FAB CUT V

CNC cutting and processing centre for special PVC fittings

Complete Automation for Special Productions: extreme cuts, high-precision machining, maximum efficiency

Perfect if:

- Produce special fixtures with complex angles and custom cuts.

- Do you want to fully automate bar management?

- Do you often work with warped profiles and are looking for a system that can automatically correct them?

- You need high productivity with just one operator.

- Are you looking for a system ready for Industry 4.0 that can be integrated with your management software?

- Do you want a customisable solution tailored to your needs, even for aluminium profiles?

Request the technical brochure now or speak with an expert.

Complete Automation for Special Productions: extreme cuts, high-precision processing, maximum efficiency

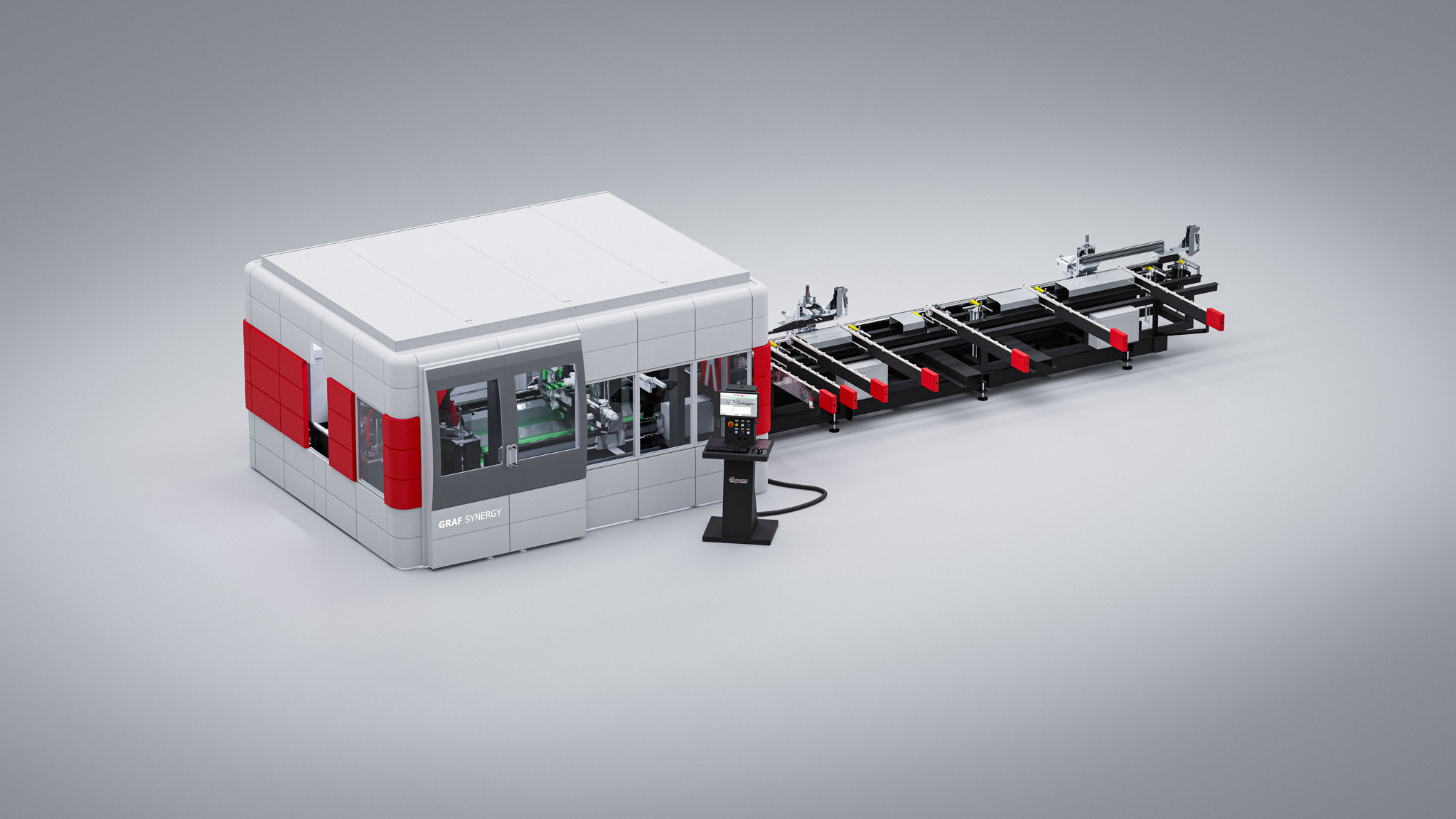

The FAB CUT V is a 4-axis CNC cutting and machining centre designed to automate production in the Special Productions department. With a fully automated system and the integration of advanced technologies, it combines the versatility of angular cutting with the efficiency of multiple machining operations on PVC profiles.

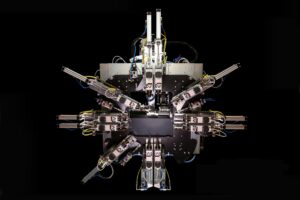

The machine consists of an automatic loading magazine (capacity of up to 10 bars), a CNC gripper with 2 axes controlled on prismatic guides with a linear motor and magnetic strip, and a configurable working module with 6 or 12 High Speed spindles. The cutting module integrates a Ø550 mm blade with an upward movement, brushless rotation, and centesimal reading for angles ranging from -22.5° to +22.5°.

An automatic alignment system straightens profiles that are not perfectly straight, ensuring maximum precision. The integrated software autonomously manages the cutting lists, optimising the bars used. The operator is limited to loading and unloading the pieces.

5 Reasons to Choose FAB CUT V

- Designed to automate the Special Productions department. it optimises the most complex processes with reliability and consistent precision over time.

- Extreme and intermediate cuts with maximum precision. Cutting module featuring a Ø550 mm blade, brushless motorised rotation, and magnetic band reading: sharp angles ranging from -22.5° to +22.5°.

- Automatic alignment of rebar. An intelligent system straightens bent bars to ensure millimetre-precise processing.

- Integrated list management software that automatically imports and optimises production lists, while keeping track of operations on a daily, weekly, monthly, and annual basis.

- Modularity and scalability. Configurable with up to 12 High Speed spindles, offering a wide range of options and connection to 1 or 2 ASG-E Centres.

Product Details

The FAB CUT V performs all the essential operations for PVC profiles in a single station, thanks to its work module equipped with 6 High Speed spindles (expandable to 12).

Dimensions

Length: 15,520 mm

Width: 3,400 mm

Height: 2,800 mm

Weight: 3.600 kg

Performance

Cycle time: Up to 150 frames/8h* (depending on profiles and processes)

Operators required: 1

power supply and Consumption

Installed power: 14 kW

Power Supply: 400 V

Air consumption: 180 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Length: 500 – 6,500 mm

Profile width: 40 – 130 mm

Height: 40 – 180 mm

Supported features and processes

- Condensate drain holes

- Handle holes, hinge, cylinder

- Lock picking

- Feedback marking

- Ventilation holes

- Special processing upon request

The cutting module, featuring a Ø550 mm blade, allows for angular cuts ranging from -22.5° to +22.5°, even on profiles with seals, ensuring clean and precise cuts over time.

Optional features and custom configurations

The FAB CUT V is a flexible platform that can be configured to meet specific production needs.

- 12 Spindle High Speed Extension

- Motorised bevel for cuts from -15° to +15°

- Fly Optimizer for the automatic reuse of leftover bars

- Option ‘Recover’ for re-entering incorrect items

- STATS software for analysing production cycles

- Discharge table with outlet on the opposite side of the loading area.

- Tool breakage sensors

- Vacuum cleaner with 2 bags, chip conveyors (1,000/2,000 mm)

- Manual or automatic labeler

- Custom soundproof booth

- Provision for automatic connection to 1 or 2 ASG-E Centres

- Special setup for aluminium profile processing

Advanced technology and automation

The FAB CUT V centre integrates the most advanced technologies for control and traceability.

- CNC clamp with 2 controlled axes, featuring a linear motor and prismatic guide.

- Reading position on the centesimal magnetic band

- Software interface for importing and optimising list management

- Comprehensive monitoring: daily, weekly, monthly, and annual activities.

- Compatibility with business management systems

- Fully ready for Industry 4.0