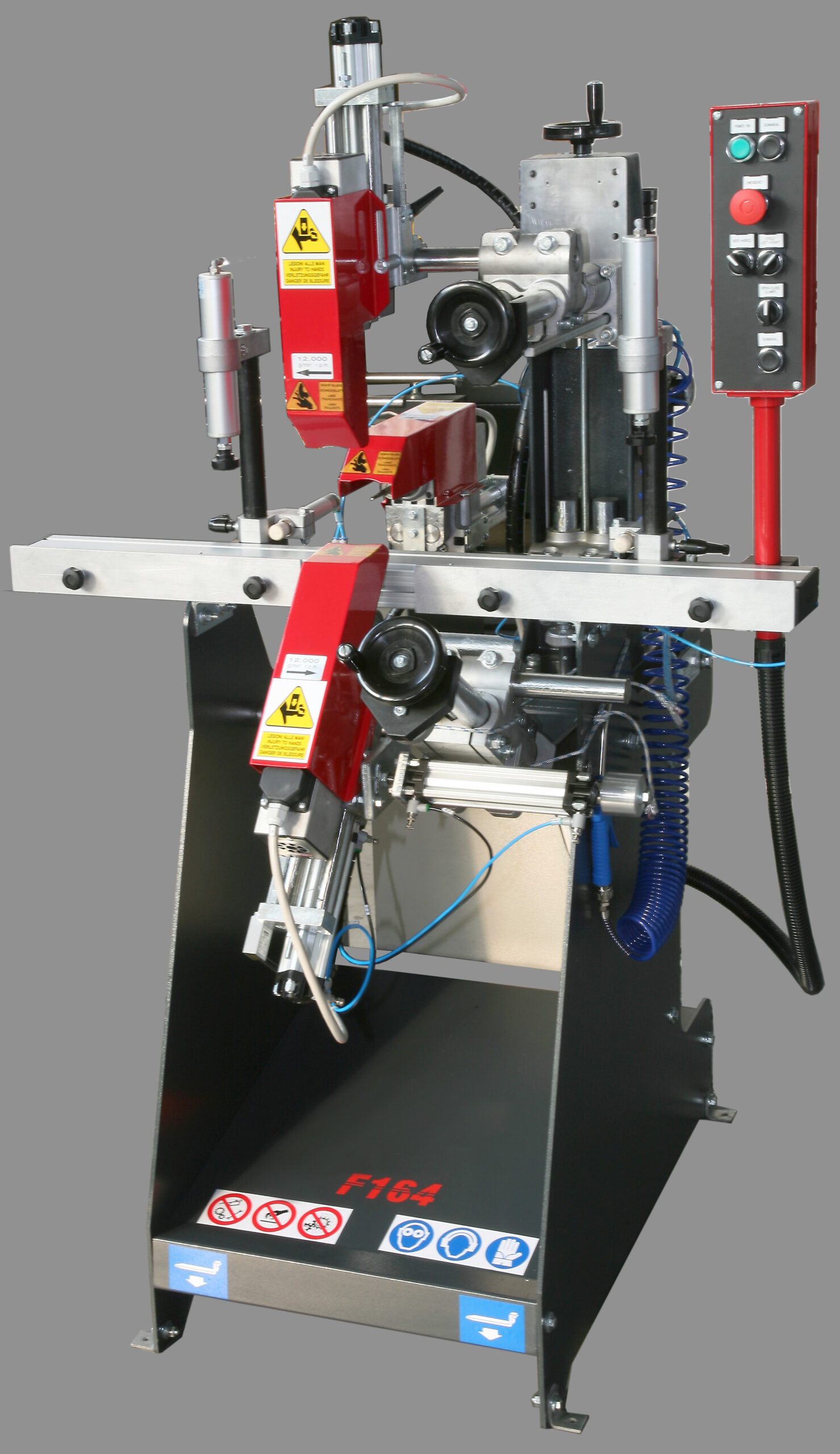

GC3-SL

End milling machine for PVC/Aluminium profile seals

Maximum precision in frame door closures. Say goodbye to forced fittings.

Perfect if you want…

- Eliminate the constraints caused by the curb under the seal.

- Achieve precise and flawless angles in your fixtures.

- Work on profiles with a central seal (triple sealing) as well.

- Reduce downtime before welding

- Automate the preparation of the profile, even in small batches.

- Operate safely and easily, even with inexperienced staff.

Request the technical brochure now or speak with an expert.

Maximum precision in door frame closures. Say goodbye to forced fittings.

The GC3-SL is the milling machine designed to address one of the most common and insidious problems in the welding of profiles for fixtures: the accumulation of molten material beneath the seal. If left uncorrected, this defect leads to forcing and difficulties in fitting the glass, compromising the quality of the finished frame.

The GC3-SL allows for the quick and precise removal of excess material, both internal and external, ensuring clean and perfect surfaces for subsequent welding. Ideal for companies working with PVC profiles, with or without a central gasket, it guarantees a flawless leaf-to-frame closure.

The simultaneous processing of two pieces, millimetric mechanical adjustments, and maintenance-free high-frequency motors make this machine an essential tool for those seeking efficiency, precision, and zero rework.

5 reasons to choose GC3-SL

- Say goodbye to glass installation issues. Prevent the buildup of material under the seal that hardens and hinders the insertion of the glass.

- Perfect door closure on the frame. The precise milling ensures the correct fitting of the profiles, eliminating any gaps or misalignments.

- Maximum versatility. Suitable for profiles with a central seal, ensuring optimal sealing in every configuration.

- Zero maintenance for engines. High-frequency engines designed to operate without periodic servicing.

- Fast and repeatable processing. Precise mechanical adjustments and manual selectors for a quick and secure setup on profiles of various shapes.

Product Details

The GC3-SL is designed to ensure the precise removal of excess material at the ends of profiles, preventing distortions and issues during the welding process.

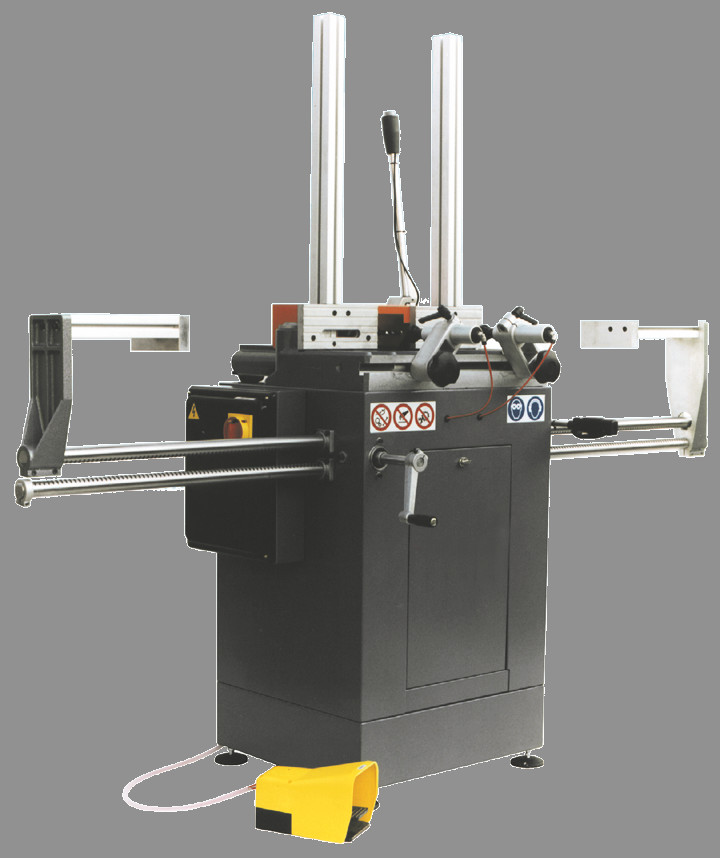

Machine dimensions

Length: 1,300 mm

Width: 1,300 mm

Height: 1,100 mm

Weight: 235 kg

Performance

Operations: manual

Operators required: 1

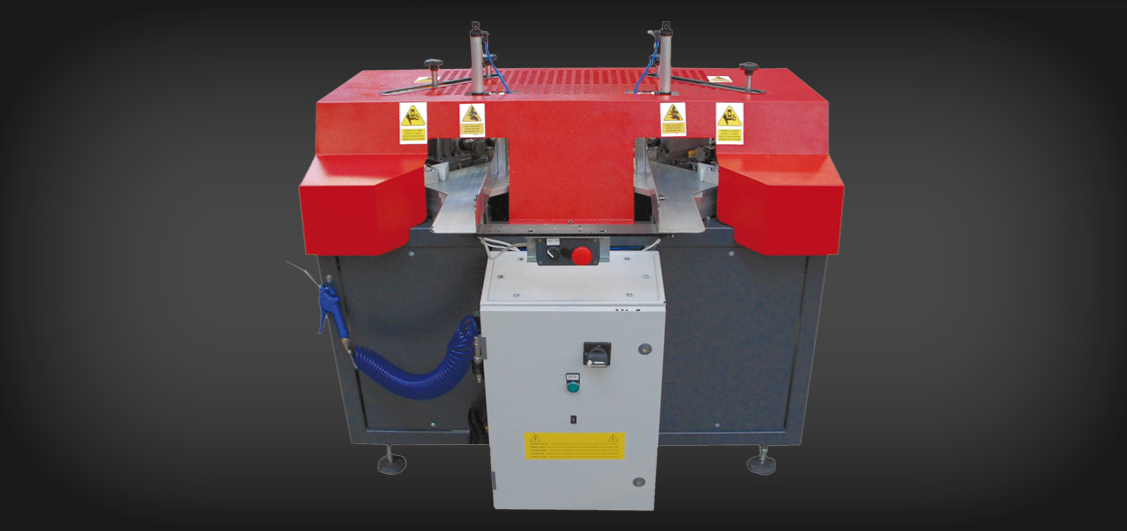

Working cycle: simultaneous processing of 2 pieces

power supply and consumption

Installed power: 1.5 kW

Power Supply Voltage: 230 V – Single Phase

Air consumption: 100 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Profile width: from 40 to 130 mm

Profile height: from 40 to 180 mm

Supported features and processes

The two adjustable milling groups allow for both the internal and external sealing to be processed in a single cycle, reducing time and ensuring perfect repeatability.

Main processes:

- Milling of the internal and external gasket

- Preparation of the profile end for welding

- Simultaneous processing of two pieces

Optional and available variants

The car is offered in a complete version, also compatible with central seal profiles.

The GC-SL variant is available upon request, specifically designed for profiles without a central seal, for those seeking a targeted and simplified solution.

No additional options or accessories are available.

Do you want to eliminate rework on edges and improve the quality of your fixtures?

Request the complete brochure or a personalised quote for your production now. The GRAF Synergy team is at your disposal for a no-obligation consultation.