ESU

Efficient Screwdriving Unit: CNC Station for Screw Driving Reinforcements on PVC Profiles

Automatic screw driving, continuous productivity

Perfect if:

- Automate the process of screwing reinforcements onto PVC profiles.

- Minimise manual intervention online

- Ensure quick, precise, and repeatable fastenings.

- Work continuously with the dynamic table and the work centre.

- Optimising cycle times and productivity

- Integrate CNC parameters for position, depth, torque, and speed.

Request the technical brochure now or speak with an expert.

Automatic screwing, continuous productivity

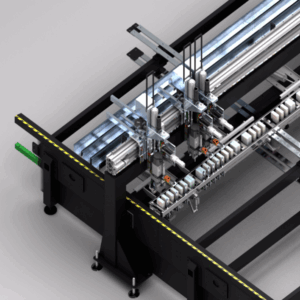

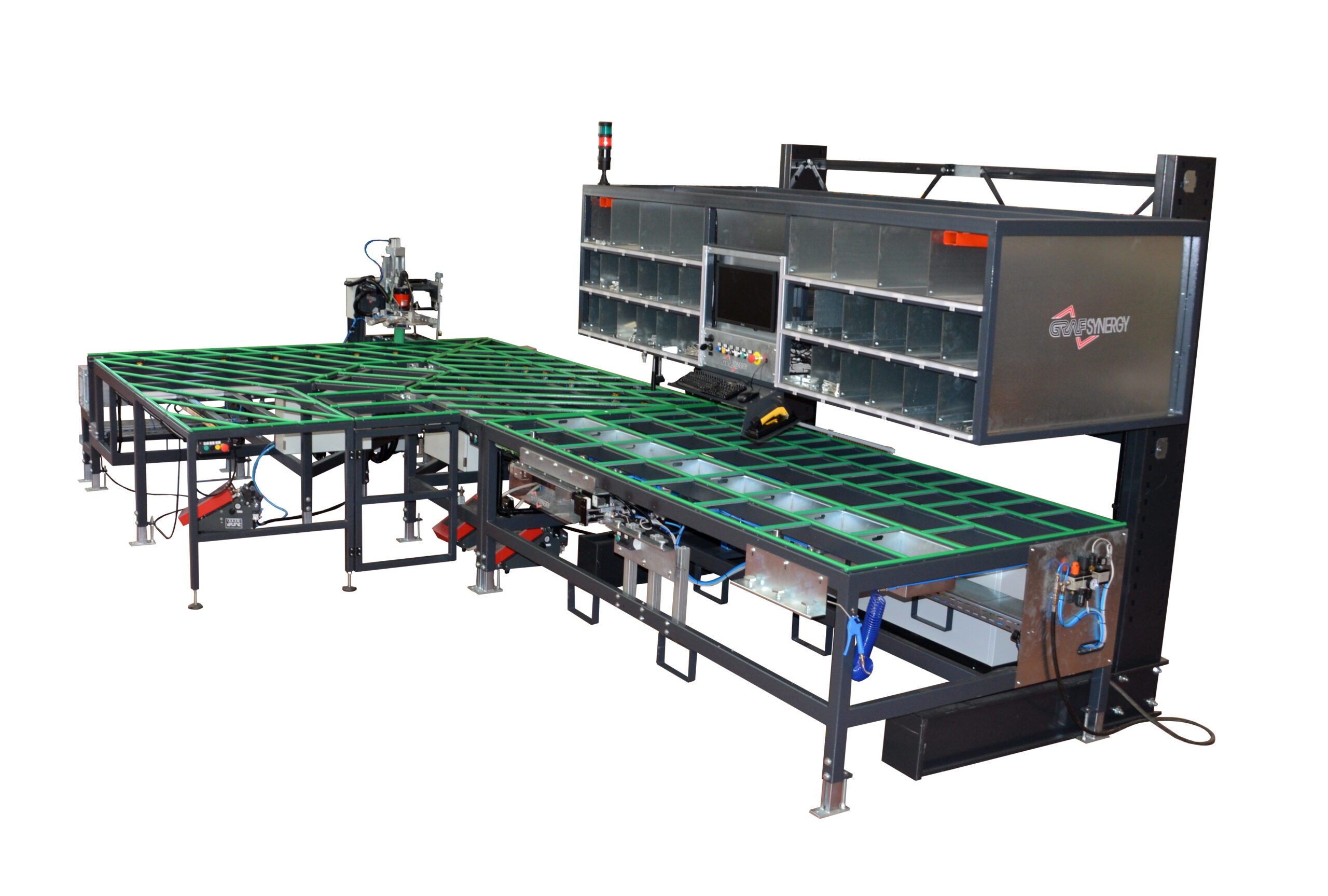

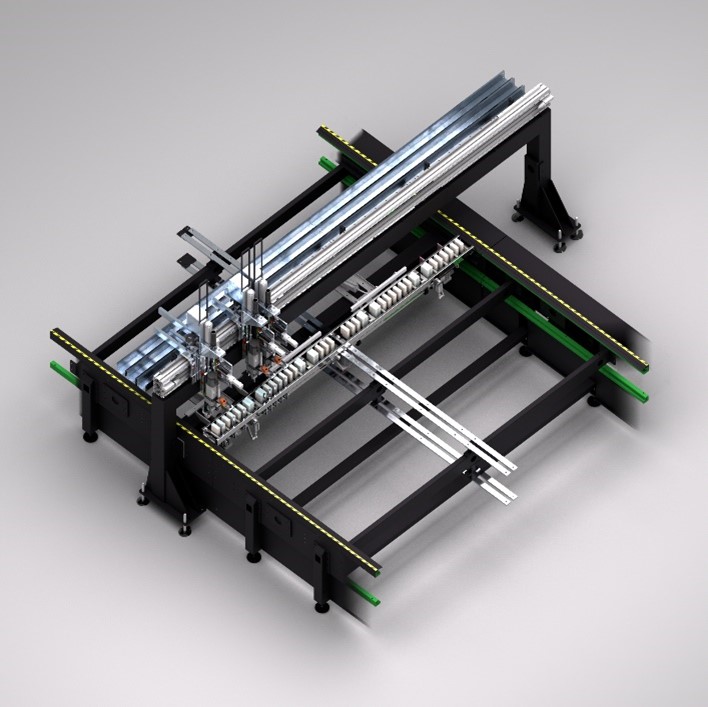

ESU is the CNC station from Graf Synergy dedicated to the automatic screwing of metal reinforcements within PVC profiles. It integrates directly into the production flow, working in line with the dynamic table and cutting and working centres, to achieve zero-time fastening of the reinforcements.

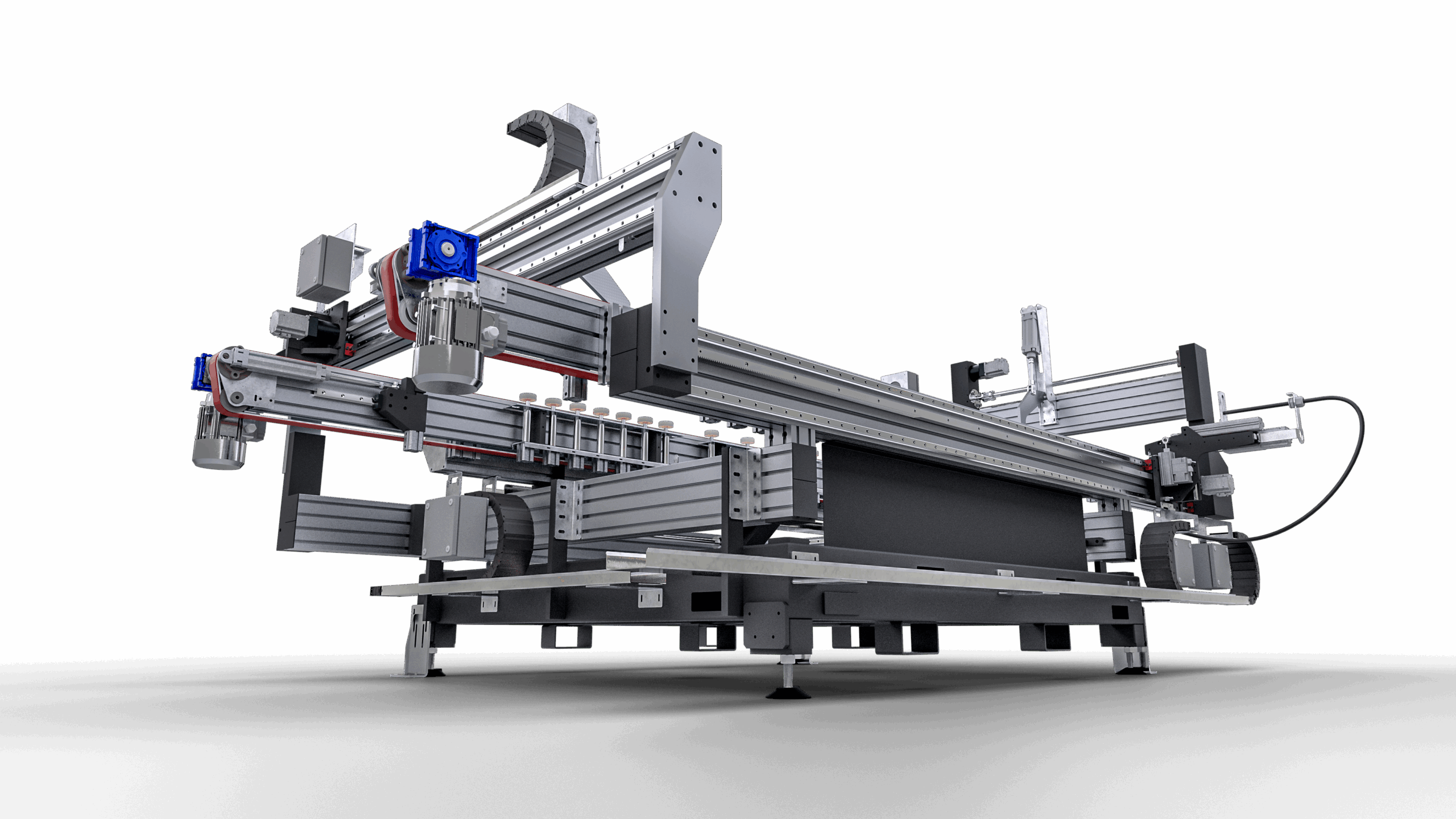

The machine is equipped with a mounting module that accommodates up to 4 brushless electric screwdrivers with automatic screw feeding. Each cycle is fully managed by CNC software to ensure speed, precision, and consistency with the processing parameters.

5 reasons to choose ESU

- Maximum speed at zero time. The processing takes place directly inline, during the production flow of the profile.

- Comprehensive Parameter Control. Dedicated CNC software for precise management of position, screw depth, torque, and speed.

- Brushless electric screwdrivers. Quiet, precise, and energy-efficient. They can work simultaneously or take turns.

- Total automation, reduced operator involvement. Just load the screws. Everything else is automated.

- Versatility with 4 screwdrivers and optional modules. The ability to mount up to 4 units, plus additional chargers for different screw sizes.

Product Details

ESU is the CNC station from Graf Synergy dedicated to the automatic screwing of metal reinforcements within PVC profiles. It integrates directly into the production flow, working in line with the dynamic table and cutting and working centres, to achieve zero-time fastening of the reinforcements.

Machine dimensions

Length: 4,500 mm

Width: 1,800 mm

Height: 2,700 mm

Weight: 2.500 kg

Power supply

Installed power: 6 kW

Power Supply: 400 V

Air consumption: 200 NI/min

Operating pressure: 7 bar

Operational features

- Number of screwdriving units: up to 4 (vertical)

- X-axis movement: automatic longitudinal

- Y-axis movement: automatic cross positioning

- Operating mode: CNC

- Operators required: for screw replenishment only

Usable profile dimensions

- Length: 350 – 4,000 mm

- Width: 40 – 130 mm

- Height: 40 – 120 mm

Types of work

- Automatic screwing of reinforcements onto PVC profiles

Integration

- Compatible with the Graf Synergy dynamic table.

- Compatible with CNC Cutting and Machining Centres

TECHNOLOGY AND AUTOMATION

ESU is designed to provide the highest level of automation in the reinforcement fastening phase. The brushless screwdrivers ensure high precision, low noise impact, and reduced energy consumption.

CNC control allows for the definition of every parameter in the screwing cycle, ensuring consistent quality across each piece. The software module coordinates the activity of the screwdrivers either alternately or simultaneously, depending on the number of screws to be inserted.

Perfectly integrable into Industry 4.0 systems, the ESU enables traceability of operations, interfacing with line management systems, and reducing operational workload.

Contact us to find out if the ESU is the right solution for your production.