FAB CUT F1

CNC Cutting and Processing Centre for PVC Profiles

Automate the cutting and processing of profiles with maximum precision, saving both time and materials.

Perfect if you want:

- Drastically reduce bar waste thanks to software optimization

- Achieve perfect processing even on non-straight bars

- Increase productivity with a single operator

- Automate the complete cutting and drilling cycle in a compact space

- Integrate sensors, modules, and analysis software with an Industry 4.0 approach

Request the technical brochure now or speak with an expert.

Automate the cutting and processing of profiles with maximum precision, saving both time and materials.

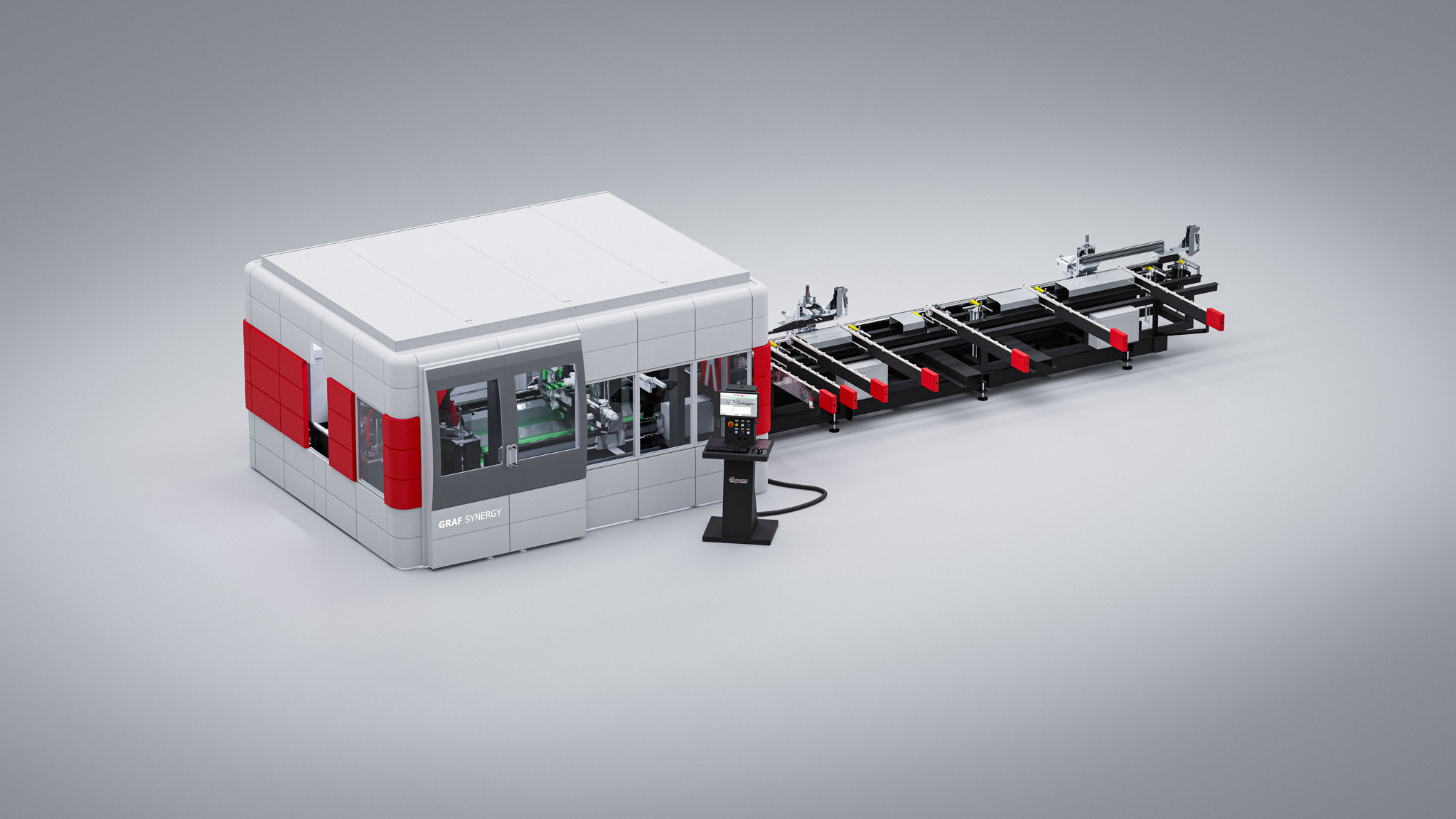

The FAB CUT F1 is a 5 or 6-axis CNC machining centre that represents the most advanced solution for cutting and processing PVC profiles. Equipped with the latest innovative technologies, it integrates cutting, drilling, milling, and marking functions into a single system, automatically managing the entire process with consistent precision over time.

Ideal for companies looking to automate and optimise production, it is compact, high-performing, and easily integrable into modern Industry 4.0 workflows. Intelligent management of cutting lists reduces material waste and machine downtime, ensuring a quick and measurable ROI.

5 reasons to choose the FAB CUT F1

- Total optimization of production lists. GRAF Synergy software enables the use of the fewest possible bars, reducing waste and maximizing efficiency.

- Ultra-precise cutting and drilling. The CNC clamp with hundredth-millimeter reading and automatic alignment system ensure consistent results even with deformed bars.

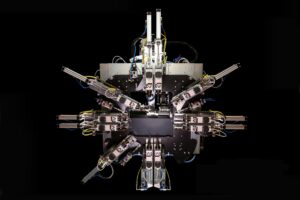

- High processing speed. Module with 6 (expandable to 12) High-Speed spindles and an ascending Ø500 mm blade for clean and fast cuts.

- Intuitive use, even for inexperienced operators. Simple interface and automated cycle management reduce training needs and speed up setup.

- Industry 4.0 integration. Compatible with management systems, data analysis, and remote control—ready for the future.

Product Details

FAB CUT F1 is designed to fully automate the main processes required in the production of PVC window frames.

Dimensions

Length: 14,900 mm

Width: 3,400 mm

Height: 2,500 mm

Weight: 3,000 kg

power supply and Consumption

Potenza installata: 14 kW

Tensione: 400 V

Consumo aria: 120 Nl/min

Pressione minima: 7 bar

Performance

Up to 180 single-pane windows in 8 hours*

*Depends on the type of profile and required processing

Operators required: 1

Workable profiles

Length: 700 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 130 mm

Supported features and processes

FAB CUT F1 is designed to fully automate the key processes required in the production of PVC windows. The high-speed working module supports:

- Handle, cylinder, and hinge holes

- Condensate drain slots

- Strike plate marking

- Ventilation holes

- Lock recesses

- All custom operations required on PVC profiles

The cutting module features an upward blade of Ø 500 mm (optional Ø 550 mm) for precise cuts at -45° / 90° / +45°, even on profiles with seals.

Options and configurations

FAB CUT F1 adapts perfectly to different production needs thanks to a complete range of options:

- 12-spindle configuration

- Blade rotation with brushless motor for intermediate angle cuts

- Bar gripping system with CNC clamp on prismatic guides

- Short bar loading from 400 mm

- Unloading module with output on the opposite side of loading

- Chip conveyor, dust extractor, soundproof cabin

- Connection to 1 or 2 ASG-E screwdriving centers

- Manual or automatic labeling machine

- Profile height/width sensors for error control

- Version for aluminum processing, transom end-milling, V-Notch

Technology and automation

The entire architecture of the FAB CUT F1 is designed to ensure efficiency, precision, and control. The management software allows you to:

- Automatically import and optimize cutting lists

- Analyze production data with the STATS module

- Recover pieces with the Recover option

- Measure and reuse scraps thanks to Fly Optimizer

The smart sensors and CNC architecture make it fully integrable into Industry 4.0 processes, featuring remote control, performance analysis, and predictive maintenance.

Contact us now to receive the complete brochure or to request a personalised demo.