CUT V

CNC Cutting Centre for Special Productions

The evolution of automated cutting tailored to meet the most complex needs.

Perfect for:

- Window manufacturers looking to automate the Special Productions department

- Workshops requiring cuts with extreme and intermediate angles

- Companies handling non-standard or not perfectly straight profiles

- Departments seeking precision, versatility, and advanced software

- Those aiming to reduce labor in the production cycle

Request the technical brochure now or speak with an expert

Innovation in Cutting for Custom Productions

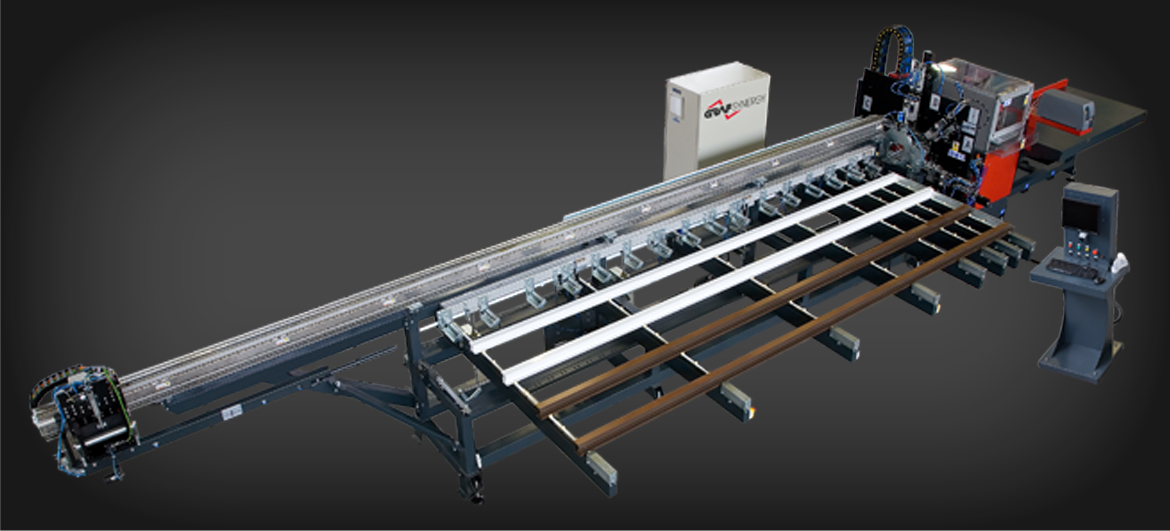

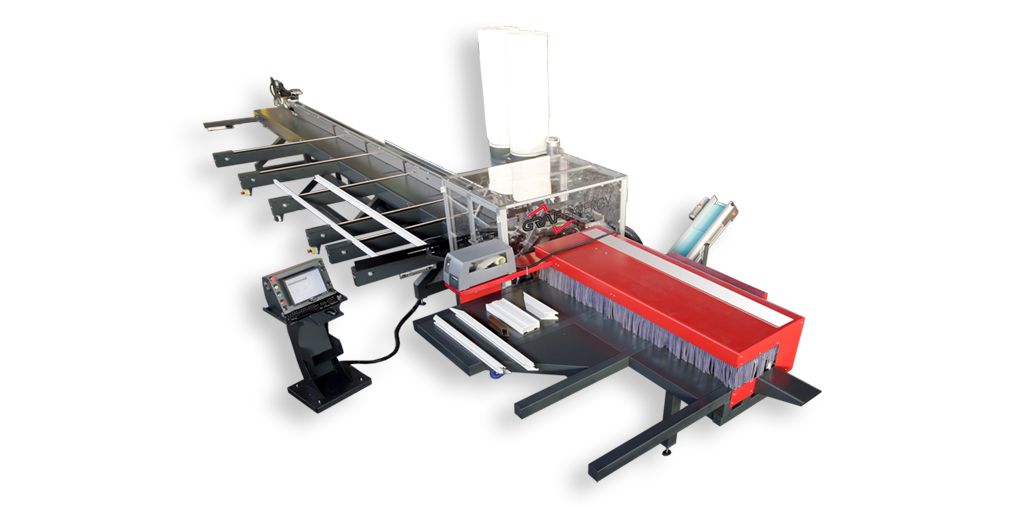

CUT V is a 4-axis CNC cutting centre designed to automate and simplify the machining of complex profiles.

Equipped with a 550 mm upward blade and a motorised angular cutting module, it allows for precise cuts even at intermediate angles (-22.5°/+22.5°), thanks to the brushless control and the centesimal reading on a magnetic band.

Equipped with a 10-bar loading magazine and a CNC gripper with a linear motor, it ensures maximum precision even with bars that are not perfectly straight, thanks to its automatic alignment system.

Why choose the CUT V?

- Designed for the Special Productions department. Automates the cutting of complex profiles with flexible and precise management.

- Advanced cuts on non-standard profiles. Allows cuts with extreme and intermediate angles thanks to angular rotation.

- Maximum precision on every bar. Automatic alignment and hundredth-millimeter reading to straighten each profile.

- Minimal labor, maximum output. Requires only one operator for loading and unloading.

- Advanced software for optimized production. Automatic list management and full traceability of the production cycle.

Product Details

The CUT V cutting module allows for angled cuts with an upward blade movement, and angles ranging from -22.5° to +22.5°, making it ideal for special profiles or complex sections.

The 4-axis system and profile alignment ensure maximum precision in any condition.

Dimensions

Length: 15,500 mm

Width: 2,800 mm

Height: 2,400 mm

Weight: 2.3 kg

Performance

Up to 240 square metres in 8 hours (1 panel)

Operators required: 1

power supply and Consumption

Installed power: 7 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption: 200 Nl/min

Workable profiles

Length: 700 to 6,500 mm

Width: 40 to 130 mm

Height: 40 to 180 mm

Optional features and available configurations

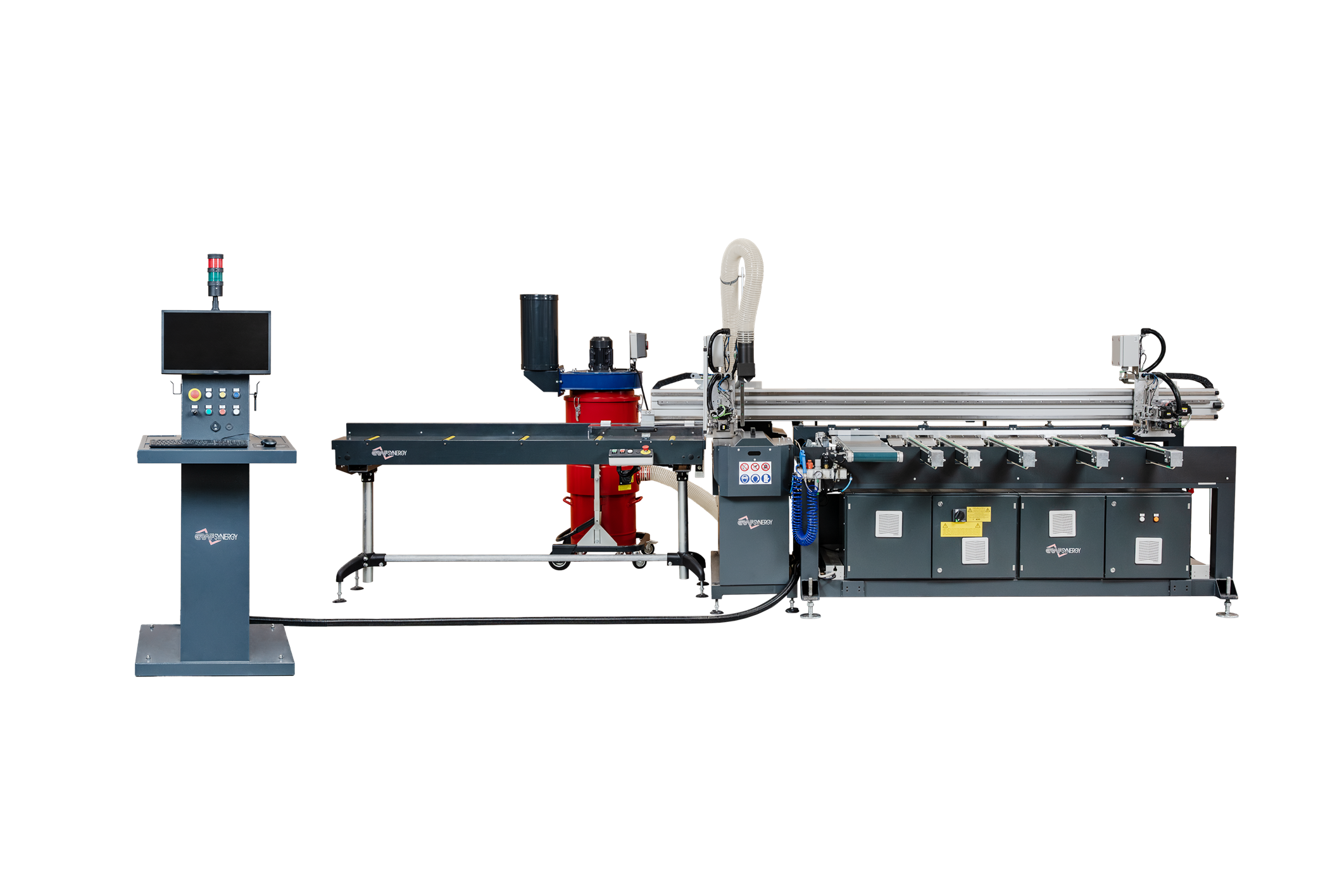

CUT V can be equipped with a wide range of options to enhance automation, flexibility, and control:

- Fly Optimizer: bar remnants optimization

- Recover Option: reinsertion of reusable pieces

- STATS: monitoring of operational data and KPIs

- Motorized unloading table on the opposite side

- Custom soundproof cabin

- Automatic or manual labeling machine

- Chip conveyor H 1,200 / 2,000 mm

- Two-bag dust extractor

- Motorized swivel for angles from -15° to +15°

- Automatic connection to ASG-E centers

- Custom solutions based on technical analysis for special profiles

Software integration and traceability

The CUT V management software allows for the import of lists, optimisation of bars, and complete traceability of operations. Fully integrable with ERP and MES systems, it is ideal for companies focused on the digitalisation of production.

Automate your special department and enhance every cut: contact us for a technical demo of the CUT V.