F 164 ALU

Automatic milling machine for condensate discharge on aluminium profiles

Maximum precision in condensate discharge processing

Perfect if:

- Minimise cycle times in milling operations

- Milling condensation drains on doors and frames with a single machine.

- Prevent rework by using accurate reference points.

- Using an intuitive machine, even with untrained operators.

- Quickly switch between working on different profiles.

- Maintain order and safety thanks to the compact and rational structure.

Request the technical brochure now or speak with an expert.

Maximum precision in condensate discharge operations

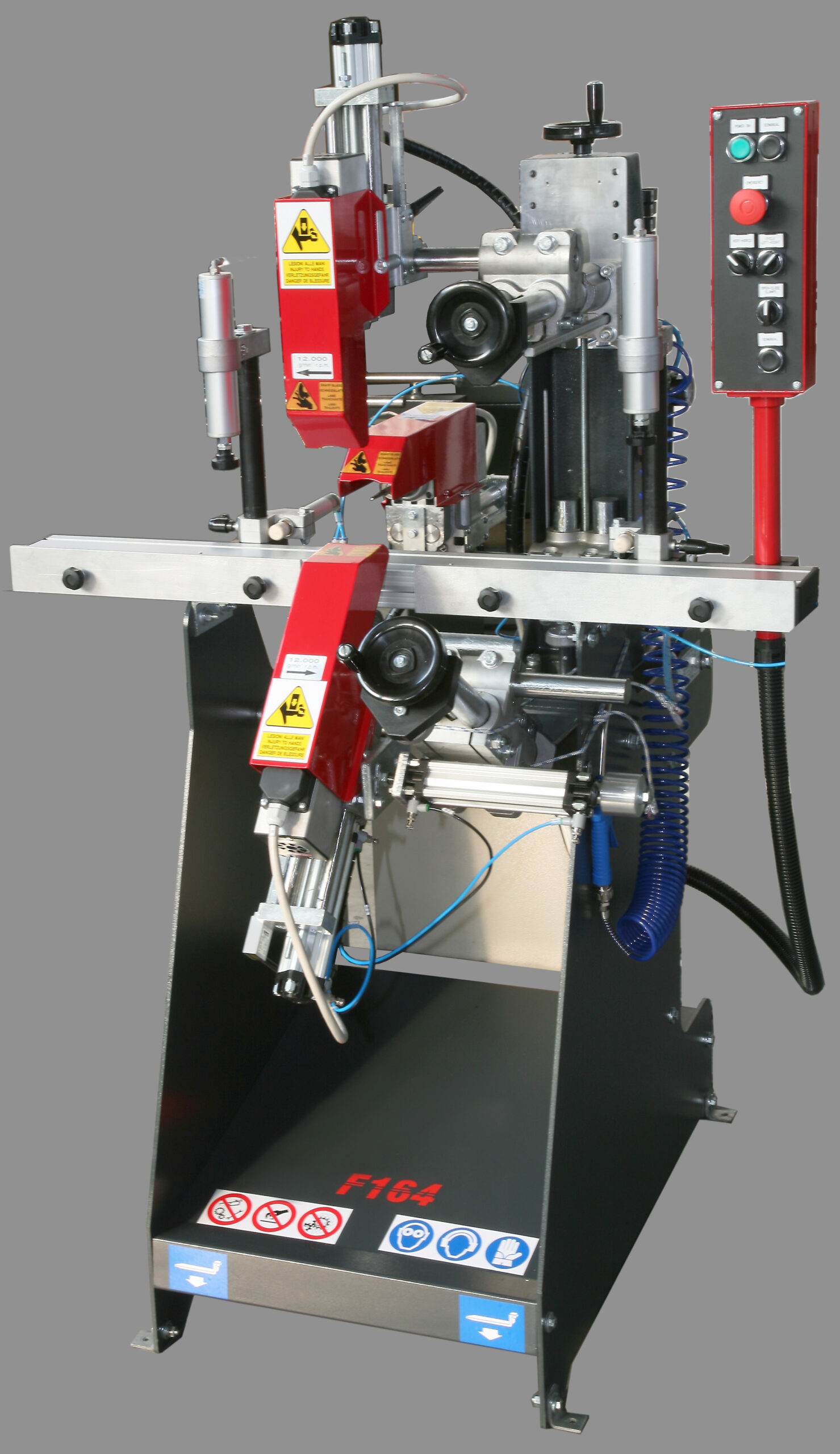

Designed to ensure speed, ease of use, and zero rework, F 164 ALU is the automatic milling machine dedicated to creating drain slots on aluminium profiles. With its compact structure and three oil-pneumatic spindles, it is ideal for those seeking an efficient machine that is easy to adjust and suitable for flexible production.

Perfect for companies working with both frames and panels, the F 164 allows for combined processing in three directions, which can be selected directly from the panel. The cycle is fully automatic, activated safely via a two-hand control, while the retractable stop references ensure speed and repeatability of operations.

5 reasons to choose the F 164 ALU

- Lightning-fast cycles. Milling takes place in extremely short times thanks to the three high-frequency electrospindles.

- No maintenance on spindles. HF motors do not require regular servicing, reducing downtime and management costs.

- Maximum operational flexibility. Automatic management of the exchange between internal and external discharges, with quick selection from the panel.

- Quick and intuitive adjustments. Knobs and mechanical stops allow the operator to set cycles in just a few seconds.

- Secure and precise workpiece clamping. The horizontal and vertical pneumatic vices ensure stability during every machining operation.

Product Details

The F 164 is specifically designed for the milling of drainage slots, featuring automatic positioning and selection of the processing type (door or frame) directly from the panel. The system allows operation in three different directions, combined in pairs, ensuring maximum versatility in managing drainage geometries. Thanks to the pneumatic movement of the electro-spindles and its compact configuration, the cycle remains stable, precise, and repeatable, even for medium-small batches.

Dimensions

Length: 1,300 mm

Width: 1,200 mm

Height: 1,900 mm

Weight: 235 Kg

Performance

Operator required: 1

Mode: automatic cycle with dual activation

Productivity: varies depending on manual organisation

power supply and Consumption

Installed power: 1.5 kW

Voltage: 230 V single-phase

Air consumption per cycle: 15 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Width: from 40 to 120 mm

Height: from 40 to 180 mm

Length: depends on the bar used

Supported features and processes

The F 164 is specifically designed for the milling of condensation drain grooves, featuring automatic positioning and selection of the processing type (door or frame) directly from the panel. The system allows operation in three different directions, combined in pairs, ensuring maximum versatility in managing drain geometries.

Thanks to the pneumatic handling of the electrospindles and the compact configuration, the cycle is stable, precise, and repeatable, even for medium-small batches.

Optional and configurations

To accommodate various layout requirements, the F 164 ALU can be equipped, upon request, with:

- SX+DX side supports 1,500 mm, useful for supporting long profiles and improving load ergonomics.

This optional configuration allows for better management of production flows even in limited spaces, optimising setup times.

Technology and Automation

The control panel allows for simplified management of cycles, with quick selection between door and frame modes. The concealed stop references and mechanical controls (knobs and stops) enable precise and fast settings.

The machine is compatible with flexible production processes and can be easily integrated into semi-automatic environments or incorporated into larger production lines.

Contact us to find out if F 164 ALU is the right solution for your production.