FAB CUT PLASMA

Cutting and processing centre for metal reinforcements

Combined plasma + blade technology for enhanced productivity

Perfect for:

- Production departments working with metal reinforcements

- Workshops aiming to automate all cutting and processing operations

- Companies looking to synchronize metal and PVC production

- Operations seeking reduced cycle times and increased efficiency

- High-volume productions with demanding versatility requirements

Request the technical brochure now or speak with an expert.

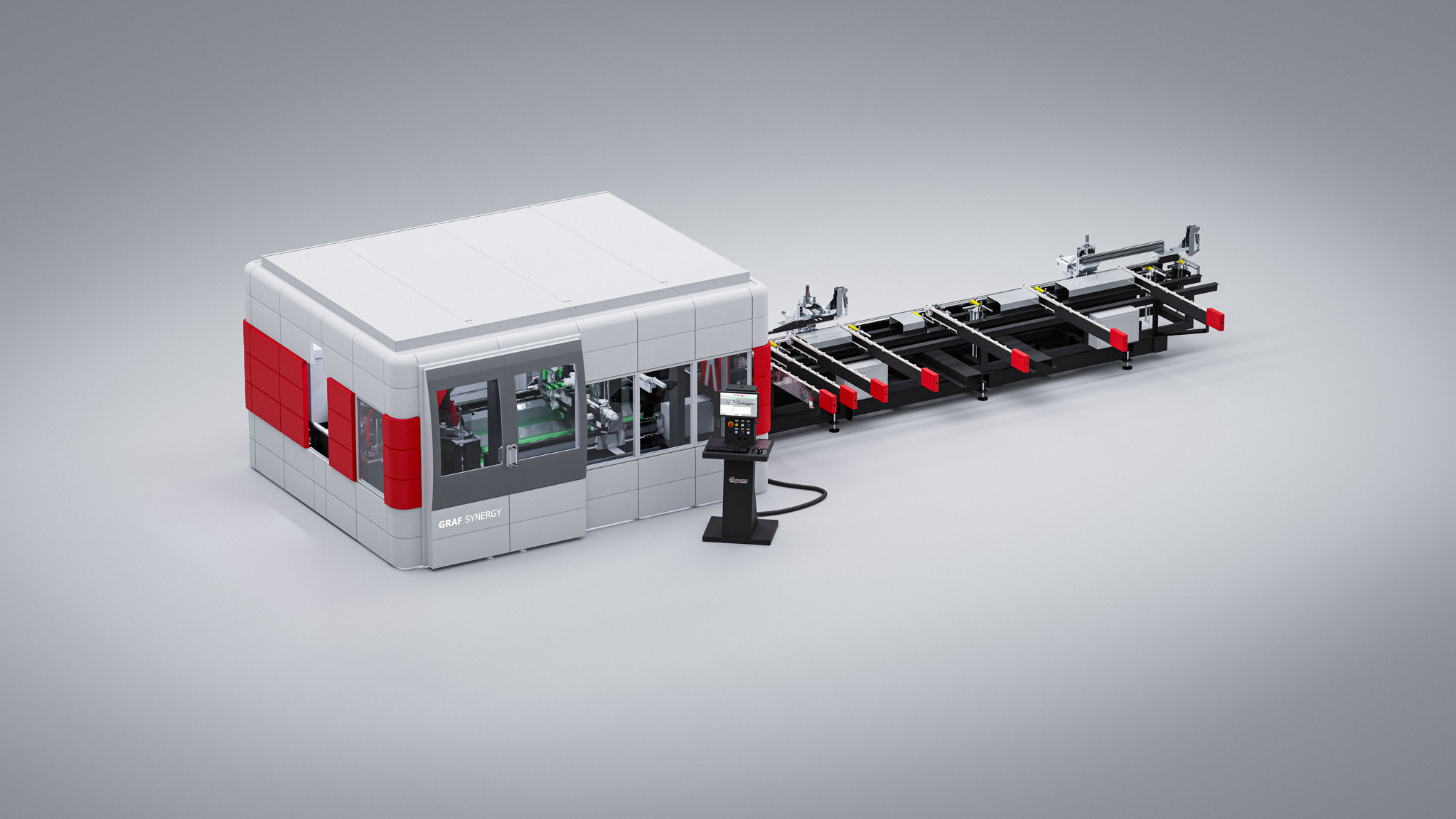

Cutting and processing, all in one facility

FAB CUT PLASMA is a CNC cutting centre that combines descending blade cutting with plasma technology, integrating all the necessary processes on metal reinforcements: slots, holes, notches, and cutting.

Managed by a 4-axis CNC system, it allows for high precision and automation.

The system can be configured to perfectly synchronise with the GRAF Synergy PVC centres, optimising the entire production flow.

The advanced software allows for the automatic import of production lists and includes intelligent systems for managing cutting and leftovers.

Why choose the FAB CUT PLASMA?

- A unique combined system. Processing and cutting integrated into a single automated solution.

- Reduced execution times. Simplifies and speeds up operations on reinforcements.

- Synchronous PVC/metal production. Aligned with PVC cutting center workflows for more streamlined cycles.

- Continuous optimization. Fly Optimizer for scrap reuse and waste minimization.

- Long-term reliability. Electronic blade wear monitoring and robust construction.

Product Details

FAB CUT PLASMA is a CNC cutting centre that combines descending blade cutting with plasma technology, integrating all necessary processes for metal reinforcements: slots, holes, notches, and cutting.

Managed by a 4-axis CNC system, it allows for high precision and automation.

Machine dimensions

Length: 14,525 mm

Width: 3,400 mm

Height: 2,800 mm

Weight: 2,850 kg

power supply and consumption

Installed power: 13 kW

Voltage: 400 V

Air consumption: 1,200 Nl/min

Minimum pressure: 7 bar

Performance and operators

- Up to 240 windows/8h (1 sash)*

- Operators required: 1

(*depending on metal type and section)

Workable profiles

Length: 700 – 6,500 mm

Width: 20 – 80 mm

Height: 20 – 60 mm

Operational modules

Work Form

- Structure: 4-axis CNC rotary plasma

- Operations: drilling, slots, and recesses on metal profiles

Modulo di Taglio

- Structure: 1 Ø 350 mm blade

- Movement: Downward

- Angle: Fixed 90° cut

Loading Form

- Magazzino max 9 barre

- Spintore con motore brushless e cremagliera

- Caricamento tramite cinghioli

Discharge Form

- Unloading with pneumatic extractor

- Table belt conveyor with safety photocells

- Maximum capacity 10 pieces

Optional available

- Optional plasma unit

- Clamping unit axis-controlled clamps

- Blade descent axis-controlled

- Blade rotation inverter for current control

- Second unloading clamp axis-controlled

- Automatic unloading table 5,000 mm

- Steel belt for collecting unloaded profiles

- Blade-only cutting setup (simplified version)

A single system for complete processing of metal reinforcements. Contact us for a technical demo of the FAB CUT PLASMA.