HDMV

Automatic station for hinge assembly on PVC and aluminium frames

Automate hinge assembly and boost productivity without compromising on precision and space

Perfect if you want:

- Significantly reduce hinge assembly times.

- Automate drilling, insertion, and screwing in a single cycle.

- Working with consistent precision even on already welded frames.

- Seamlessly integrate the process into an automated line.

- Save space and labour

Request the technical brochure now or speak with an expert.

Automate hinge assembly and boost productivity without compromising on accuracy and space

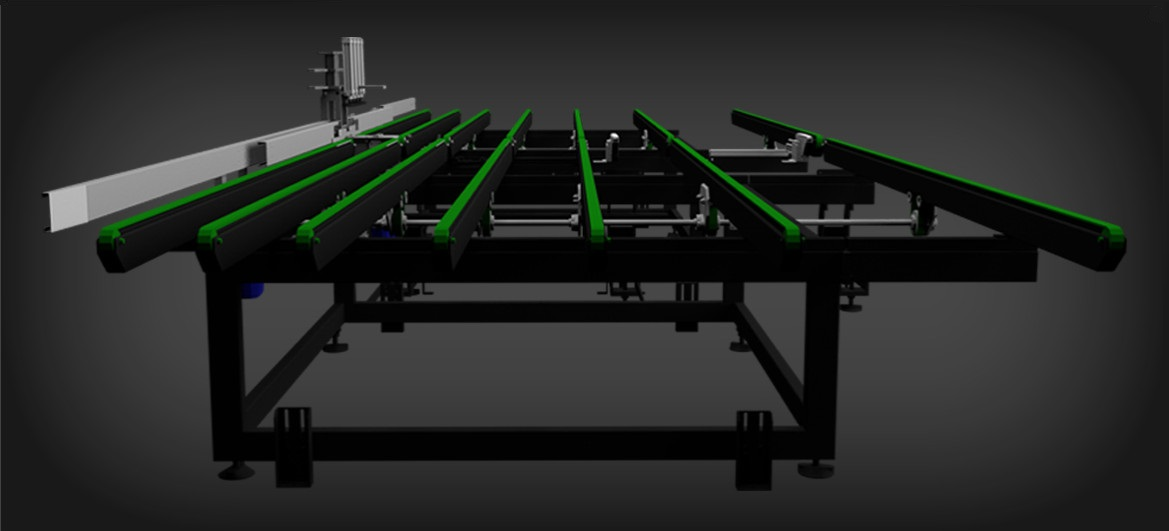

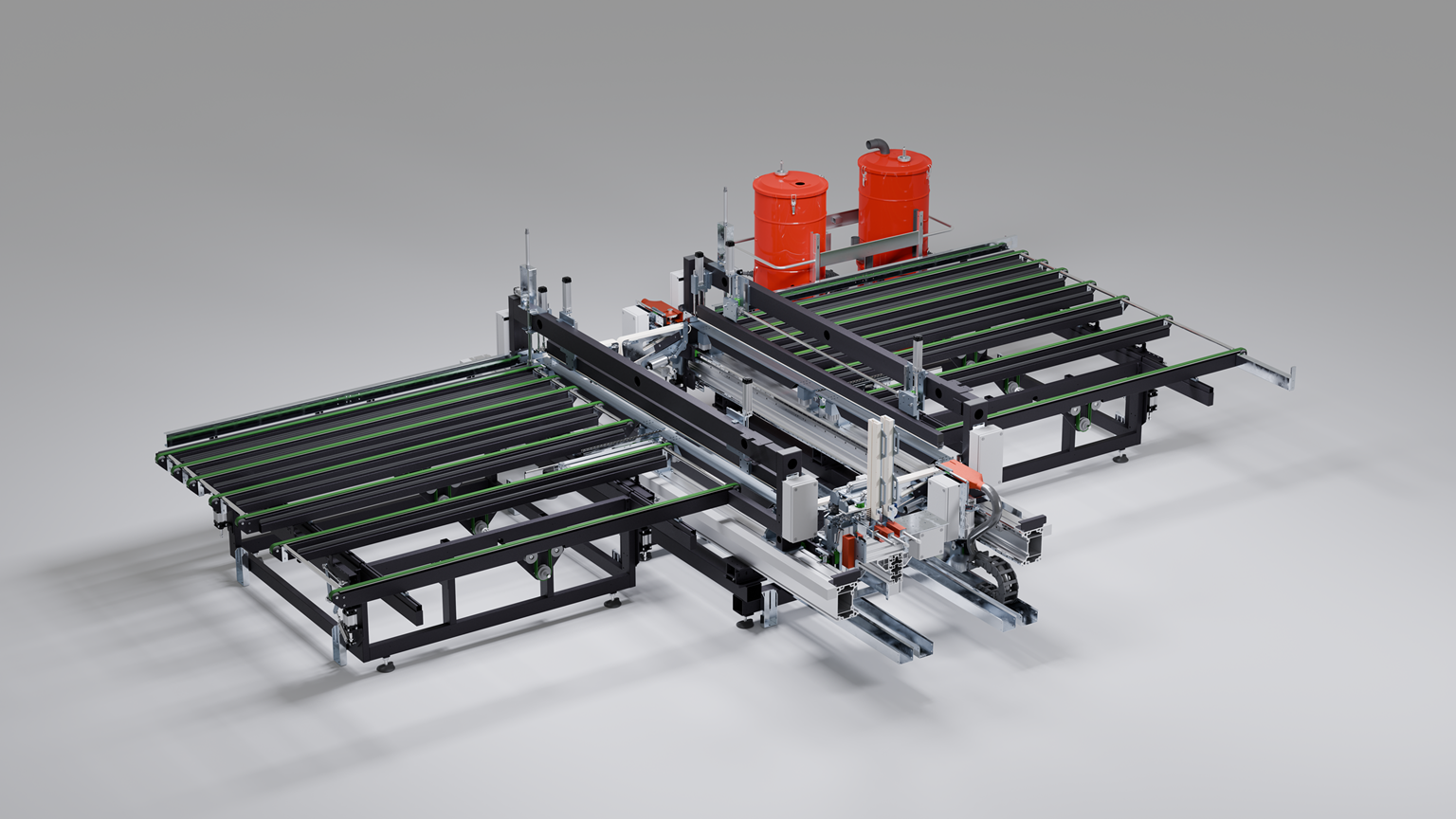

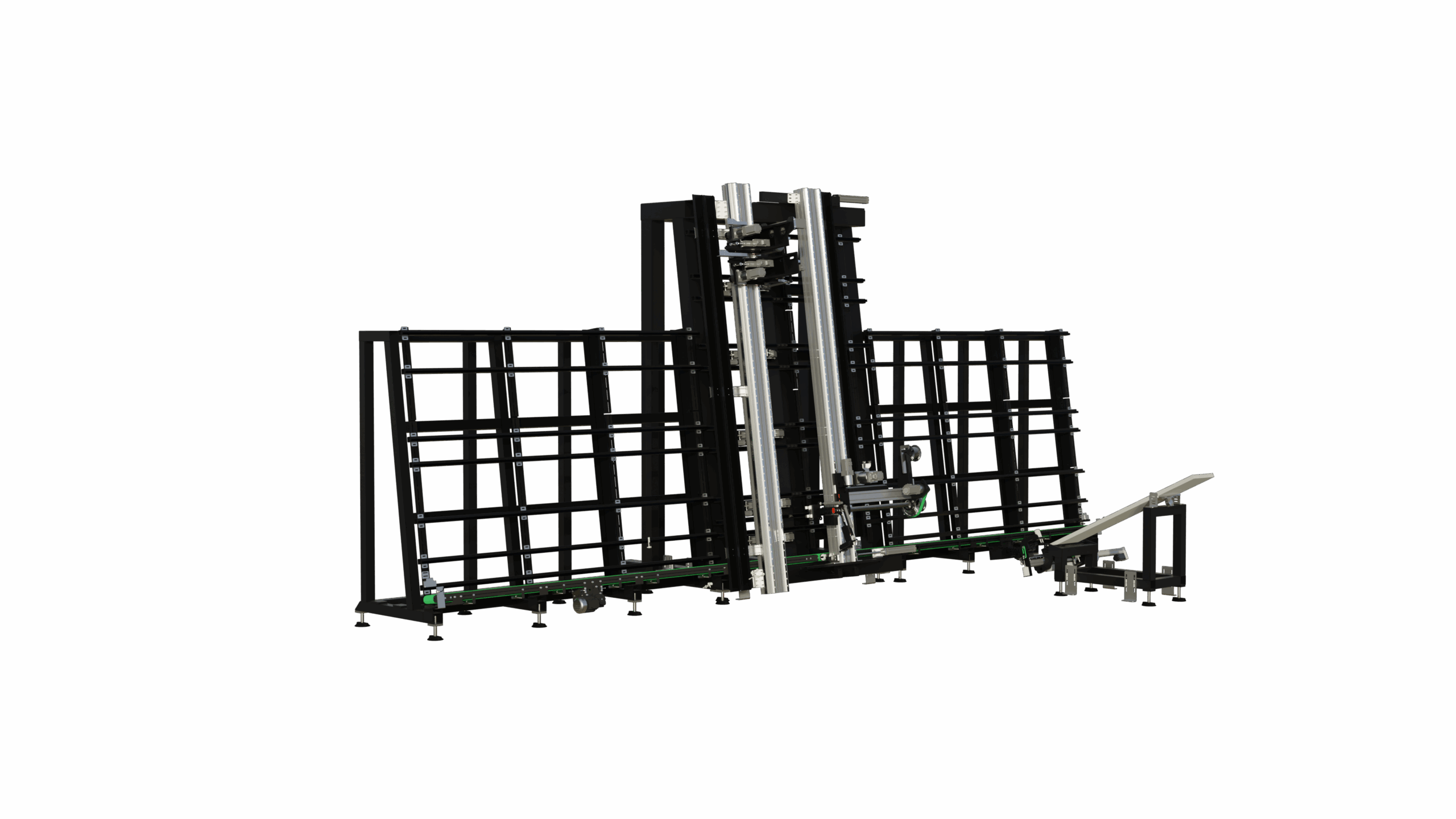

HDMV is a multi-axis CNC workstation designed to fully automate the drilling, insertion, and screwing of hinges onto PVC or aluminium frames, including intermediate posts.

Thanks to its electro-welded steel structure and a system of horizontal and vertical pneumatic clamps, it offers absolute stability and millimetric precision in every operation.

The workbench is equipped with a multi-head for simultaneous drilling, storage for hinges, automated gripping hand, and screwdrivers with automatic screw loading.

The system autonomously detects the internal width of the glazing bead groove to accurately define the position of the holes.

An ideal solution for integrating the assembly phase into a fully automated production line.

5 reasons to choose HDMV

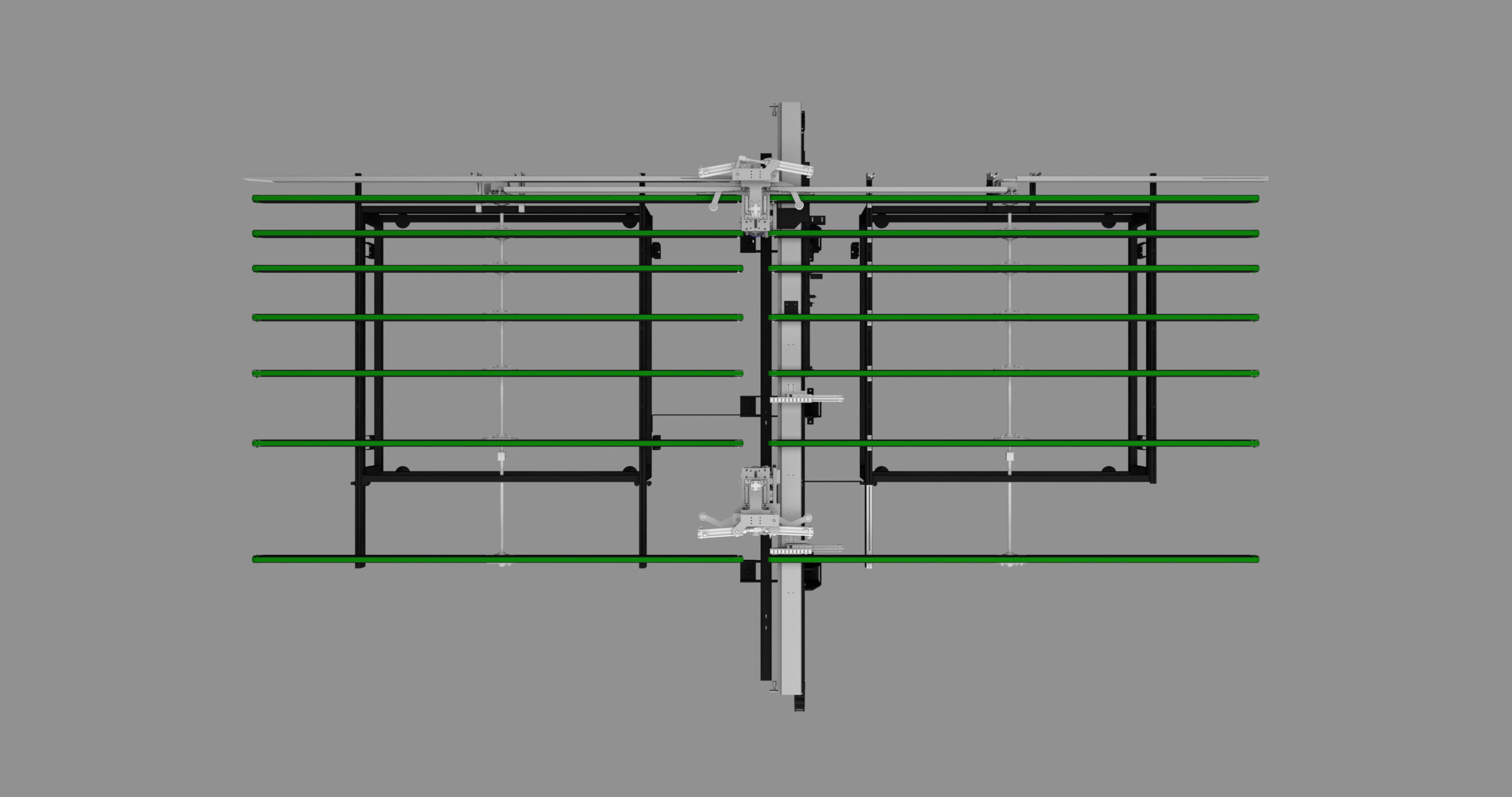

- Fully automatic assembly. It manages every stage without continuous manual intervention: positioning, drilling, insertion, and screwing.

- Accuracy ensured by active measurements. The system automatically detects the glass stop quarry and positions each hole perfectly.

- Seamless integration. It easily connects to welding machines and other workstations for a continuous production flow.

- Compact yet comprehensive. A single machine for three complex processes, featuring a space-saving design.

- Intuitive interface and quick setup. CNC configuration is user-friendly even for operators with little experience.

Product Details

HDMV is a multi-axis CNC workstation designed to fully automate the drilling, insertion, and screwing of hinges onto PVC or aluminium frames, including intermediate posts.

Machine dimensions

Length: 8,200 mm

Width: 4,700 mm

Height: 3,000 mm

Weight: 3.500 Kg

Operational performance

Operators required: 1 (for loading hinges and screws only)

(*time varies depending on frame type and configuration)

power supply and Consumption

Installed power: 10 kW

Power Supply: 400 V

Minimum exercise pressure: 8 bar

Air consumption: 100 Nl/min

Workable profiles

Usable frame sizes: up to 3,200 x 2,800 mm (depending on the welder’s capacity)

Supported features and processes

HDMV automatically performs all operations of:

- Drilling frames and intermediate supports

- Fitting and screwing in hinges

- Automatic detection of the glass stop quarry

- Screwing with automatic depth adjustment

- Automatic reset sequence at the end of the cycle

Optional and configurations

Available upon request for maximum adaptability:

- Loading on the right or left side

- Oversized mat for ‘Dormat Large’ profiles

- Doppie testine per diverse marche ferramenta

90° rotating heads for drilling transom windows.

Technology and automation

HDMV integrates a CNC system with advanced sensors and automation. Every operation is traceable and can be managed remotely. The machine is designed for integration with management systems and Industry 4.0 environments, enabling predictive maintenance.

Do you want to increase the efficiency of your assembly department?

Request the detailed brochure now or book a personalised demo with one of our experts.