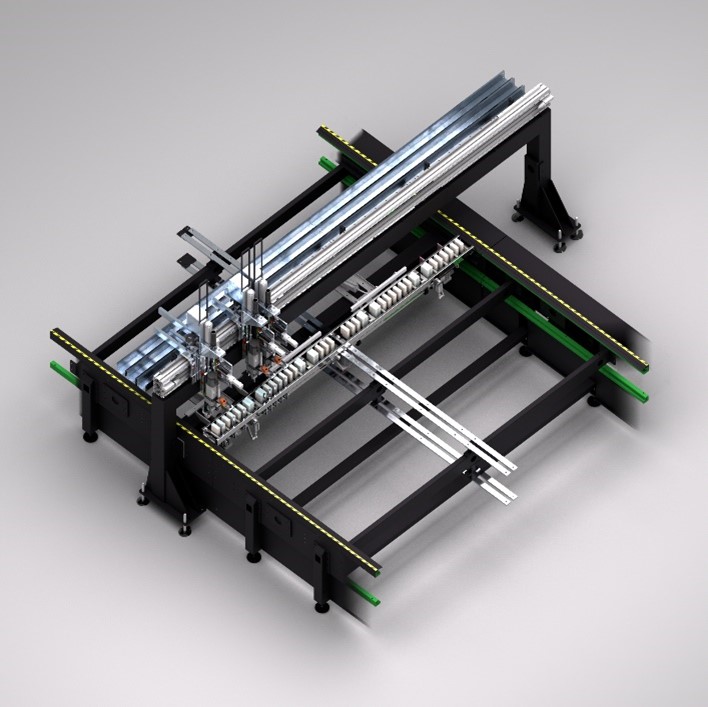

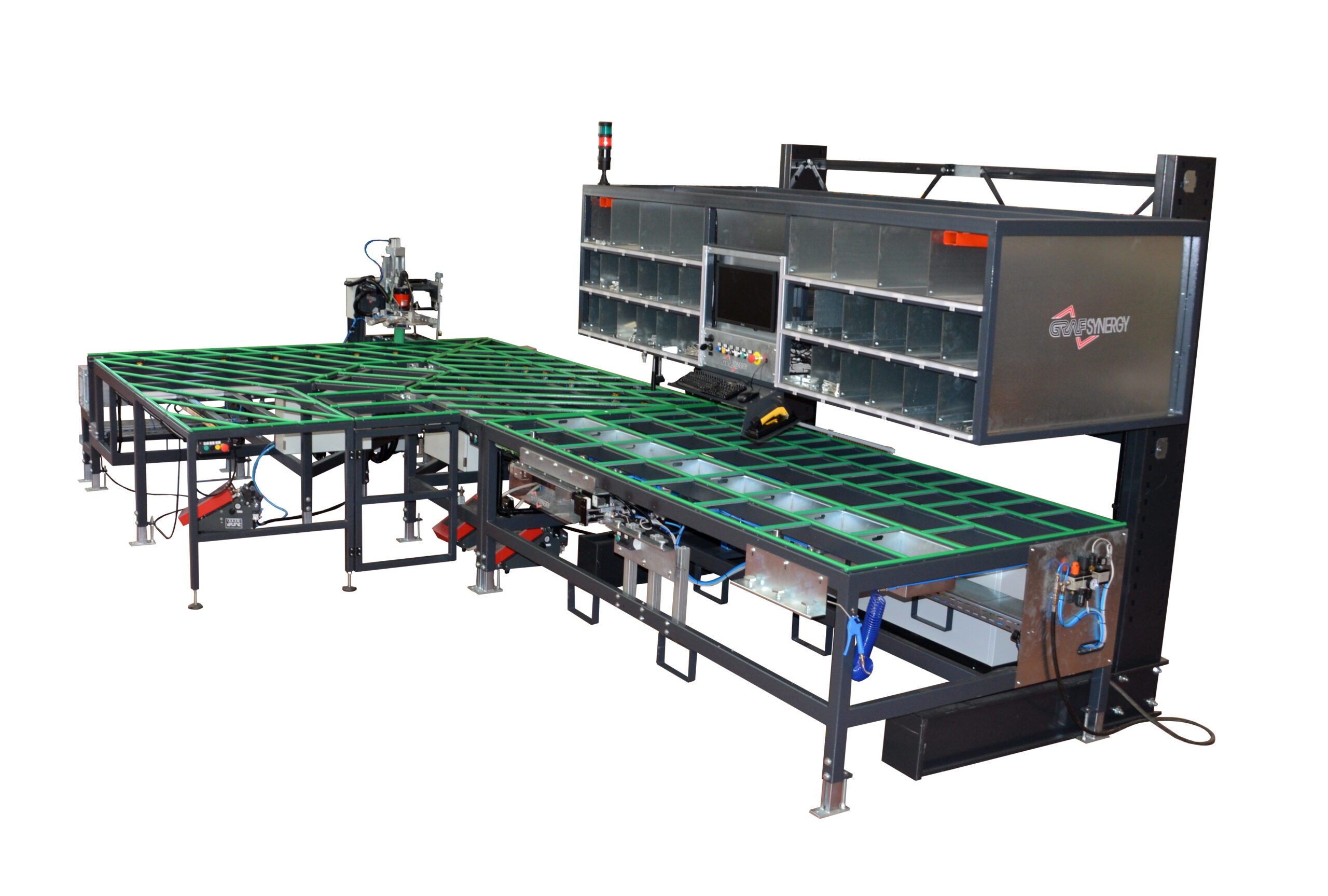

The Linear Fab 5000 is a 5-axis CNC machining centre designed to carry out all required operations on pre-cut PVC profiles with pre-inserted metal reinforcement, completely autonomously and in a single operation.

Thanks to an integrated system that includes an automated loading warehouse, a linear motor CNC gripper, and a high-speed multi-spindle module, the plant sequentially manages the picking, processing, and unloading of profiles, optimising productivity, precision, and labour utilisation.

The software interface allows for easy import of production lists, optimising the available bars and ensuring maximum accuracy even with bars that are not perfectly straight, thanks to the automatic alignment system. Ideal for high-efficiency PVC window manufacturers.

5 reasons to choose the Linear Fab 5000

- Total automation, one operator. The system manages loading, processing, and unloading with full automation: only one operator is needed to feed the bar stock.

- Maximum precision even on imperfect bars. The automatic alignment system corrects any linearity defects in the bars, ensuring perfect tolerances.

- All operations in one machine. Up to 13 high-speed spindles for drilling, slots, notches, and markings on PVC and reinforced profiles.

- Adaptable and configurable. Ability to integrate up to 11 additional spindles, screw-driving units, and special clamps for profiles up to 180 mm in height.

- Integrated software and optimised management. Importing production lists, optimising cuts, remote connection, and compatibility with Industry 4.0.

Product Details

The work module is equipped with a high-speed multi-spindle system (5 standard, expandable) that allows for all the main machining operations on PVC profiles and reinforced PVC.

Dimensions

Length: 10,500 mm

Width: 2,650 mm

Height: 2,050 mm

Weight: 3.000 Kg

Performance

Up to 180 single-pane windows in 8 hours*

*Depends on the type of profile and required processes

Operators required: 1

power supply and Consumption

Installed power: 8 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption: 150 Nl/min

Workable profiles (automatic upload)

Length: 350 – 3,500 mm

Width: 40 – 130 mm

Height: 40 – 130 mm

Supported features and processes

About PVC:

- Condensate drain holes

- Handle holes, hinge, cylinder

- Ventilation holes

- Lock picks

- Markings and feedback

On PVC + reinforcement:

- Wall mounting holes, hinges, crossbars

- Reinforcement screw (with optional unit)

- Other custom perforations available upon request.

Optional and configurations

The Linear Fab 5000 is designed to cater to productions with specific requirements. It can be equipped with:

- Reinforced Early Screw Unit: 2 opposing automatic screwdrivers with screw loading (requires 850 Nl/min)

- Additional chucks: up to 11 extras, depending on the required operations

- Special morse: for profiles up to 180 mm in height

- Radio CCD barcode reader: for automatic profile identification

- Internet Teleassistance (TCP/IP): for remote support

Technology and automation

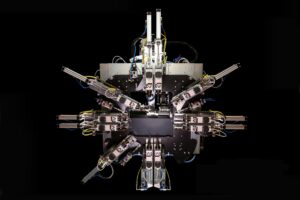

The technological heart of the machine is represented by the 5-axis CNC control, high-precision linear drives, hundredth-of-a-millimetre position reading, and intelligent software.

The machine integrates:

- Industry 4.0 Compatibility with remote connection and diagnostics.

- 3-axis CNC clamp on linear guides

- High-resolution magnetic reading for positioning

- Intuitive user interface for job and list management

Want to discover how the Linear Fab 5000 can revolutionise your production?

Request the detailed brochure now or book a demo with our GRAF Synergy experts.