FAZ III

Automatic Bench for Fitting Hardware on PVC Doors

Maximise efficiency in hardware assembly: automate, accelerate, optimise.

Perfect if…

- Do you want to automate the fitting of hardware on PVC doors, reducing errors and rework?

- Are you looking for a machine that maintains high productivity even with just one operator?

- You need to integrate the bench into an existing automated line.

- You need to work with a wider range of hardware and screws, with smart management.

- You need versatility in formats (from 350×500 mm to 2700×1200 mm).

- Do you want to reduce the screwing time to less than 65 seconds per door leaf?

Request the technical brochure now or speak with an expert.

Maximise efficiency in hardware assembly: automate, accelerate, optimise.

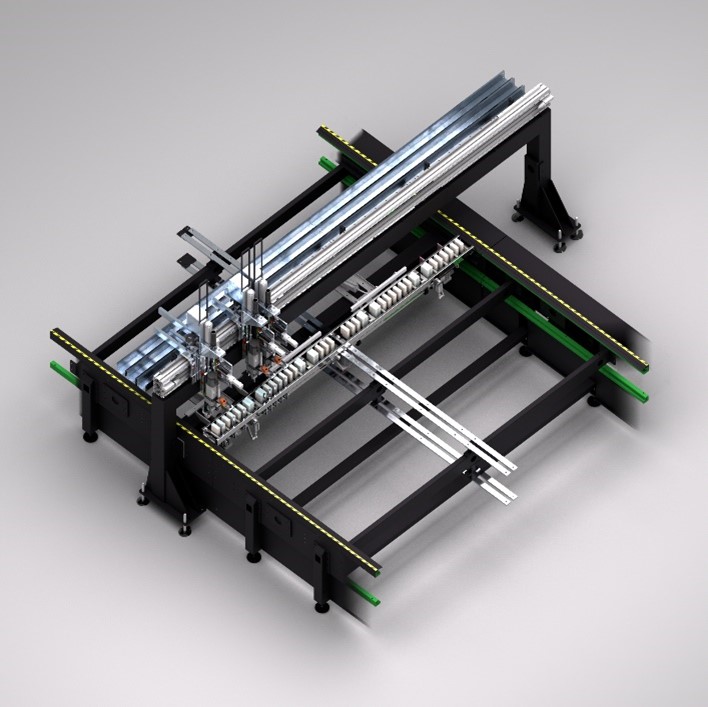

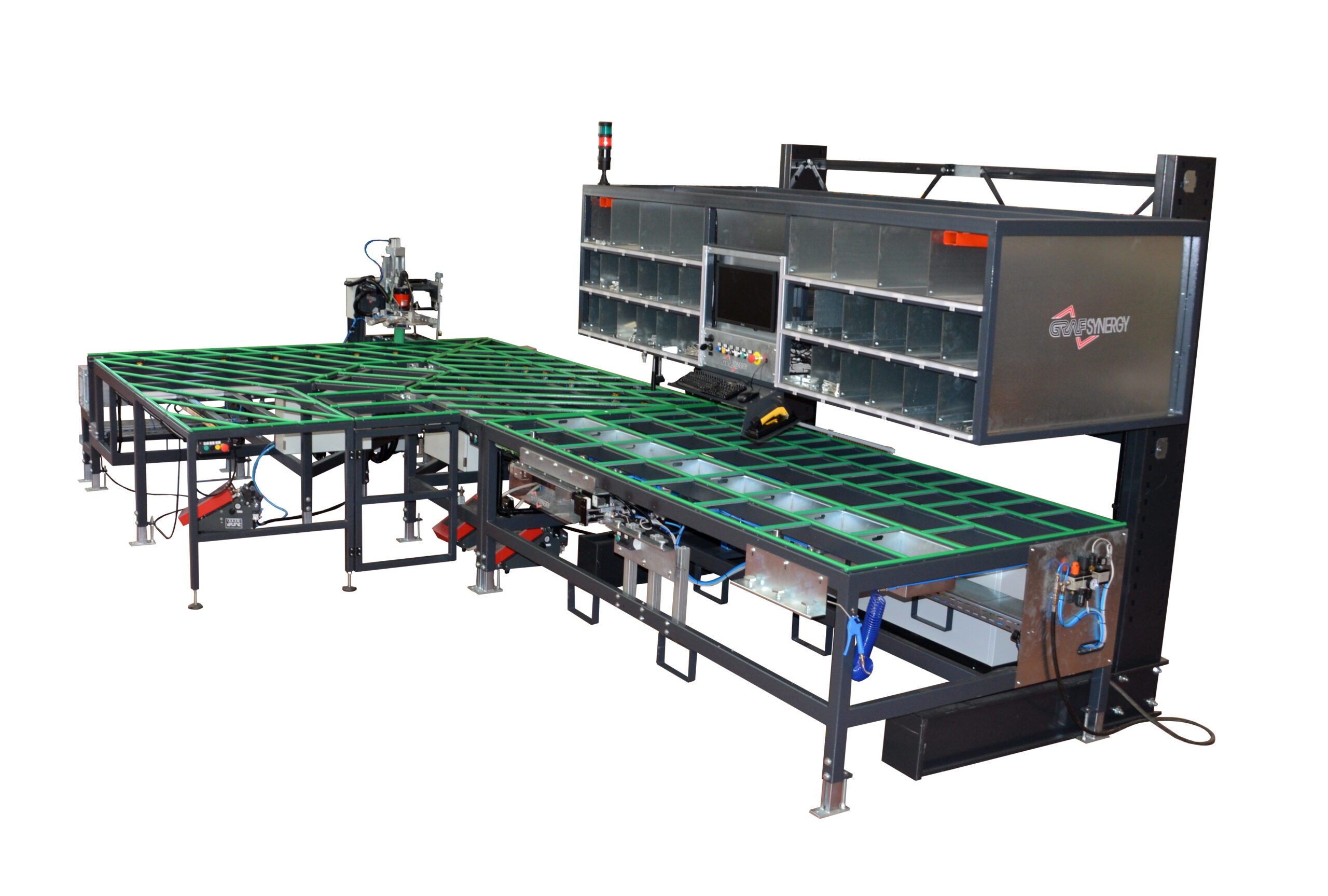

The FAZ III is a CNC bench designed for the automatic assembly and screwing of hardware onto PVC doors, engineered to seamlessly integrate into an automated production line.

Equipped with one or two preparation stations and a high-speed screw driving portal, it drastically reduces cycle times and the required labour.

Thanks to its intelligent design and automatic management of screws and drilling depths, it allows you to complete a door in just 60 seconds, ensuring consistent precision, continuous production, and versatility in sizes.

Ideal for companies aiming for high-volume PVC window production without compromising on quality or increasing operational costs.

5 reasons to choose FAZ III

- Continuous Production. Thanks to the overlapping cycle logic, while one fitting is being screwed in, the next door can already be pre-assembled, optimising the flow.

- Integration with Automated Lines. Compatible with automated packing and transport systems, ensuring seamless integration into existing layouts.

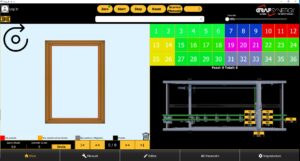

- Intuitive interface. The software guides the operator step-by-step, even without experience, indicating the position and type of tool to be mounted.

- Extraordinary cycle speed. A panel completes every 60-65 seconds, with automatic management of screw type and driving depth.

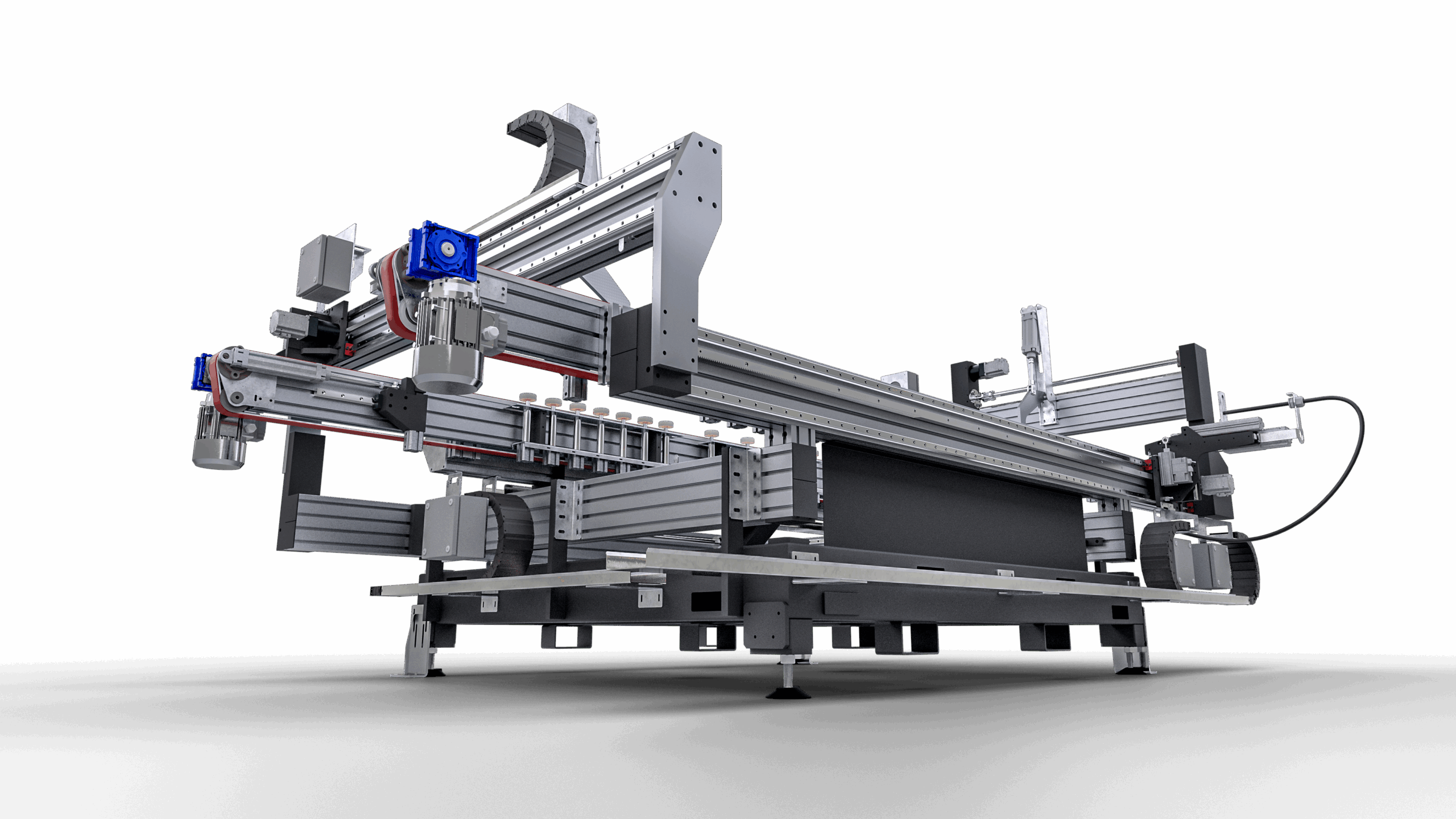

- Versatility and configurability. Modular with 2 or 3 stations, dedicated options for special tools, handling profiles from 50 to 130 mm in width.

Product Details

The FAZ III workstation automates the entire assembly cycle for hardware: from preparation to fastening. Its modular station architecture allows for a logical separation between phases, enhancing productivity and operational safety.

Overall dimensions (bench + screw portal)

Length: 7,950 mm

Width: 2,480 mm

Height: 2,510 mm

Weight: 7,130 Kg

Additional bench (optional)

Length: 3,000 mm

Width: 2,000 mm

Height: 2,510 mm

Weight: 1.580 Kg

Performance

Cycle time: up to 65 sec/phase*

Operators required: 1-2

*Indicative values: depend on profile, size, and hardware.

power supply and Consumption

Installed power: 8 kW

Power Supply: 400 V

Minimum pressure: 7 bar

Air consumption: 500 Nl/min

Workable profiles

Maximum door size: 2700 x 1200 mm

Minimum door size: 350 x 500 mm

Profile width: from 50 to 130 mm

Supported features and processes

FAZ III is available in a customised version to suit divers.

Main Processes

- Hardware positioning

- Tool cutting (to size)

- Automatic screwing on 4 sides

Operating Procedures

- Pre-assembly of the “recessed edge” door

- High-speed double screw fastening on a mobile portal

Optional and configurations

The FAZ III is available in a customised version to meet various production needs. Optional configurations include:

- Tool programming based on the type of window

- Version with just one High Speed screwdriver for tight spaces

- Support for special screws or screws of different lengths

- Exit with horizontal station or automatic verticalisation

Each element is designed to provide maximum flexibility and promote the scalability of the system.

Technology and automation

Equipped with an advanced CNC logic and a simplified graphical interface, the FAZ III bench automatically recognises the type of hardware, selects the correct screw, and precisely adjusts the depth of fastening.

Software and Controls

- Automatic screw type selection

- Electronic depth control regulator

- Guided user interface for operators

Integration and Industry 4.0

- Compatible with custom layouts and business management systems.

- Preparation for Industry 4.0 for interconnection, monitoring, and remote assistance.

Download the complete brochure now or request a personalised quote for FAZ III.