FAB CUT 3BS

High productivity CNC cutting and working centre for PVC windows

The integrated solution for the cutting and automatic processing of PVC profiles: maximum speed, hundredth precision, and resource optimisation

Perfect if you want:

- Dramatically increase production while reducing downtime and waste

- Work with complex profiles or non-standard sections

- Optimize raw material usage with intelligent software

- Automate the production flow with Industry 4.0 in mind

- Rely on an intuitive interface, suitable even for inexperienced operators

Request the technical brochure now or speak with an expert.

The integrated solution for the automatic cutting and processing of PVC profiles: maximum speed, hundredth of a millimetre precision, and resource optimisation.

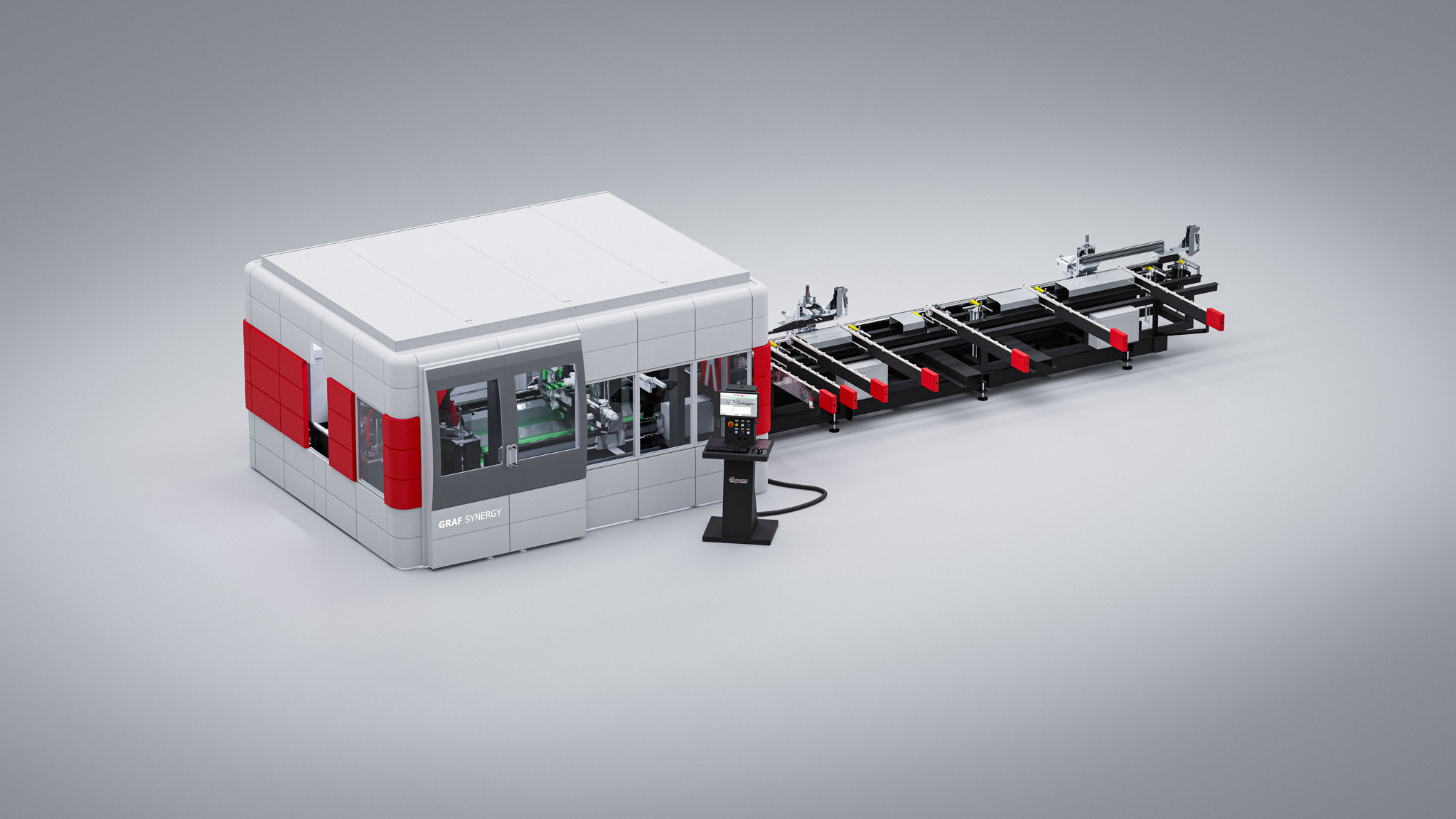

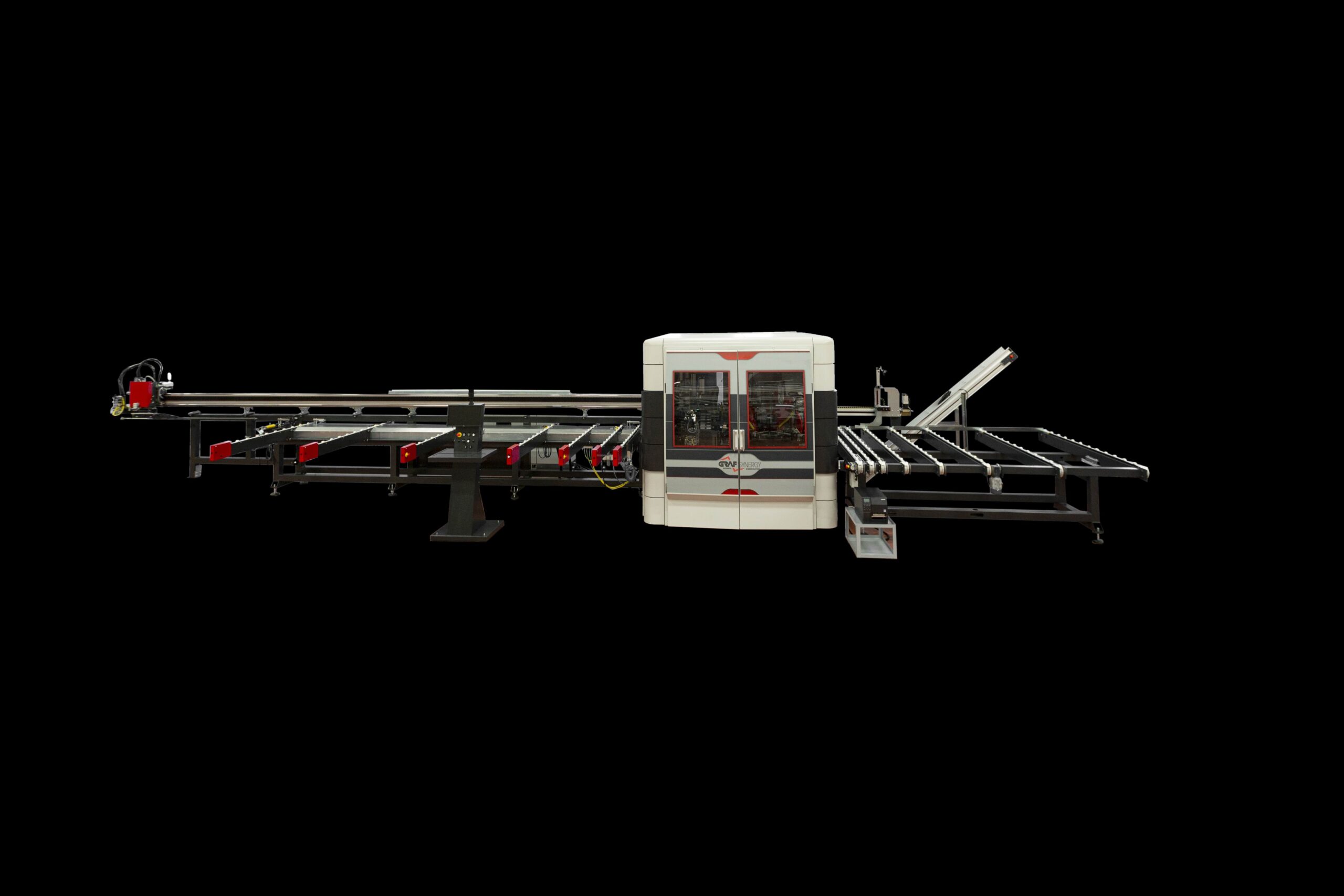

The FAB CUT 3BS is a CNC cutting and working centre with 12 controlled axes, designed for window manufacturers aiming for the highest levels of productivity, up to 250 single-leaf windows in 8 hours, without compromising on precision, reliability, and operational continuity.

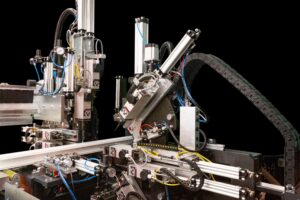

The configuration consists of an automatic loading warehouse (8 bars), a CNC gripper with 2 axes controlled by linear motors and hundredth reading, two independent working modules with 11 High Speed spindles on a split centre, and a horizontal cutting module with 3 synchronized blades Ø550 mm.

Thanks to the integrated management software, the system optimises the use of bars and records every machine activity. The plant is equipped for Industry 4.0, featuring remote monitoring and complete management integration.

5 Reasons to Choose FAB CUT 3BS

- Maximum speed and continuous operation. Two independent work modules with 11 High-Speed spindles, plus a cutting module with 3 synchronized blades, ensure consistent performance even on complex cycles.

- Guaranteed hundredth-millimeter precision. Automatic alignment system and CNC clamp with position reading via magnetic band: perfect operations even on non-straight bars.

- Reduced waste and costs. GRAF Synergy software optimizes production lists, reducing the number of bars required.

- Wide versatility and profile compatibility. Automatically processes profiles from 500 to 6,500 mm, with sections up to 130×180 mm. All required PVC operations are supported.

- Simplified and connected management. Intuitive software, complete operational monitoring, and Industry 4.0 readiness connected to management systems.

Product Details

The FAB CUT 3BS performs all standard and special operations in the PVC window frame sector, featuring two independent working modules, equipped with a total of 11 High Speed spindles. The horizontal cutting module with 3 blades Ø550 mm allows for cuts at -45° / 90° / +45°, even on profiles with seals.

Dimensions

Length: 15,250 mm

Width: 3,400 mm

Height: 2,800 mm

Weight: 4,500 kg

Performance

Cycle time: Up to 250 frames/8h* (depending on profiles and processing)

Strongly required operators: 1

power supply and Consumption

Installed power: 22 kW

Power Supply: 400 V

Air consumption: 180 Nl/min

Minimum pressure: 7 bar

Workable profiles

Profile length: 500 – 6,500 mm

Profile width: 40 – 130 mm

Height: 40 – 180 mm

Supported features and processes

Main processes:

- Handle, cylinder, hinge, and ventilation holes

- Condensate drain slots

- Lock recesses

- Strike plate marking

- Angle cuts on PVC profiles

Optional features and custom configurations

The FAB CUT 3BS is customizable with a wide range of options to suit any production requirement:

- Additional spindle (12°)

- Laser for tool breakage detection

- STATS: software for production data analysis (daily, weekly, monthly, yearly)

- Fly Optimizer: automatic detection of bar remnants and list optimization

- Recover Option: reinsertion of defective pieces into a new list

- Custom solutions for special profiles (based on technical analysis)

- Motorized unloading table on the opposite side

- Chip conveyor 1,000 or 2,000 mm

- Two-bag dust extractor

- Labeling machine manual or automatic with applicator

- Single or dual laser for profile marking

- Custom soundproof cabin

- Preparation for connection to 1 or 2 ASG-E centers

Integrated technology and automation

The FAB CUT 3BS combines 12-axis CNC management, intuitive proprietary software, and an automatic alignment system to deliver the highest levels of precision,

efficiency, and control.

- Automatic import of cutting lists

- Real-time bar optimization

- Complete machine cycle monitoring

- Connection to management systems

- Industry 4.0 compatibility

Do you want to discover how FAB CUT 3BS can enhance your production?

Request the complete brochure or a personalised consultation with our experts.