F 16

Automatic drilling machine for hinges on PVC frames

Precise post-welding drilling with automatic internal reference

Perfect if…

- You need to punch frames of various sizes quickly and accurately.

- Do you want to automate the hinge assembly phase?

- You have limited space available in the workshop.

- Are you looking for a counter that requires only one operator?

- Do you want to reduce errors and rework after welding?

Request the technical brochure now or speak with an expert.

Precise post-welding drilling with automatic internal reference

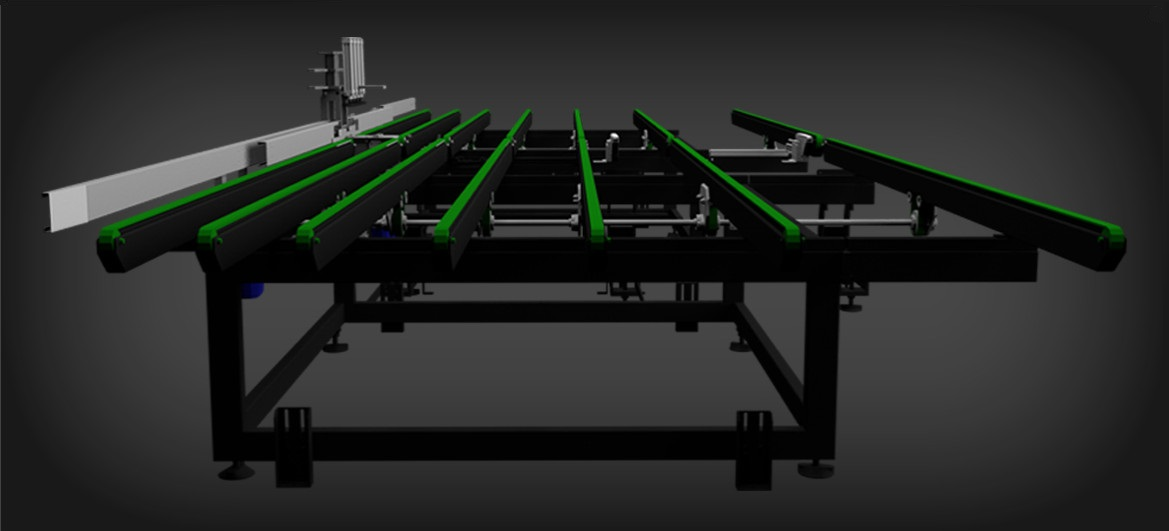

The F 16 from GRAF Synergy is an automatic machine designed to optimise the drilling phase of PVC frames, making it the ideal solution for companies seeking consistent precision, automatic cycles, and ease of operation.

Designed for processing frames of any size, it automatically drills hinge holes after welding, utilising an innovative measuring system for the glass stop groove to ensure perfect alignments.

Equipped with automatic depth adjustment and end-of-cycle reset, the bench ensures consistent results on PVC+Steel profiles.

The compact design, combined with a user-friendly interface and pneumatic clamp, makes it a reliable tool even in tight spaces.

5 reasons to choose the F-16

- Robust and compact structure. The workbench is made of electro-welded steel, designed to withstand the test of time and to fit into production environments with limited space.

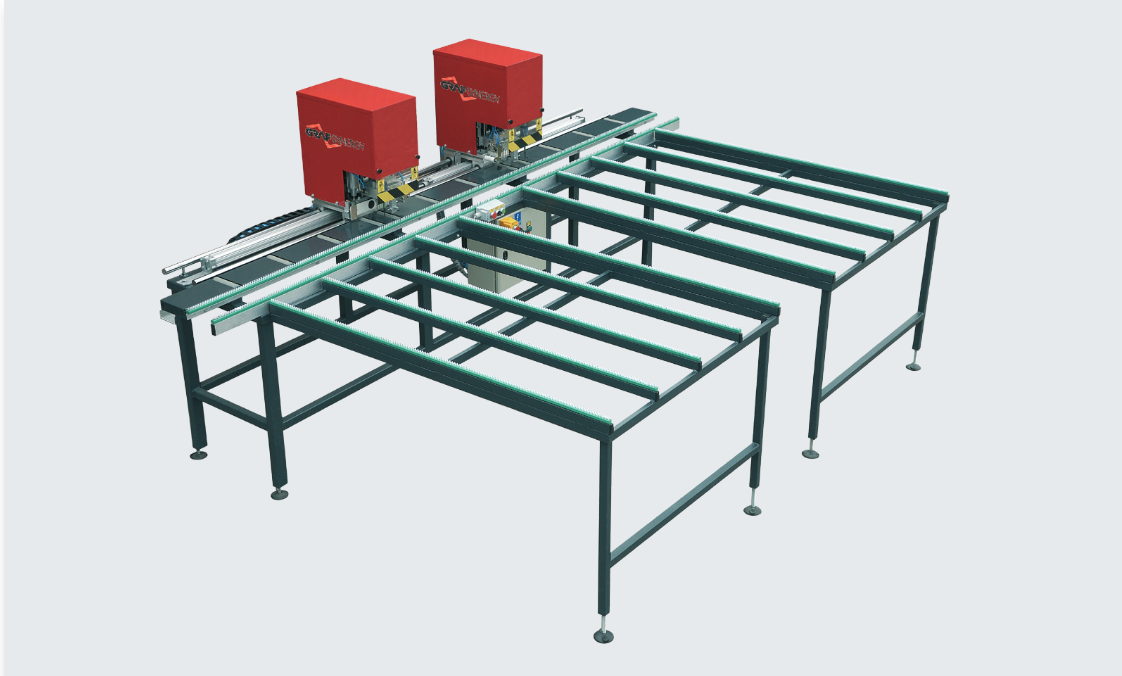

- Fully Automatic Drilling Cycle. The entire process is automated: from the positioning of the drilling heads to depth management, right through to zeroing at the end of the operation.

- Precision on every frame thanks to the internal reference. Intelligent automatic measurement system for the glazing bead groove, ensuring precise drilling for any profile size.

- Fast and Intuitive Programme Change. User-friendly digital management for quickly adjusting drilling settings, reducing setup times.

- Spacious work surface and simplified maintenance. A large workbench ideal for hinge assembly and a structure that requires minimal maintenance.

Product Details

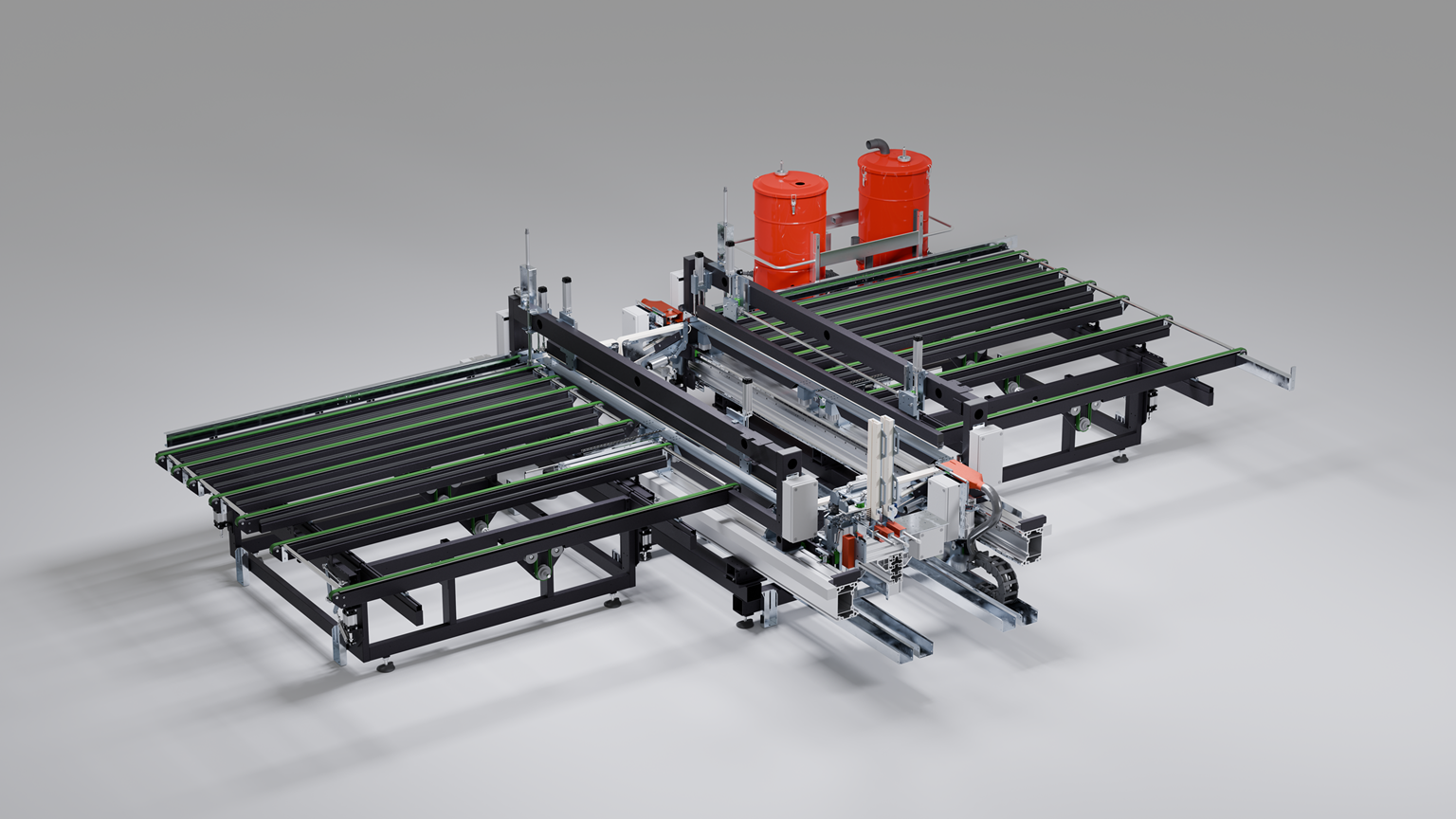

The F 16 bench is designed exclusively for drilling PVC frames, creating holes for hinges after welding, fully compatible with steel reinforced profiles.

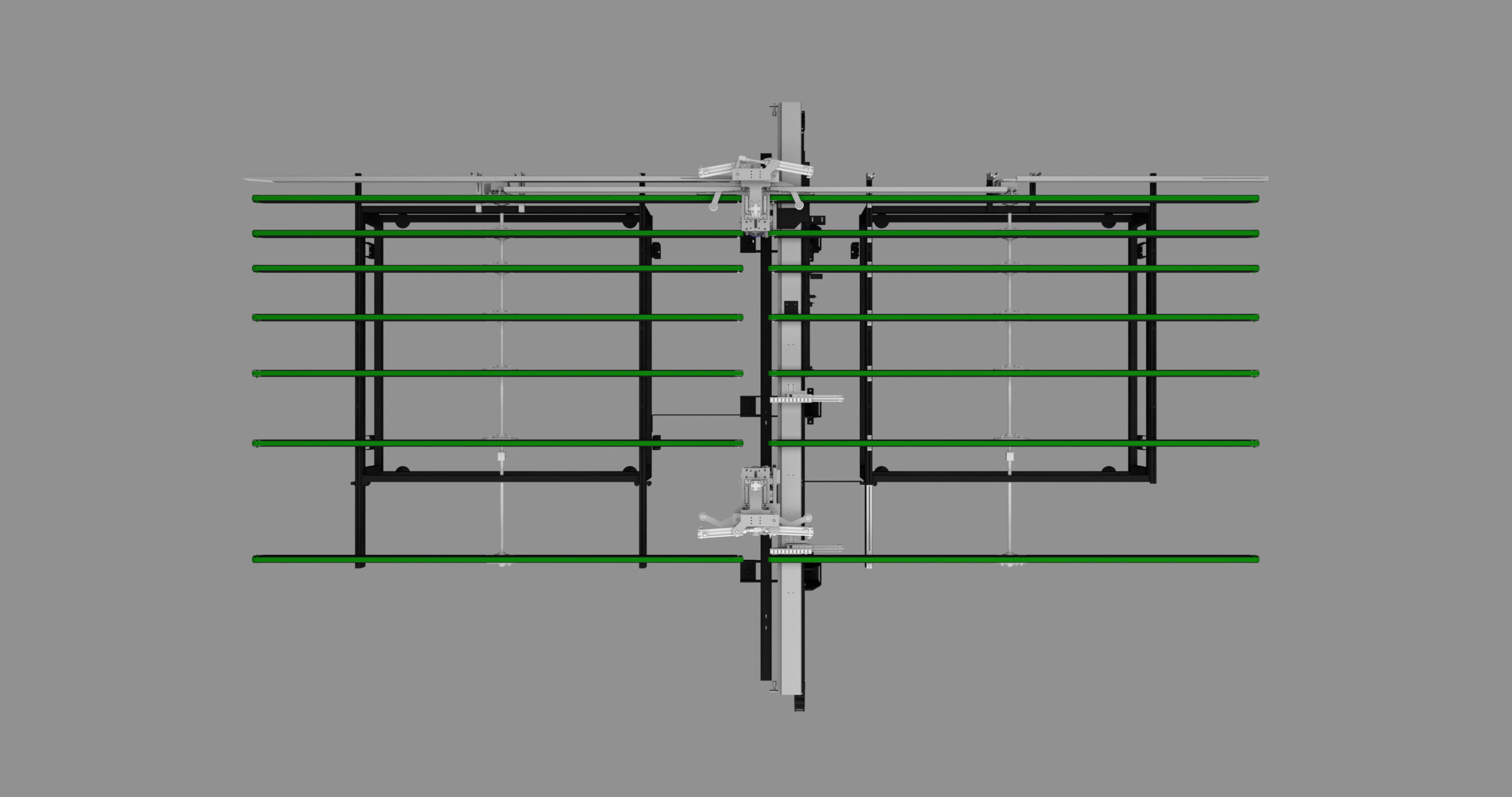

The two oleopneumatic descent drilling heads, mounted on double ground bars, ensure maximum precision. The frame is secured using high-clamping pneumatic vices, providing stability during operation.

Dimensions

Length: 3,150 mm

Width: 1,700 mm

Height: 1,200 mm

Weight: 400 kg

Performance

Operation: Manual

Strongly required operators: 1

Workable frames per day: based on manual productivity

power supply and Consumption

Installed power: 1.2 kW

Voltage: 400 V

Air consumption: 15 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Minimum frame size: 450 mm

Maximum frame size: 2,740 mm

Supported features and processes

Supported processes:

- Automatic drilling on PVC+Steel profiles

- Corner positioning guided by internal reference

Optional features and available configurations

The car is supplied in full standard configuration, without any additional options. Every essential feature is already integrated to ensure maximum ease of use and reduced maintenance.

Technology and automation

Although it is a compact and straightforward machine, the F 16 incorporates advanced automation:

- Automatic drilling depth regulator

- Automatic reset cycle

- Intuitive interface with a simplified control panel

Pneumatic tightening for safety and repeatability

Do you want to find out if the F 16 is suitable for your production?

Request the detailed brochure now or contact us for a personalised quote. Our team is available to discuss how to integrate the F 16 into your production line.