LINEAR CUT 500 ALU

CNC cutting centre for aluminium profiles

Maximum productivity, perfect cutting, and complete automation in just 12 metres

Perfect for:

- Do you want to automate the cutting of aluminium profiles while reducing human intervention?

- You need high productivity across three shifts with a reliable machine.

- You work with imperfectly straight profiles and are looking for an automatic correction.

- You have little time to train the operators, and you need user-friendly software.

- Do you want to maximise the yield of the raw material through optimised cutting?

- Are you looking for an Industry 4.0-ready solution to integrate into a complete line?

Request the technical brochure now or speak with an expert.

Maximum productivity, perfect cutting, and complete automation in just 12 metres

3-axis CNC cutting centre designed to autonomously carry out the complete cutting cycle on aluminium profiles. From the feeding of raw bars to the storage of the finished piece, the LINEAR CUT 500 ALU operates seamlessly without interruptions or the need for continuous supervision, optimising schedules and reducing waste. It combines hundredth-of-a-millimetre precision, operational flexibility, and an intuitive interface, making it ideal for companies looking to enhance their cutting department with a focus on efficiency and consistent quality.

5 Reasons to Choose the LINEAR CUT 500 ALU

- Guaranteed long-term automatic precision. Thanks to the dynamic alignment system and the CNC clamp with centesimal magnetic band, every cut is accurate in relation to the actual linearity of the bar.

- Higher yield on every cut bar. The GRAF Synergy software optimises the entire production list, reducing waste and improving material efficiency.

- Simple interface, professional results. The proprietary software with guided menus makes it accessible even for less experienced users, minimising the learning time.

- Total autonomy of the work cycle. Loading, positioning, cutting, and unloading occur in sequence without the need for supervision, with continuous process monitoring.

- Ready for the evolution of your production department. Compatible with screw fastening modules, labelling systems, advanced sensors, and tailored solutions for special profiles.

Product Details

The LINEAR CUT 500 ALU allows for precise cuts on aluminium profiles, including custom angles, across multiple consecutive bars. The complete automation of the process ensures a consistent output without manual errors.

Dimensions

Length: 12,500 mm

Width: 2,200 mm

Height: 2,000 mm

Weight: 3.000 kg

power supply and consumption

Installed power: 7 kW

Power Supply: 400 V

Air consumption per cycle: 100 Nl/min

Minimum operating pressure: 7 bar

Performance

Productivity: up to 300 windows/8h (1 leaf, varying according to the profile)

Operators required: 1

workable profiles

Length: 500 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 135 mm

Supported features and processes

Main processes:

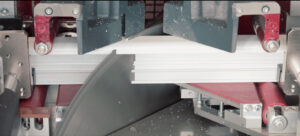

- Cutting with a Ø 500 mm blade

- Angles -45° / 90° / +45°

- Non-linear automatic correction bar

- Automatic unloading with extractor and safety photocells

Optional available

- Loader for bars from 400 to 700 mm

- Blade Ø 550 mm for profiles up to 180 mm

- Additional pressure kits for complex profiles

- Rotazione lama brushless per angoli intermedi

- Fly Optimizer per riutilizzo automatico avanzi

- Download extension and profile control sensors

- Manual labeler and chip conveyor

- Integration with ASG-E screw fastening centres

- Special configurations for sections up to 230 mm

- Preparation for PVC cutting

Each LINEAR CUT 500 ALU can be customised to perfectly meet specific production needs, thanks to a wide range of optional configurations, including:

Technology and Automation

The machine is managed by an intuitive proprietary software that allows for quick setup of operations, optimisation of sequences, and real-time monitoring. Integrated smart sensors ensure correct positioning and immediate identification of any loading errors. The CNC gripper on prismatic guides, the optional brushless blade rotation system, and the automatic piece extraction complete a technological ecosystem designed for efficiency, reliability, and Industry 4.0 integration.

Contact us to find out if the LINEAR CUT 500 ALU is the right solution for your production.