BFB 1000 S

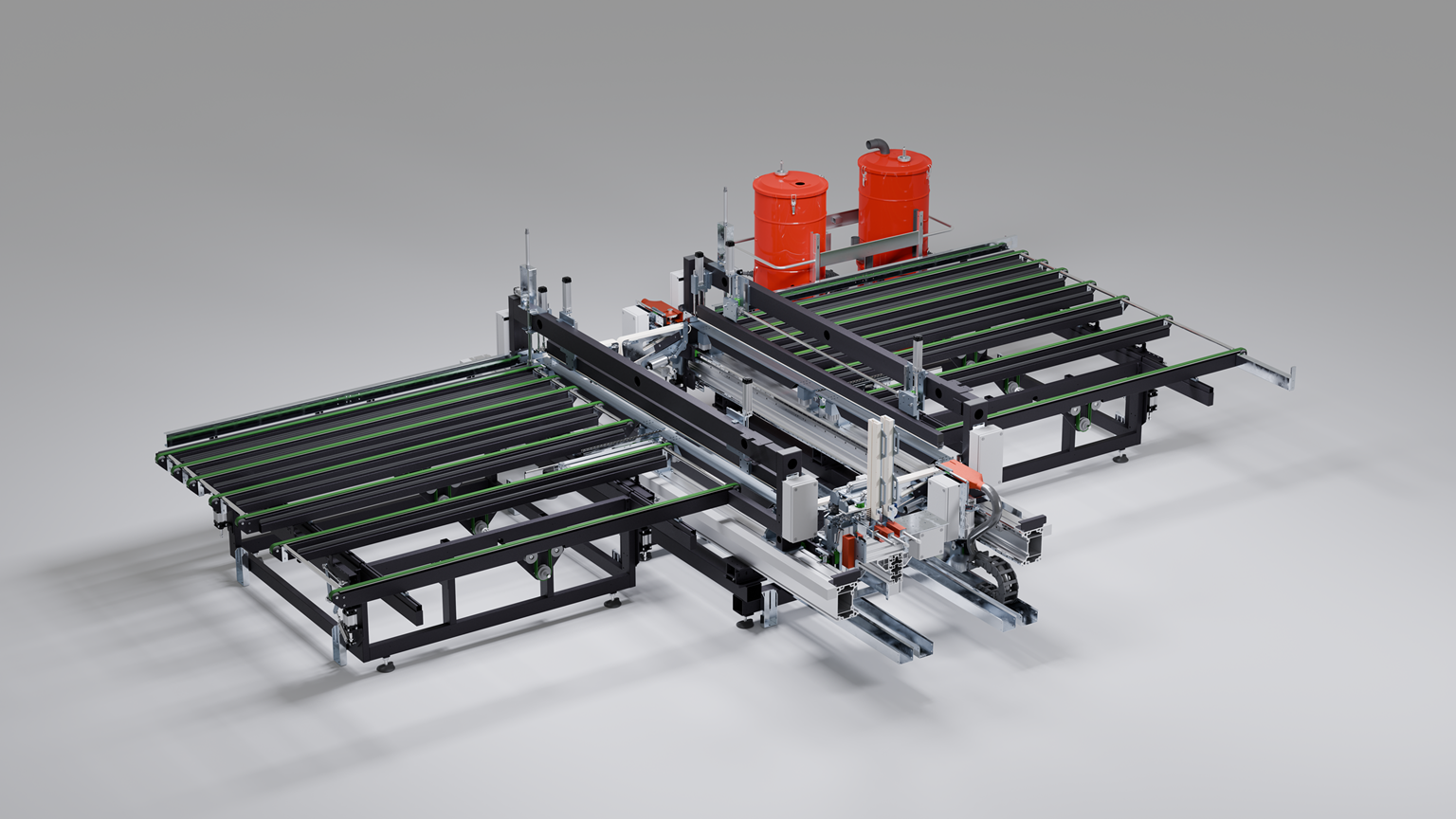

Multi-functional workbench for fitting hardware on PVC, Wood-Aluminium, and Aluminium frames.

Maximum efficiency in hardware assembly: precise, versatile, intuitive.

Perfect if you want…

- Reduce the installation time of hardware on any fixture.

- Accurately drill hinge holes, handle holes, and make Italian-style cuts.

- Working in ergonomics thanks to the tilt of the work surface

- Avoid scratches and wear on the profiles during processing.

- Integrate specific options to enhance efficiency and productivity.

Request the technical brochure now or speak with an expert.

Maximum efficiency in hardware assembly: precise, versatile, intuitive

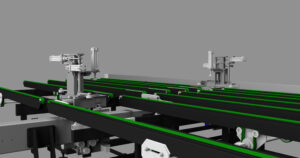

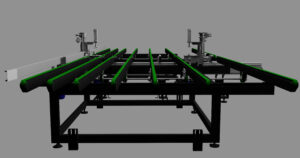

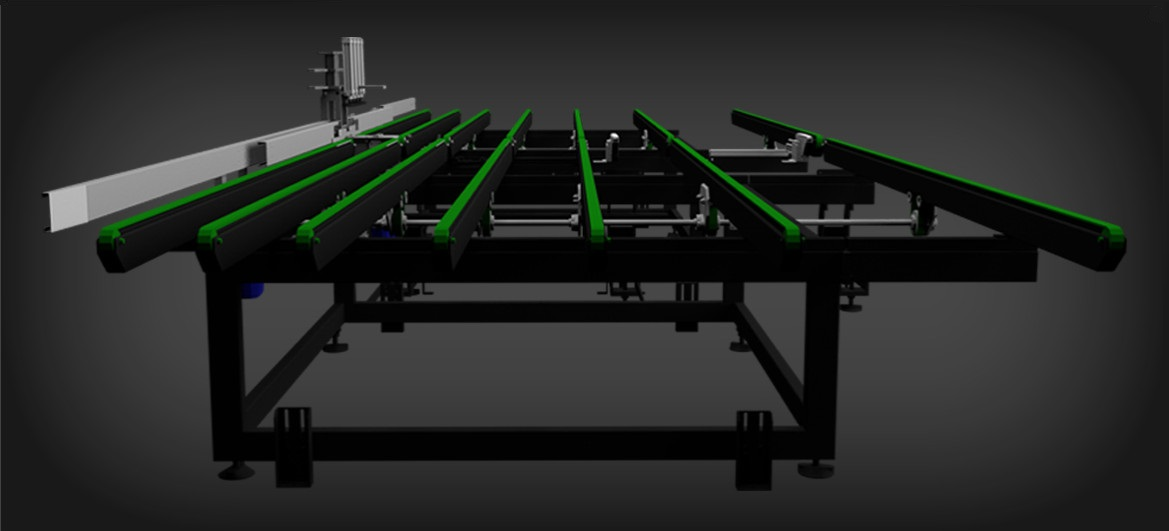

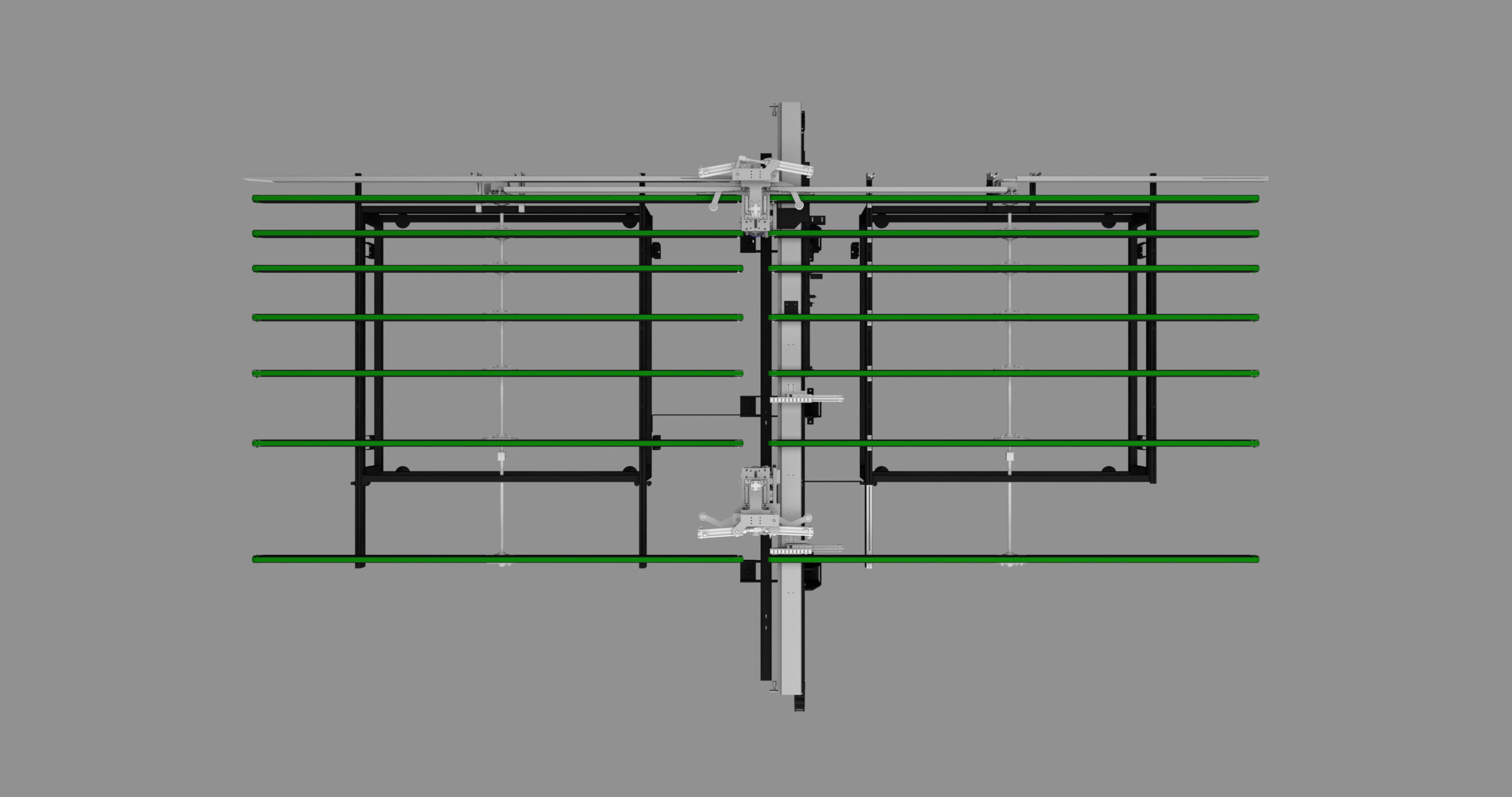

The BFB 1000 S is the multifunctional assembly bench by GRAF Synergy, designed to optimise the complete assembly of perimeter hardware on PVC, Aluminium, and Wood-Aluminium frames. Thanks to its robust steel structure, pneumatic locking of the door leaf, and a scratch-resistant work surface, it enables fast, safe, and repeatable operations.

The workbench features an adjustable pneumatic tilt from 0° to -14°, a direct measurement system for cutting tools and equipment on linear guides with ball recirculation, ensuring high precision in all operations: hinge holes, handle holes, and Italian-style cuts. Customisable with numerous options, it is perfectly suited for both craft workshops and industrial settings.

5 reasons to choose BFB 1000 S

- Maximum operational versatility. Suitable for PVC, Aluminium, and Wood-Aluminium frames, with configurable tools for every production requirement.

- Quick and error-free assembly. Pneumatic locking, reinforced rotary stops, and high-precision linear guides for repeatable results.

- Pneumatically adjustable tilt. Adjustment from 0° to -14° to enhance ergonomics and accessibility during assembly.

- Sturdy structure and scratch-resistant surface. Welded bar top coated with wear-resistant material, perfect for intensive work.

- Compact yet highly efficient. At just 3.27 metres in length, it delivers high performance even in limited production spaces.

Product Details

The BFB 1000 S performs all the necessary operations for the installation of perimeter hardware quickly and accurately.

Dimensions

Length: 3.275 mm

Width: 1,670 mm

Height (adjustable): 920 ÷ 1,020 mm

Weight: 380 Kg

Performance

Operators required: 1

Operation: Assisted manual

Usable frame sizes:

Min: 400 x 400 mm

Max: 2.500 x 2.500 mm

power supply and Consumption

Installed power: 0.2 kW

Voltage: 230 V (only with glass stop measurement kit)

Minimum operating pressure: 7 bar

Air consumption per cycle: 14 Nl/min

Supported features and processes

- Three-point handle drilling

- Hinge fixing holes, both vertical and angled

- Tool Cutting (Cremonese)

- Adjustment of position and spacing of the holes

Optional features and available configurations

To meet every production requirement, the workbench can be equipped with:

- Hydraulic Pneumatic Punching Machine for cutting tools

- Automatic screwdrivers with laser pointer (manual or automatic lifting)

- Two-Bit Drilling Unit for Hinges

- Integrable Tool Warehouse

- Glazing measurement kit

Request a personalised consultation or demo

Discover how the BFB 1000 S bench can enhance your assembly operations. Contact our experts today for a detailed brochure or a tailored quote.