F 102 S

Single-head pantograph for drilling and milling on PVC and aluminium profiles

Maximum precision on all four sides, even in tight spaces: the essential pantograph for every workshop.

Perfect if…

- We work with PVC and/or aluminium profiles, frequently handling requests for custom drilling or slotting.

- Do you want to perform multi-sided milling without wasting time repositioning the profile?

- You have limited space in your workshop but don’t want to compromise on having a professional machine.

- Are you looking for a simple yet precise and flexible solution for all your needs?

- Do you want to maintain direct control over the processing, avoiding fully automated solutions?

Request the technical brochure now or speak with an expert.

The manual pantograph that combines flexibility, speed, and professional quality

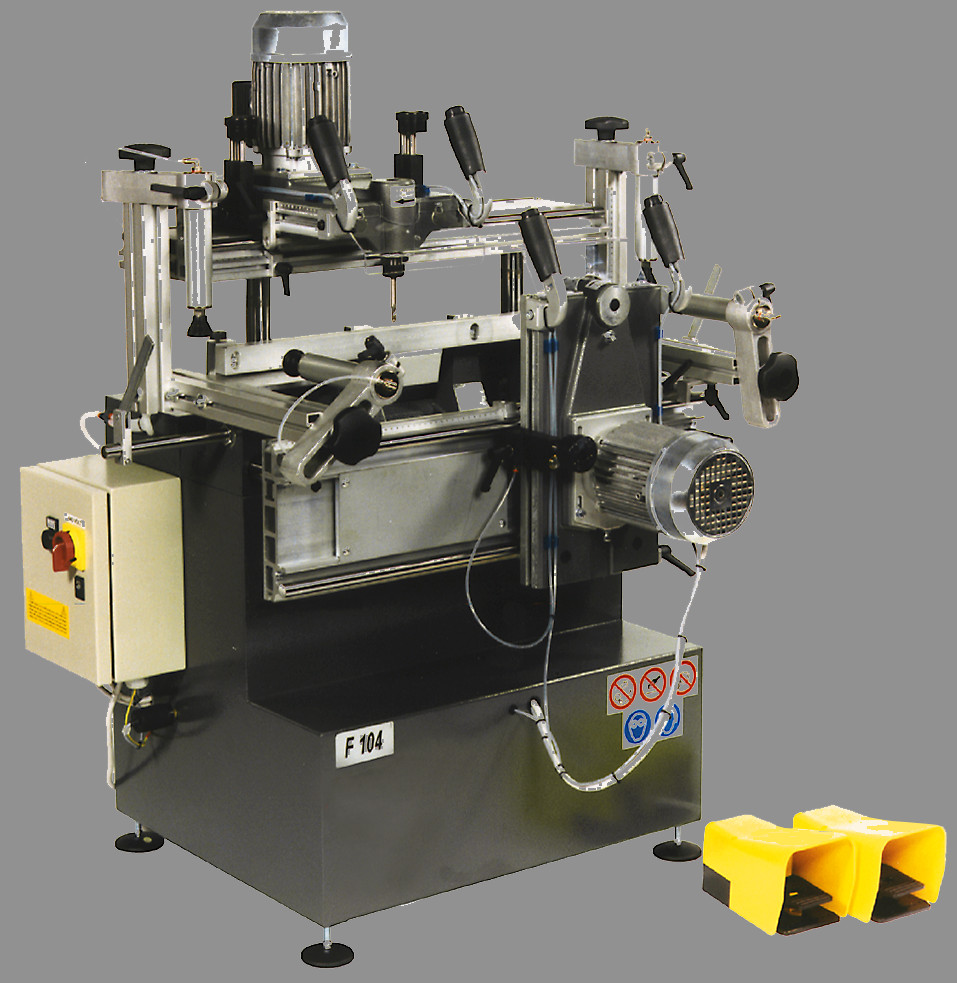

F 102 S is the single-head pantograph designed for precision through milling on PVC and Aluminium profiles.

Thanks to the copying system with templates and adjustable stops, it allows for the creation of slots, holes, and machining on four sides without having to unlock the piece: a compact yet highly functional solution for those seeking operational speed and maximum machining quality, even with minimal space requirements.

With a sturdy steel structure, manual handling, and a pair of pneumatic vices, the F 102 S is the perfect ally for artisan workshops and businesses seeking a reliable and precise machine, suitable for frequent and varied operations without compromise.

5 reasons to choose F 102 S

- Four-sided machining in a single setup. Thanks to the jig and adjustable stops, you can perform drilling, keyhole cutting, and milling without having to release the workpiece.

- Total operational flexibility. Manual handling, adjustable diameter touch probes in three sizes, and Ø10-12 mm milling cutters to meet every requirement.

- Uncompromising Compactness. With a length of just 1,050 mm and a width of 850 mm, it’s perfect for tight spaces.

- Maximum stability and precision. Steel structure with leveling feet and dual pneumatic clamps for secure locking.

- Ready for intensive use. Automatic utensil refrigeration, sturdy construction, and minimal maintenance: designed to last.

Product Details

The F 102 S allows for both simple and complex through processing on PVC and aluminium profiles, whether in a vertical or horizontal orientation. The machine is designed to ensure precision and repeatability in the most common milling operations within the window and door industry.

Dimensions

Length: 1,050 mm

Width: 850 mm

Height: 1,600 mm

Weight: 235 kg

Performance

Operations: Manual

Strongly required operators: 1

power supply and Consumption

Installed power: 1.1 kW

Power Supply Voltage: 400 V

Consumo aria: 10 Nl/min

Minimum operating pressure: 7 bar

Milling capabilities

X-axis travel: 490 mm

Y-axis travel: 140 mm

Axis Z Travel: 140 mm

supported processes

Main processes:

- Longitudinal and transverse milling (free)

- Fixed milling using a copying template

Drilling and slotting on 4 sides

Optional features and custom configurations

To enhance productivity and tailor the F 102 S to specific needs, optional accessories can be added to extend its functionality:

- Pneumatic control switches for quick change

- Stop plate with dimensions 150×150 mm

- Star stop with 4 positions

- Rollers and supports 1,500 mm left/right

- Profile centring stop with batten

Each accessory is designed to enhance ergonomics, reduce cycle times, and increase the precision of complex machining processes.

Technology and automation

Although it is a manually operated machine, the F 102 S incorporates highly reliable professional components.

The automatic mist cooling system ensures a long lifespan for tools and consistent performance even with repeated use. The mechanical interface is designed for simple and intuitive use, making it ideal for operators with minimal experience.

Contact us for a demo or a personalised quote.

Would you like to see the F 102 S in action or receive a personalised consultation?

Request the full technical brochure or Contact us now to discover how to integrate this solution into your workshop.