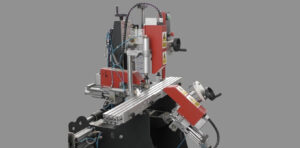

F 164

Automatic milling machine for condensate drainage on PVC and aluminium profiles

Fast and precise milling in three directions for door and frame profiles

Perfect if:

- You need to create condensate drain holes quickly and in a standardised manner.

- You work with both door profiles and frames and want a single machine for both.

- Are you looking for a compact solution that is easy to integrate even in small spaces?

- Do you want to enhance operator safety with a two-handed control?

- You need quick changes between internal and external cycles.

- Do you prefer equipment that is reliable and requires no regular maintenance on engines?

Request the technical brochure now or speak with an expert.

The F 164 milling machine is the compact and automatic solution for creating condensate drain slots with precision and without interruptions.

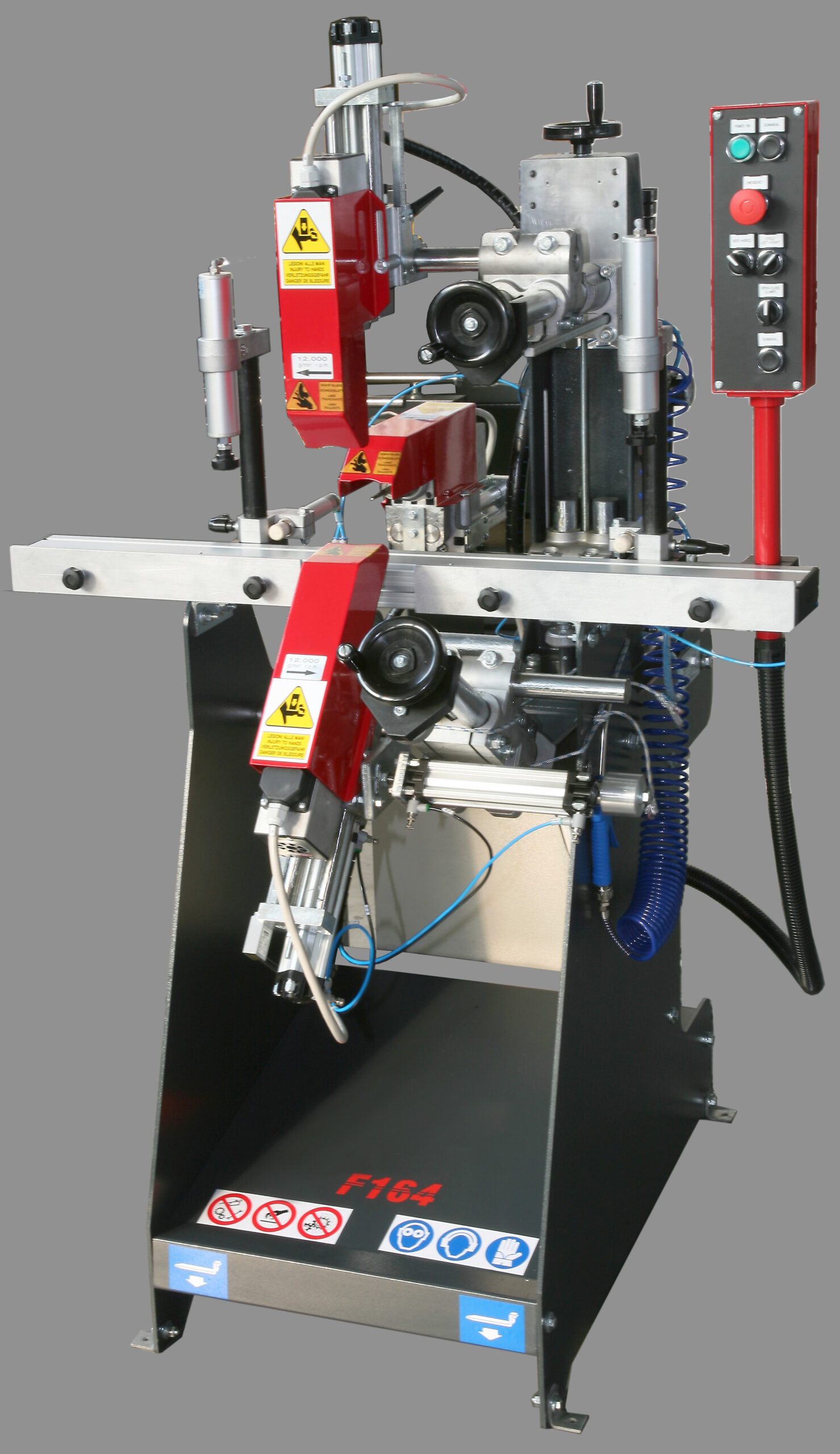

Designed to meet the needs of those working with PVC and aluminium profiles, this automatic machine ensures maximum efficiency thanks to its 3 high-frequency electro-spindles with pneumatic movement.

Ideal for both repetitive cycles and small batches, it features a two-hand safety control, integrated pneumatic clamps, and simple, reliable mechanical adjustment systems.

With the ability to select various processing cycles directly from the panel, the F 164 can adapt to the specific processing needs for doors or frames, ensuring speed, precision, and a reduction in operator errors.

5 reasons to choose F 164

- Zero maintenance motors. Equipped with high-frequency electrospindles, it ensures long-lasting performance without the need for regular maintenance.

- Maximum cycle speed. The automatic cycle completes each operation in extremely short times, boosting daily productivity.

- Simplified internal/external passage. Automatic condensate drain switching, with panel selection for leaf/frame cycles or left/right.

- Intuitive adjustments. Dials and mechanical stops allow for quick parameter settings, even by inexperienced operators.

- Precise and secure profile clamping. Two pairs of pneumatic clamps and retractable references ensure stability and repeatability in the machining process.

Product Details

The F 164 is designed to perform condensate drainage slots on PVC and aluminium profiles, with automatic configurations for different types of processing.

Dimensions

Length: 1,300 mm

Width: 1,200 mm

Height: 1,900 mm

Weight: 235 kg

Performance

Operation: manual with automatic cycle

Operators required: 1

power supply and consumption

Installed power: 1.5 kW

Power Supply: 230 V – Single Phase

Minimum operating pressure: 7 bar

Air consumption: 15 Nl/min per cycle

Workable profiles

Profile Width: 40 ÷ 120 mm

Profile height: 40 to 180 mm

Length: dependent on the bar used

Supported features and processes

Thanks to the pneumatic movement of the three electro-spindles, the machine can mill in three combined directions – selectable based on whether working on a door leaf or frame – providing high versatility and adaptability in the production line.

Available services:

- Condensate drain holes

- Different modes for door/frame

- Selectable SX/DX cycles from the panel

Optional and configurations

To further enhance practicality and flexibility in the workshop, the F 164 can be customised with:

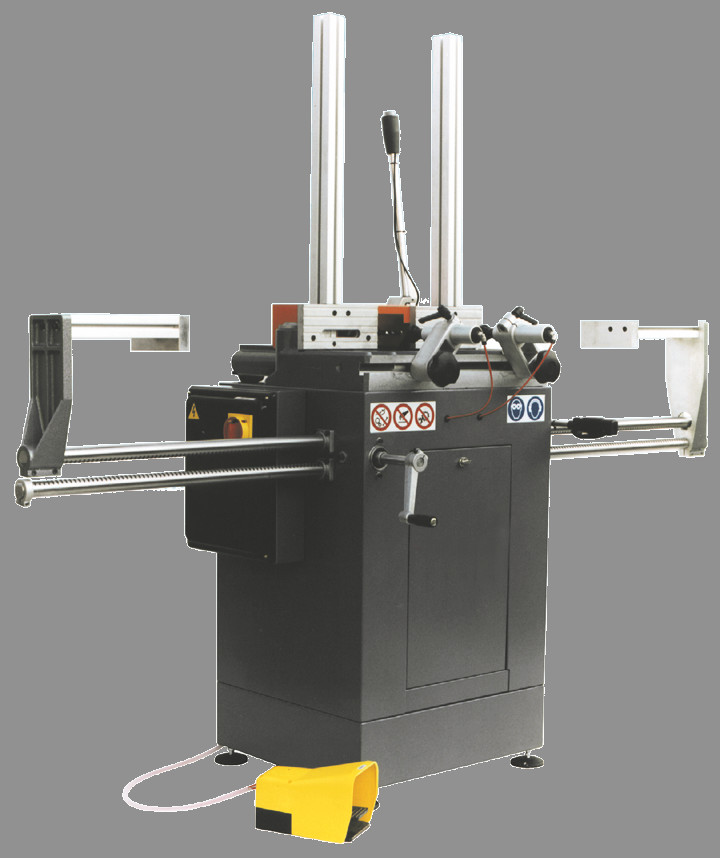

- SX+DX Side Supports measuring 1,500 mm to facilitate the loading and unloading of longer profiles.

- Adaptable configurations for the production layout

Each configuration is designed to seamlessly integrate into the client’s operational workflow.

Technology and automation

Although compact, the F 164 incorporates advanced technical solutions:

- Cycle control via integrated panel

- Quick selection of predefined programs for door/frame

Fast and Synchronized Pneumatic Movements

The machine is designed for efficient operation, even in contexts where speed of execution and ease of use are essential.

Want to know more?

Request the full brochure or a custom quote now to discover how the F 164 can enhance the productivity and quality of your milling department.