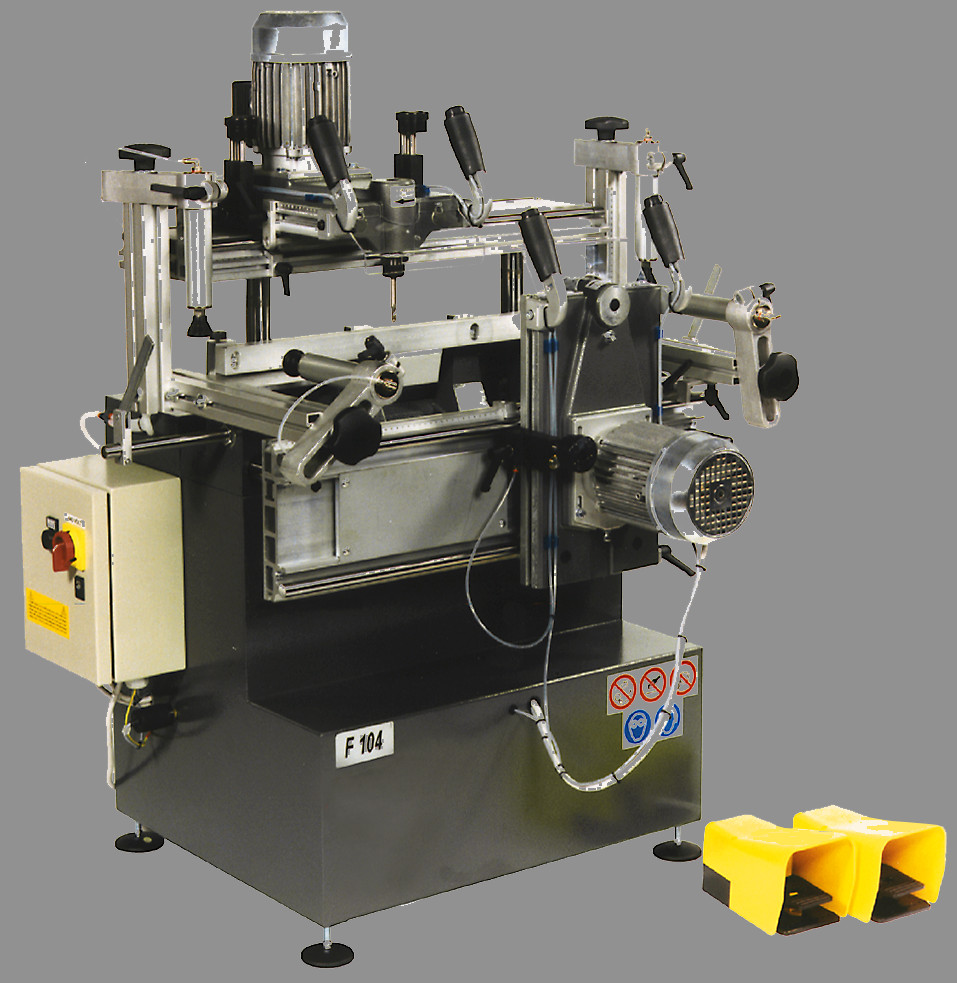

F 104

Double-head pantograph for vertical and horizontal machining

Maximum flexibility for precise milling on every side of the profile

Perfect if you want…

- Create notches and holes on all sides of the profile without any displacement.

- Work quickly even on small batches or custom productions.

- Achieve maximum visibility during milling with manual handling.

- Ensure compatibility with milling cutters of different diameters (10 and 12 mm).

- Adapt processes to different profiles using adjustable probes.

- Minimise clutter while maintaining efficiency and robustness.

Request the technical brochure now or speak with an expert.

Maximum flexibility for precise milling on every side of the profile

The F 104 pantograph from GRAF Synergy is the ideal solution for those seeking a compact, robust, and versatile tool for creating notches, holes, and slots in PVC and aluminium profiles.

Thanks to the dual copying head (one vertical and one horizontal), it allows processing on 4 sides without having to rotate or unlock the profile, ensuring speed, precision, and operational continuity.

Designed to provide maximum milling freedom both longitudinally and transversely, the F 104 stands out for its ease of use, the robustness of its steel structure, and the interchangeable templates with standard shapes, ensuring adaptability to various production needs.

5 reasons to choose F 104

- Four-Sided Machining Without Repositioning. With the double head (horizontal and vertical), you can mill each side of the profile in a single cycle, saving time and ensuring consistency.

- Maximum freedom and operational control. Manual handling allows for great precision in details and total visibility of the work area, making it ideal for special profiles or custom processing.

- Adjustable 3-Diameter Probes. Equipped with pneumatic probes compatible with 10 and 12 mm milling cutters, it adapts to various types of milling.

- Compact yet sturdy structure. With a footprint of just 1,200 x 1,000 mm, the machine offers robustness thanks to its steel base and leveling feet.

- Customisable upon request. A wide range of options available to optimise the production flow: roller conveyors, side supports, and stop blocks.

Product Details

The F 104 pantograph from GRAF Synergy is the ideal solution for those seeking a compact, robust, and versatile tool for creating notches, holes, and slots in PVC and aluminium profiles.

Dimensions

Length: 1,200 mm

Width: 1,000 mm

Height: 1,250 mm

Weight: 235 Kg

Performance

Operations: Manual

Operators required: 1

power supply and Consumption

Installed power: 2.2 kW

Voltage: 400 V

Minimum operating pressure: 7 bar

Air consumption: 15 Nl/min

Milling capacity

Vertical test (X-Y-Z): 490 x 140 x 140 mm

Horizontal test (X1-Y1-Z1): 315 x 120 x 130 mm

supported processes

The F 104 pantograph is designed to perform:

- Free milling on the longitudinal and transverse axes

- Fixed milling using copy templates

- High-precision cuts and holes on PVC and aluminium profiles

Each head is equipped with a standard jig and pneumatic probes for consistent repeatability.

Optional features and available configurations

To perfectly fit any production line, the F 104 can be equipped with:

- Stop block with plate 150 x 150 mm

- Left and right roller conveyor, 1,500 mm

- Support for left and right profile of 1,500 mm

These options make the machine ideal for those working with long profiles or requiring greater stability during milling.

Technology and automation

The F 104 model prioritises simplicity and direct control through manual operation. This choice is designed for those who seek:

- Total visibility of the processing

- Maximum flexibility in profile management

- A modest investment with a high operational return

Although not automated, the pantograph easily integrates into existing production lines and is compatible with just-in-time processing logic.

Do you want to find out if the F 104 is the right choice for your workshop?

Download the brochure or contact our experts for a tailored consultation. The GRAF Synergy team is here to help you configure the ideal machine for your production needs.