CUT 3B

3-Blade CNC Cutting Center for PVC Windows

Maximum productivity and precision in a single industrial cutting machine

Perfect for:

- Window manufacturers producing up to 500 windows per day

- Those who want to optimize every bar cut with advanced software

- Production departments seeking speed without compromising quality

- Companies working with profiles featuring complex or non-standard sections

- Those aiming for full automation of the cutting cycle

Request the technical brochure now or speak with an expert

The power of three synchronized blades for continuous and precise cuts

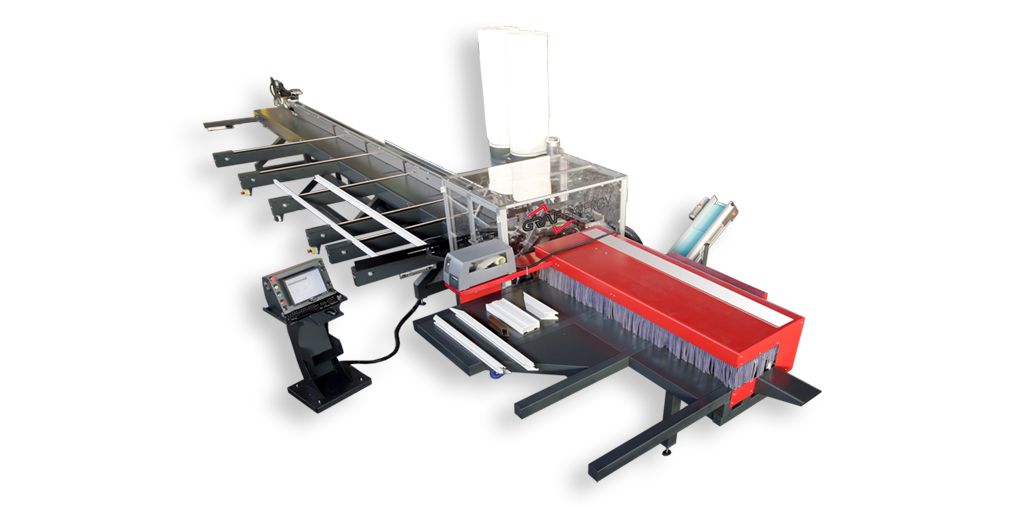

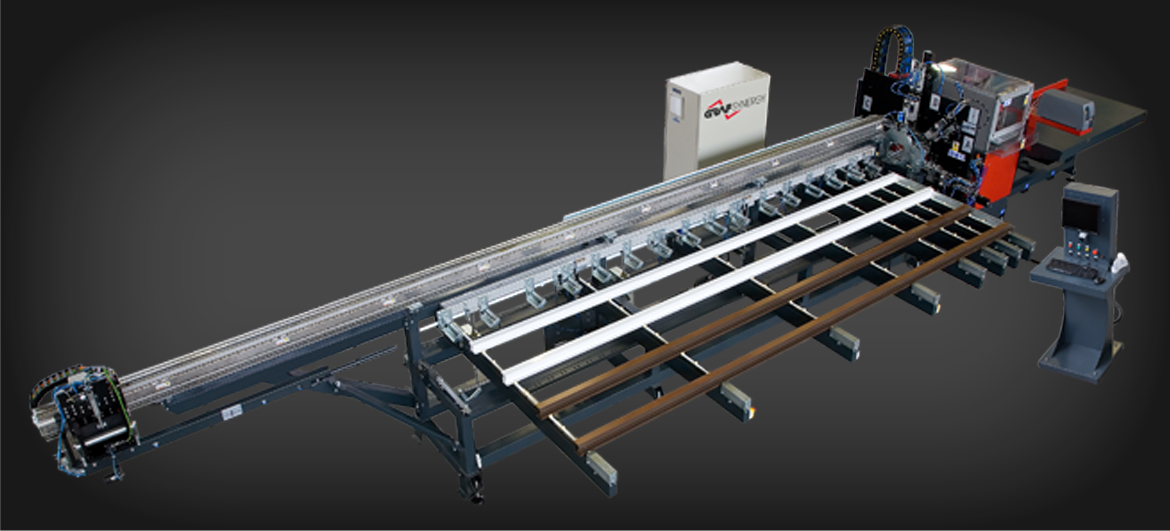

The CUT 3B is a 6-axis CNC cutting center designed to ensure the highest levels of productivity in processing PVC profiles, including those with gaskets.

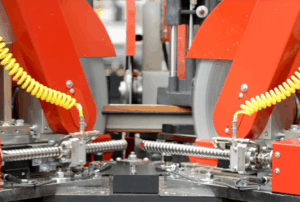

Equipped with a cutting module featuring three independent and synchronized Ø 550 mm blades, it guarantees precise cuts at -45° / 90° / +45°.

The system consists of an automatic loading magazine (up to 8 bars) with a CNC clamp powered by linear motors and hundredth-millimeter position reading.

The unloading module is motorized with belt conveyors, equipped with a safety photocell, and has a capacity of up to 15/20 pieces.

Why choose the CUT 3B

- Extreme speed and total synchronization. Three independent blades driven by brushless motors for a fast, continuous cutting cycle.

- Advanced precision on every profile. Automatic bar alignment system and CNC clamp with hundredth-millimeter reading on a magnetic band.

- Significant savings on every cycle. GRAF Synergy software optimizes cutting lists, reducing material waste and increasing efficiency.

- Full workflow automation. From the loading magazine to the unloading table, every phase is automated to eliminate downtime and delays.

- User-friendly and customizable interface. The system is designed for intuitive, fast use, with options for customization and Industry 4.0 integration.

Product Details

The CUT 3B performs fast and precise cuts on PVC profiles, including those with gaskets, with angles ranging from -45° to +45°.

The 6-axis CNC system ensures maximum control of the cutting geometry, even on complex sections.

Automatic bar linearization improves the quality of the final result.

Dimensions

Length: 16,000 mm

Width: 3,000 mm

Height: 2,400 mm

Weight: 2,500 kg

Performance

Up to 500 windows/8h (1 sash)

Operators required: 1

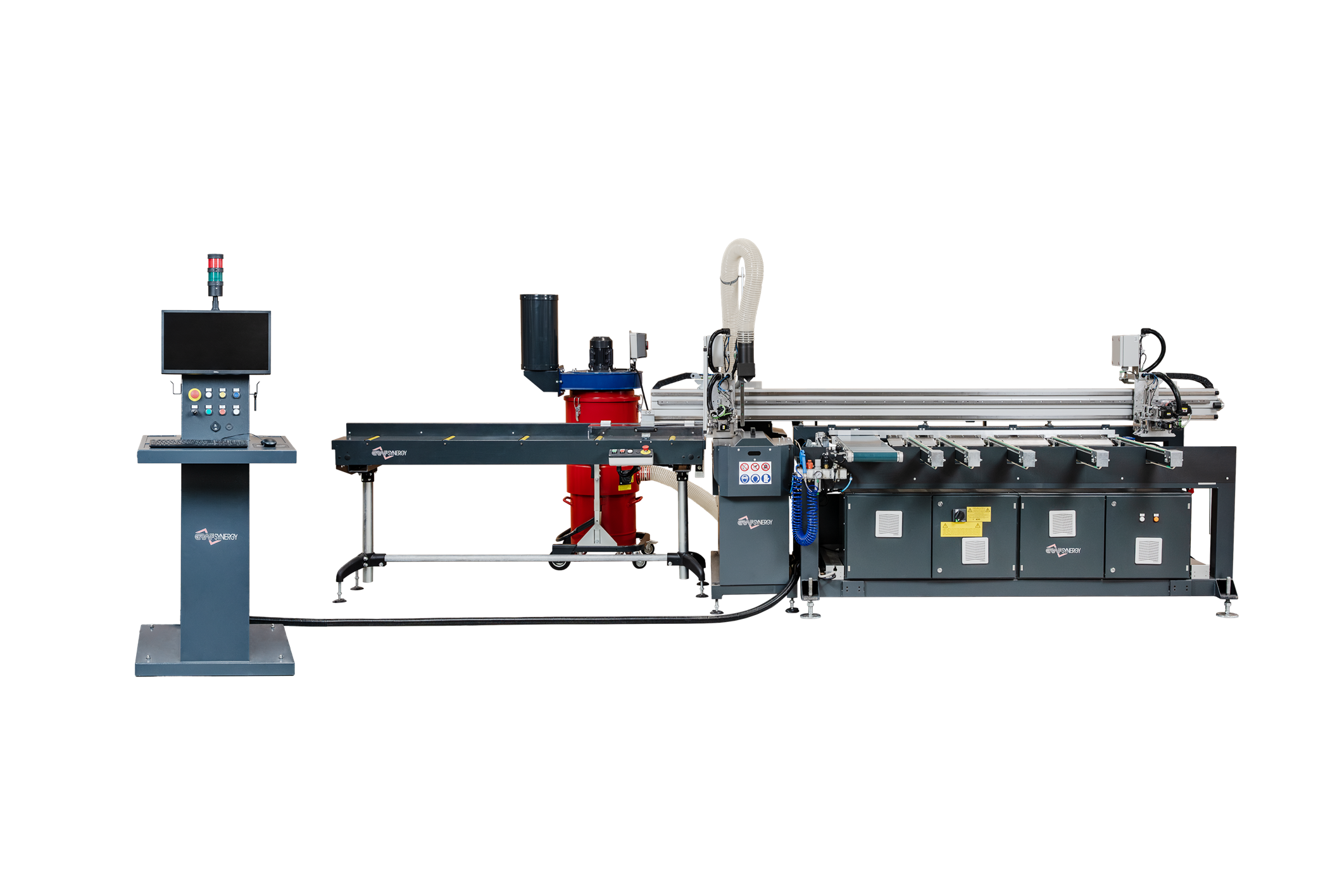

Power Supply and Consumption

Installed power: 14 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption: 200 Nl/min

Processable Profiles

Length: 700 to 6,500 mm (min. 400 mm on request)

Width: 40 to 130 mm

Height: 40 to 180 mm

Optional and Available Configurations

The cutting center can be enhanced with a range of accessories and advanced software:

Fly Optimizer: bar remnants optimization to reduce waste

STATS: production data analysis for continuous monitoring

Recover Option: reinsertion of incorrect pieces into new lists

Soundproof cabin: custom-made for noise reduction

Motorized unloading table with opposite-side output

Automatic or manual labeling machine

Profile marking laser (single or double)

Chip conveyor NRT 500 / NRT-CP

Two-bag dust extractor, 4 outlets Ø 100 (Model D4)

Preparation for connection to ASG-E screwdriving centers

Customizations on request for non-standard profiles

Advanced Software and Industry 4.0 Integration

The CUT 3B management software allows automatic import of cutting lists and cycle optimization. Integrable into smart factory systems, it supports statistical analysis, scrap reuse, error management, and customization for different profile types.

Maximize every bar, automate every cut: request a demo or technical consultation on the CUT 3B now.