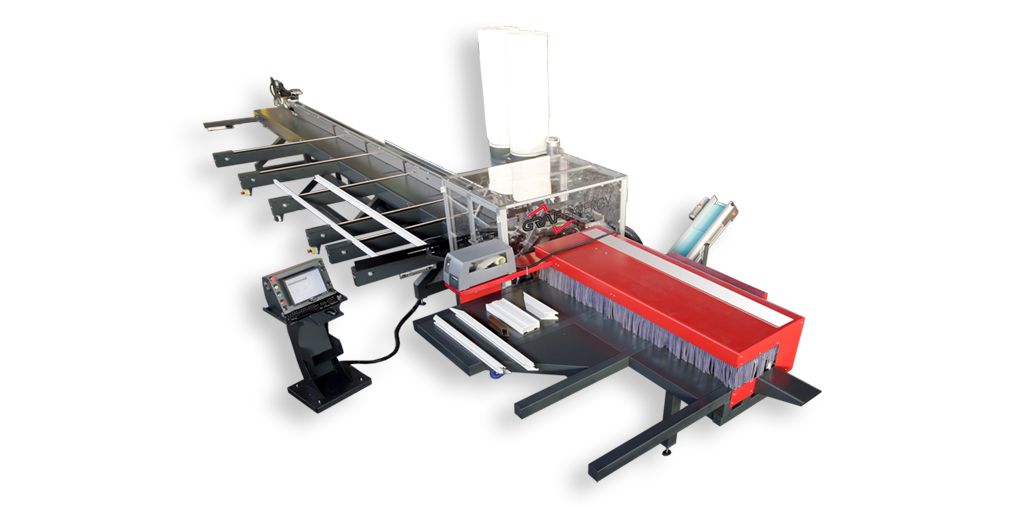

GBA 200

Automatic cutting center for PVC glazing beads

Maximum precision and automated productivity: the ultimate solution for cutting PVC glazing beads

Perfect for:

- Workshops producing PVC windows and doors looking for a system dedicated to glazing beads

- Those who want to standardize cutting quality regardless of profile shape

- Companies aiming to minimize manual labor

- Medium-to-large production facilities requiring full automation

- Those seeking perfect angle alignment during assembly

Request the technical brochure now or speak with an expert

Automatic and intelligent cutting with consistent precision

The GBA 200 is a controlled-axis cutting center designed for the automatic processing of PVC glazing beads.

Built with a steel and aluminum structure, it combines robustness and reliability with fully automated management of the production process.

The system features a mobile carriage with a fixed 45° tilt, two main Ø 200 mm blades, and two secondary Ø 98 mm blades, ideal for precisely finishing the ends of the fixing foot.

Operator involvement is limited to loading the bars and unloading the finished pieces.

5 reasons to choose the GBA 200

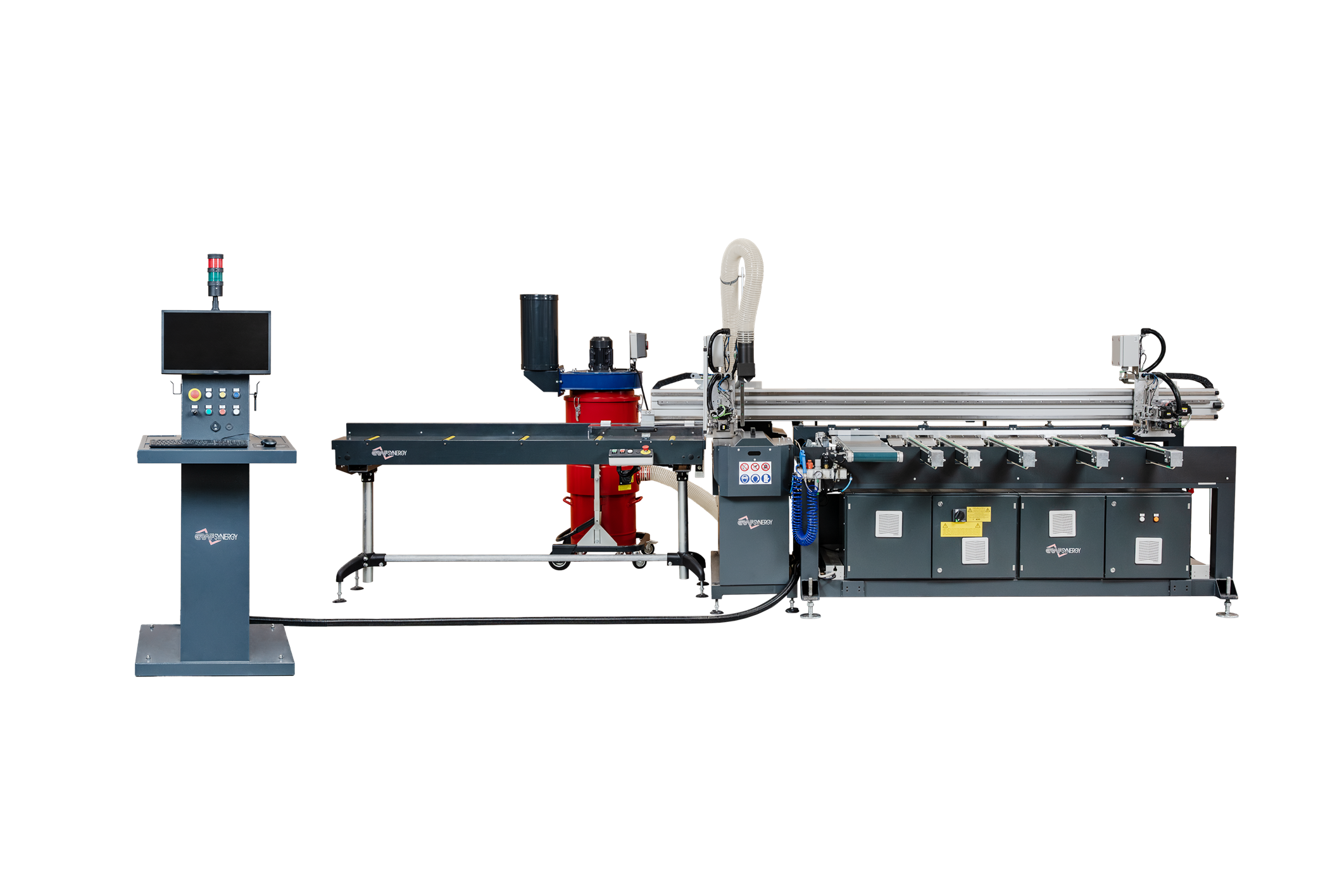

- Total cutting automation. The entire cycle is managed by software with numerically controlled axes.

- Clean and repeatable cuts. The high blade rotation speed ensures consistent quality even on complex profiles.

- High flexibility without changing counter-profiles. New glazing beads can be added directly via software.

- Assembly-simulated precision. The gripping system replicates actual installation for perfect corner alignment.

- Always clean working area. Equipped with a powerful extraction system for chips and waste.

Product Details

The GBA 200 is a controlled-axis cutting center designed for the automatic processing of PVC glazing beads.

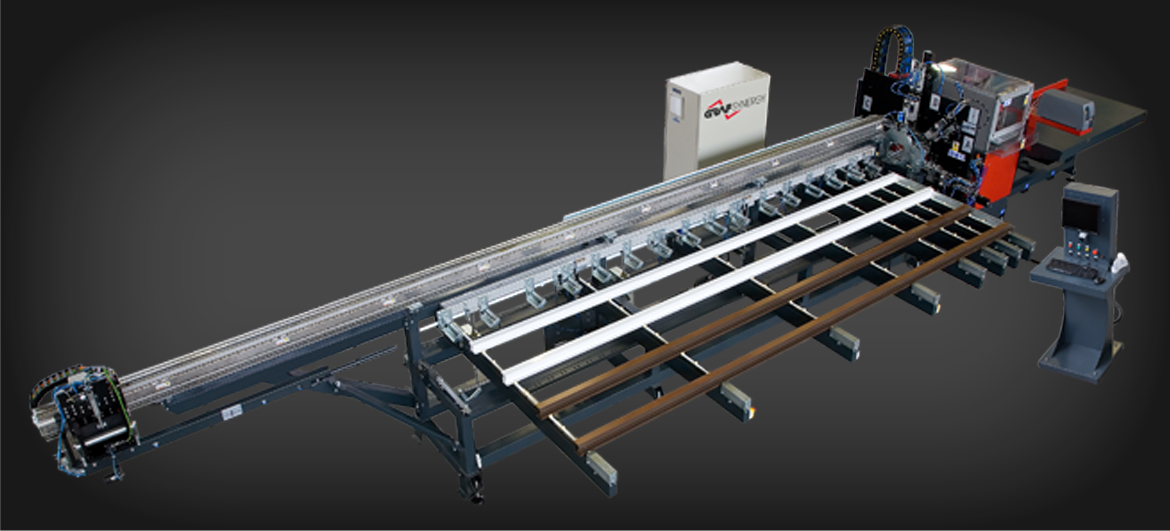

Machine dimensions

Length: 10,000 mm

Width: 1,500 mm

Height: 1,300 mm

Weight: 800 kg

Operating performance

Operation: fully automatic

Operators required: only for loading and unloading

Power supply and consumption

Installed power: 2,5 kW (+ 1,5 kW aspiratore)

Voltage: 400 V trifase

Minimum pressure: 7 bar

Air consumption: 100 Nl/min

Profiles that can be processed

Height: 10 ÷ 35 mm

Width: 18 ÷ 45 mm

Supported operations

Simultaneous cutting of 2 glazing beads of the same length

Trimming of feet with dedicated secondary blades

Longitudinal anti-bending tensioning

Glass-mount simulation for angular precision

Automatic setting of optimal parameters via GRAF Synergy software

Available options

- 90° blades for special cuts

- Automatic loading of glazing bead bars to maximize productivity

Technology and automation

The intuitive user interface allows quick profile selection and independent entry of new models. Compatible with Industry 4.0 standards, the GBA 200 is ready for integration into automated production lines and smart factory environments.

Do you want to automate glazing bead cutting with precision and speed?

Request a demo or a personalized quote now.