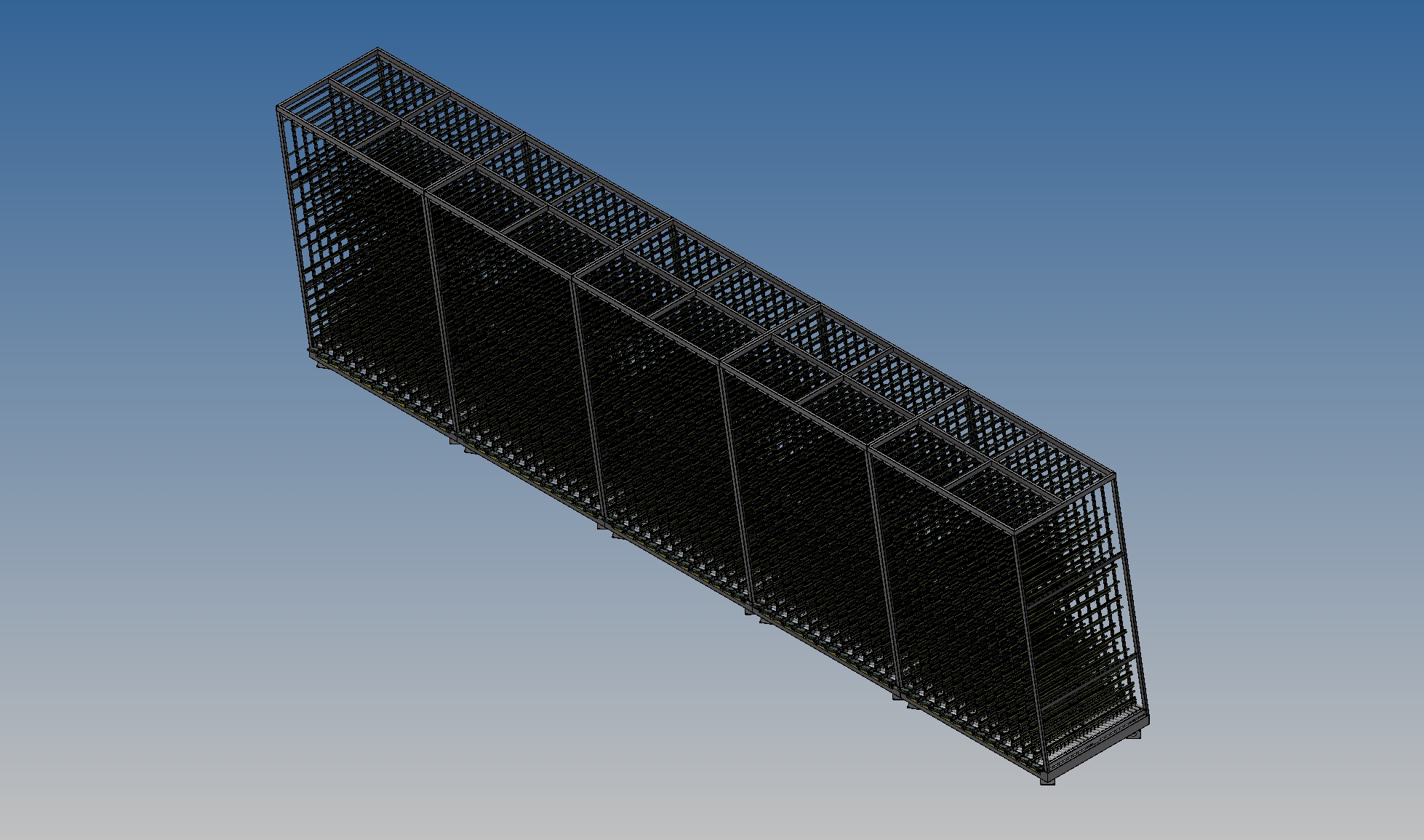

004NV

Motorised Vertical Shuttle for Glazing and Assembly Lines

Maximum speed, minimum complexity

Perfect if:

- Automate the vertical movement of window frames.

- Minimise clutter while maintaining efficiency.

- Optimise the workflow between glazing and hardware installation.

- Minimise maintenance with a simple structure.

- Enhancing operational safety during transportation

- Easily integrate the system into existing layouts.

Request the technical brochure now or speak with an expert.

Maximum speed, minimum complexity

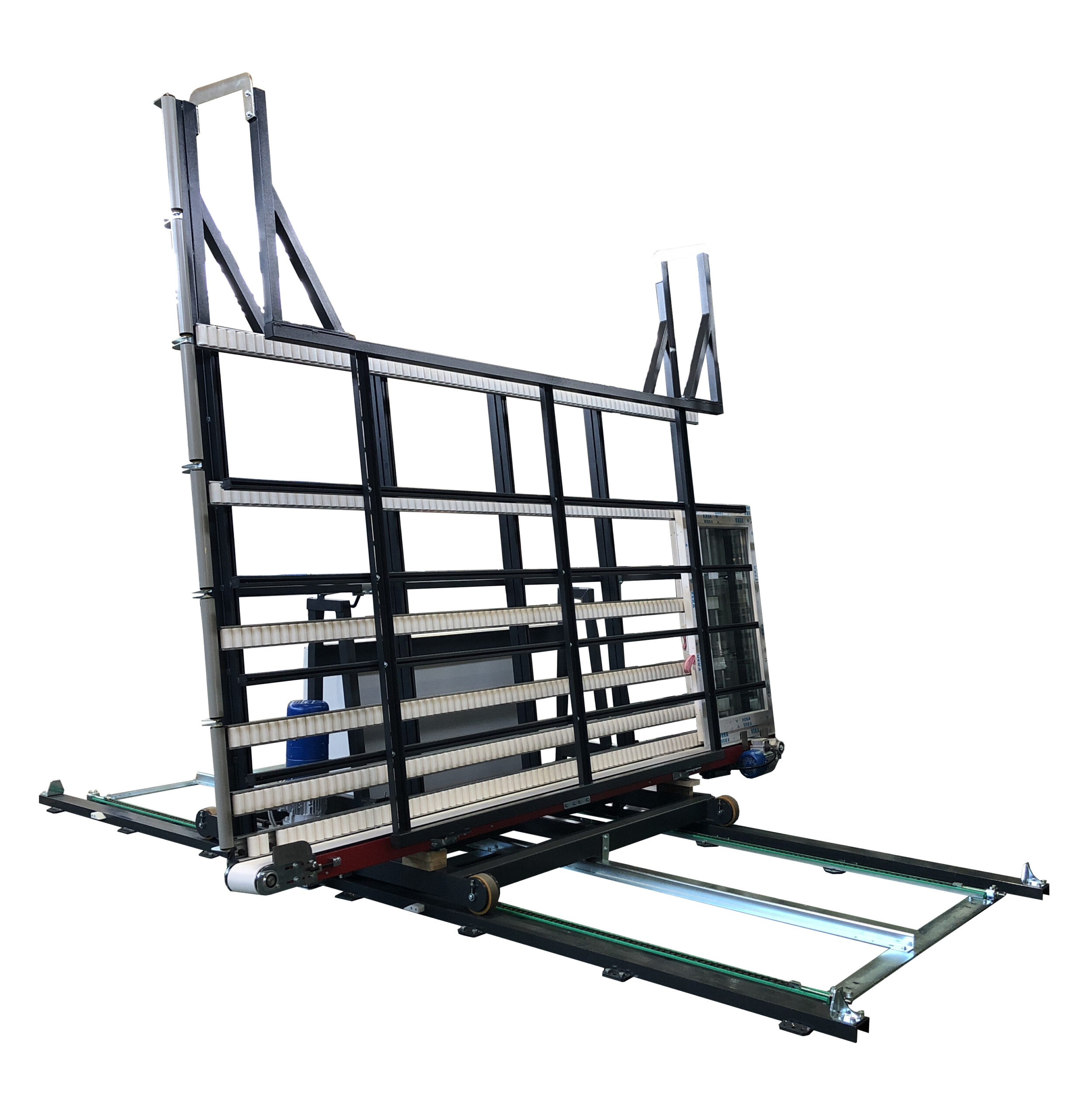

The 004NV shuttle is a high-performance solution for the vertical handling of single or paired panels and frames within automated systems. Designed to optimise the transfer of elements between glazing and assembly stations, it combines a compact structure with a high mission speed of up to 2 m/s, thanks to its brushless system with crown/chain transmission.

Its fixed inclination of 8° ensures load stability during transport, while the simplified design reduces management and maintenance costs.

5 Reasons to Choose 004NV

- Superior speed in confined spaces. Brushless system with direct mechanical transmission that allows for rapid and precise movements (up to 2 m/sec).

- Always Active Safety. Front anti-fall protections and vertical side rollers ensure a safe passage even in the event of an emergency stop.

- Low operating costs. Essential mechanical design and efficient motors for economical and sustainable management.

- Smooth and Stable Movement. A surface with caster wheels and an 8° inclined structure for optimal support of the elements.

- Maximum format adaptability. Available in various versions (up to 5,000 mm in square length) to meet every production requirement.

Product Details

004NV is designed to safely handle doors and frames within automated lines, ensuring stability and precision.

Dimensions

Length: 1,900 mm

Width: 3,600 mm

Height: 3,000 mm

Weight: 900 Kg

Performance

Average cycle time (loading + transport + unloading): 30 sec*

Translation Speed: up to 2 m/s

Operators required: 1

(depends on the length of the line)

power supply and consumption

Installed power: 9 kW

Voltage: 400 V

Air consumption per cycle: 50 NI/min

Operating pressure: 7 bar

Manageable profiles (frame sizes)

Maximum length: 1,400 mm

Maximum width: 2,800 mm

Maximum thickness: 130 mm

Supported features and processes

- Conveyor belt with inverter for dynamic adjustment

- High-capacity surface with crazy wheels

- 4 wheels on floor tracks for linear movement

- Vertical rollers for centring

- Front protection systems for fall prevention

Optional features and available configurations

The 002NV is highly customizable according to production layout and handling requirements. Among the options available:

- Rack and pinion system for transmitting motion to the warehouse conveyors.

- Integrated handling straps for the panel

- Alternative versions of useful formats:

- 004NV36: 2.800 x 3.600 mm

- 004NV40: 3.200 x 4.000 mm

- 004NV50: 3.200 x 5.000 mm

These variants make the shuttle suitable for complex systems or non-standard handling requirements.

TECHNOLOGY AND AUTOMATION

Thanks to its optimised mechanical architecture, the 004NV offers a robust and straightforward solution for automated vertical handling. The asynchronous motors with inverters allow for precise speed adjustments, making the system compatible with Industry 4.0 standards. The system can be integrated with line management systems and supervisory software for real-time traceability and production coordination.

Contact us to find out if the 004NV is the right solution for your production.