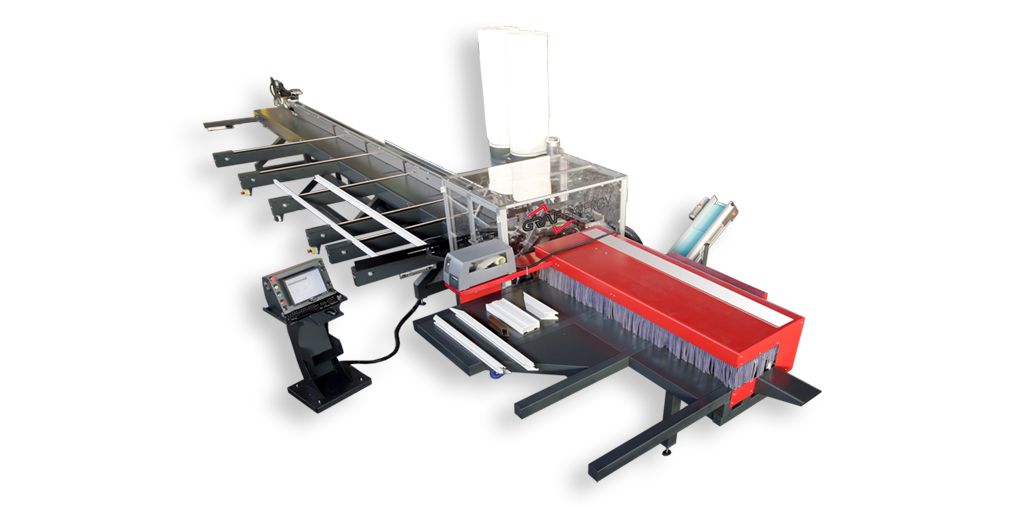

CUT 500

Compact and versatile automatic CNC cutting centre

Quick, precise, and fully automatic cutting, even in tight spaces.

Perfect for:

- Companies looking to automate cutting with low investment

- Production lines seeking reliability and precision on every bar

- Window manufacturers working with PVC profiles, including those with gaskets

- Those wanting a compact yet complete system

- Departments aiming for digitalization and production control

Request the technical brochure now or speak with an expert.

Maximum autonomy for an optimised cut

The CUT 500 is a compact CNC cutting centre with 1 or 2 controlled axes (depending on the configuration), designed to autonomously perform all cutting operations on PVC profiles: loading, alignment, cutting, and unloading.

Thanks to an upward blade with a diameter of 500 mm, a brushless motor pusher on a rack, and advanced optimisation software, the system ensures consistent precision and smooth management of production lists.

Why choose the CUT 500?

- Compact yet complete. Takes up little space while integrating all the functions of an advanced cutting center.

- Intelligent optimization. Reduces waste thanks to GRAF Synergy software and the Fly Optimizer option.

- Guaranteed precision. Automatic alignment system to straighten bars that are not perfectly straight.

- Intuitive interface. Easy cycle management through user-friendly software menus.

- High resale value. Thanks to robust construction and state-of-the-art technologies.

Product Details

Quick and clean cuts at -45° / 90° / +45° on PVC profiles, including those with seals, thanks to the high-precision upward blade.

The process is fully automated: loading bars, pushing, cutting, and unloading.

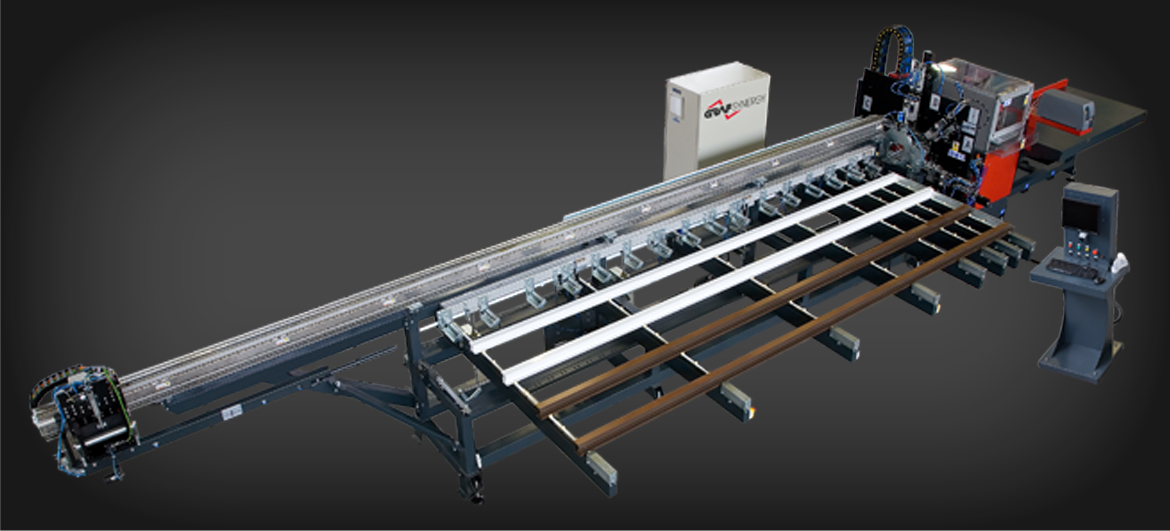

Dimensions

Length: 13,000 mm

Width: 2,800 mm

Height: 2,000 mm

Weight: 2,000 kg

Performance

Up to 300 windows in 8 hours (1 leaf)

Strongly required operators: 1

power supply and Consumption

Installed power: 7 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption: 200 Nl/min

Workable profiles

Length: 500 to 6,500 mm (optional from 400 mm)

Width: 40 to 130 mm

Height: 40 to 135 mm

Optional features and available configurations

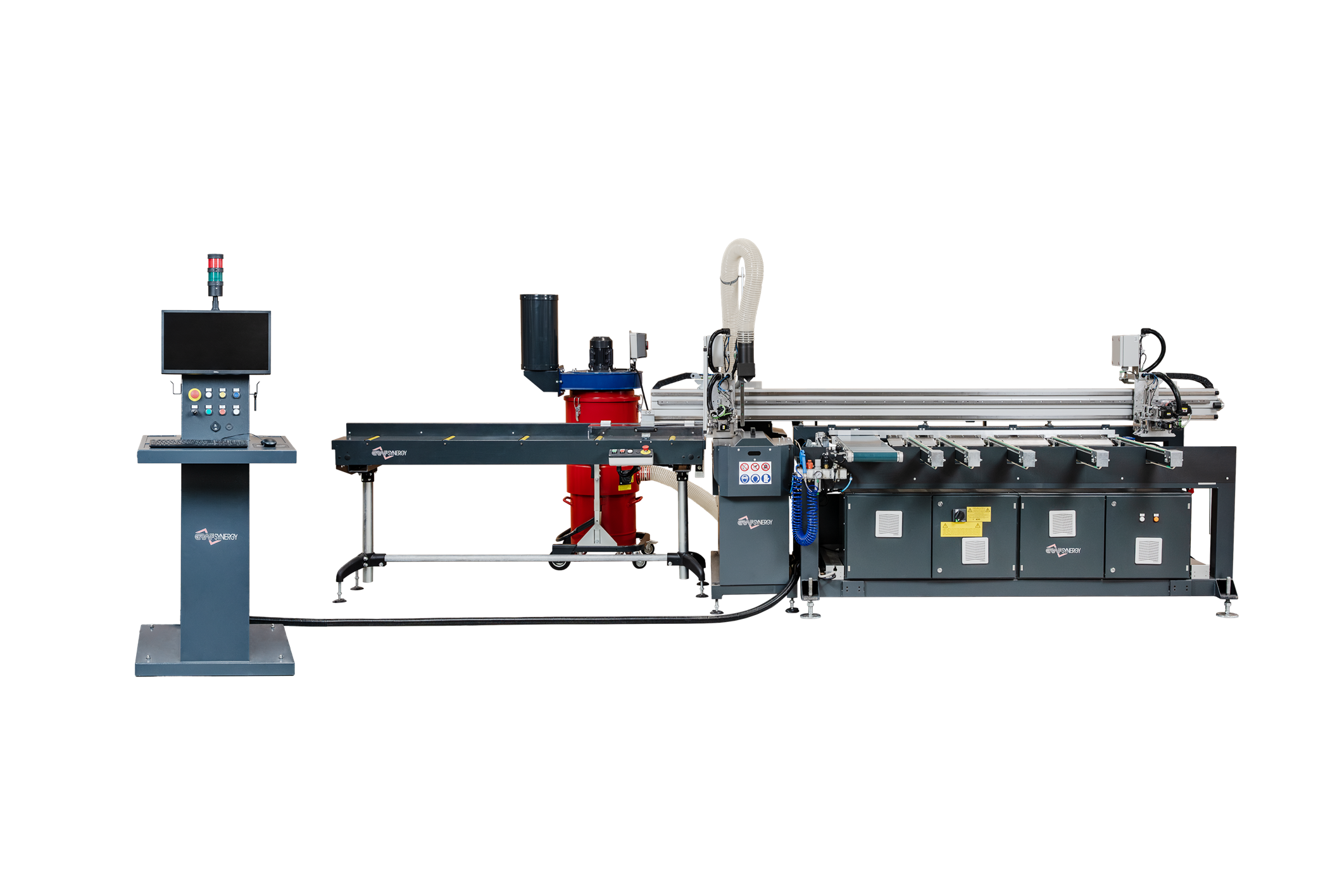

The CUT 500 can be equipped with various accessories to meet specific production needs.

- Fly Optimizer: automatic reuse of scrap

- Ø 550 mm blade with clamp kit for profiles up to 180 mm

- Brushless motor for blade rotation at intermediate angles

- Manual labeling machine

- Sensors for profile width and height control

- Horizontal clamp system for sections up to 230 mm

- Chip conveyor and two-bag dust extractor

- Extended unloading table

- Preparation for connection to 1 or 2 ASG-E units

- Bar loading system for 400 to 700 mm bars

Accessible technology and digital control

The CUT 500 management software allows for complete control of the production cycle and optimisation of lists. The system is ready for the digitalisation of the production department, providing efficiency, cost savings, and traceability.

Make profile cutting a smooth and automated process: contact us now for a demo of the CUT 500.