FAZ II

Automated hardware assembly centre for PVC fittings

Increase productivity and reduce labour in hardware assembly

Perfect if you wish:

- Automate the assembly of hardware to reduce reliance on the operator.

- Increase the number of processed panels per shift without compromising on quality.

- Standardise the process by reducing manual errors and rework.

- Optimise workshop space with a compact and integrable machine.

- Connect the workstation to an existing production line with automated systems.

Request the technical brochure now or speak to an expert.

Increase productivity and reduce labour in hardware assembly

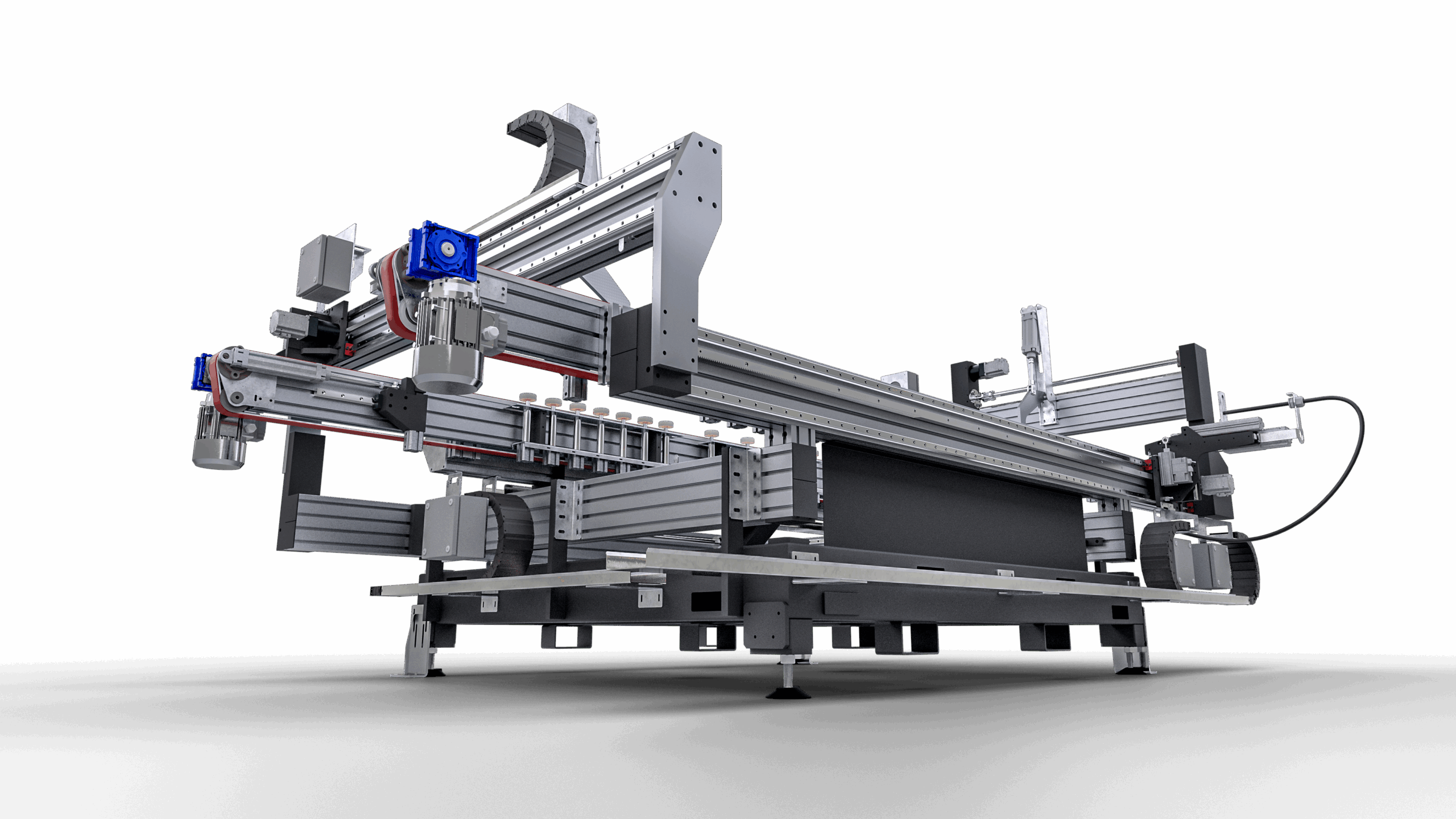

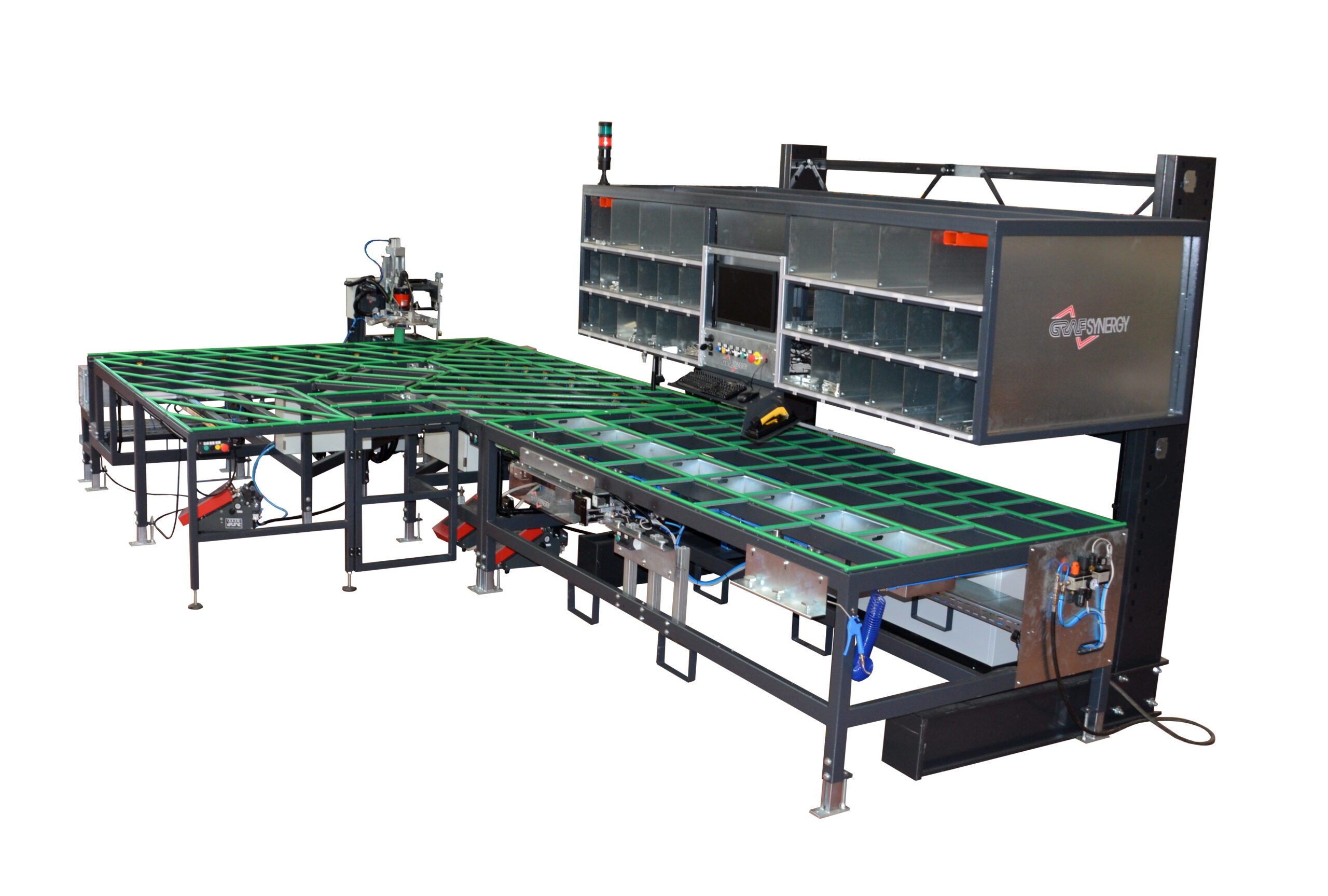

The FAZ II is a compact and automated workstation designed by GRAF Synergy to speed up and standardise the assembly of hardware on PVC doors. With its dual station – preparation bench and screwdriving table – it allows for the assembly of up to 240 frames per shift, with just one operator.

While the first frame is being screwed in, the next one can already be pre-assembled, ensuring a continuous and uninterrupted production flow.

Equipped with intelligent software, automatic screw selection, and high-speed devices, the FAZ II easily integrates into existing production lines, enhancing efficiency and reducing setup times.

5 reasons to choose FAZ II

- Continuous Production. Pre-assembly and screwing occur simultaneously: the operator is never left waiting.

- Integration with existing lines. Thanks to automated transport systems, the FAZ II seamlessly fits into continuous production flows.

- User-friendly interface. The software offers step-by-step guidance, even for inexperienced users, showing which compartment to retrieve each item from.

- Extensive library of tools and profiles. Integrated database for managing assembly programs based on window types.

- Compact and Organised Island. The integrated storage with 32 compartments ensures order and quick access to tools.

Product Details

The FAZ II allows for the automation of all critical phases of hardware assembly on PVC doors.

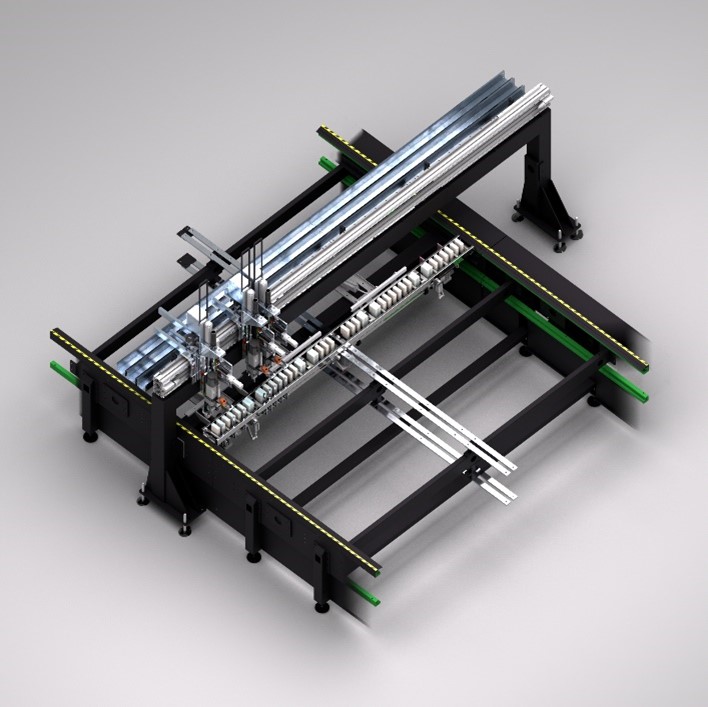

Dimensions

Length: 6,750 mm

Width: 3,760 mm

Height: 2,500 mm

Weight: 1,800 kg

Performance

Productivity: up to 240 square metres/8h*

Operators required: 1

(*depending on the type of profile and hardware)

power supply and Consumption

Installed power: 4.5 kW

Voltage: 400 V

Air consumption: 800 Nl/min

Operating pressure: ≥ 7 bar

Profiles and workable dimensions

Maximum door size: 2500 x 1200 mm

Minimum door size: 350 x 500 mm

Profile width: from 50 to 130 mm

Supported features and processes

- Cutting and positioning of tools on the preparation bench, with a visual indication of the compartment from which to take each item.

- High-speed screwing, with 2 screwdrivers featuring automatic screw selection and depth adjustment.

- Automatic door rotation at 180° to allow processing on both sides

The system enables consistent, standardised production and minimises the margin for human error.

Optional features and available configurations

The FAZ II assembly centre is configurable to meet specific production needs. Among the available options are:

- Variant for the use of non-standard screws

- Vertical lift shuttle to enhance internal logistics

- Automatic discharge table for end of line

- Dedicated programming for specific types of windows

Each option allows for further enhancement of operational efficiency and customization of the production flow.

Technology and automation

The FAZ II is operated by dedicated software featuring an intuitive graphical interface, designed to simplify daily tasks and minimise errors. Among its technological features:

- Intelligent software with a tools/equipment database

- Automatic screw depth adjustment

- Automatic screw type selection based on the programme in use

- High-speed devices to optimise cycle times

The machine is designed for integration into Industry 4.0 lines, with the capability for remote control and management interconnection.

Do you want to improve the productivity of your hardware line? Contact us for a demo, a quote, or to receive the detailed technical brochure.