001SP

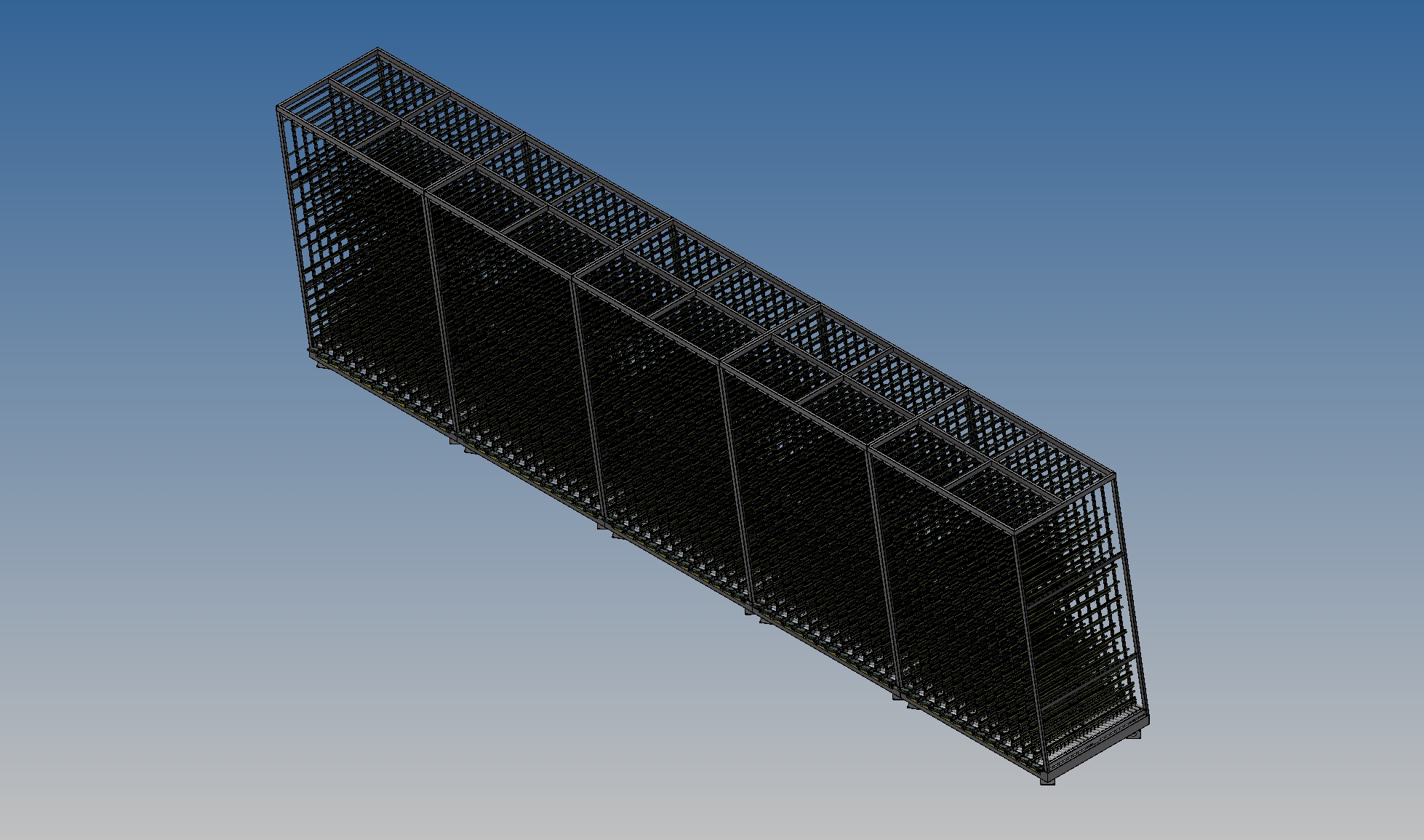

Roller Conveyor with Vertical Backrest for Logistics and Window Frame Storage

Simple, modular, essential

Perfect if:

- Integrating a roller conveyor into an automated or manual line.

- Managing finished doors and frames vertically

- Reduce costs with a simple and robust solution.

- Improving the production flow with intermediate stations

- Customise the roller step and the backrest according to the layout.

- Have a ready-to-use and easy-to-install structure.

Request the technical brochure now or speak with an expert.

Simple, modular, essential

The 001SP roller conveyor is the ideal base for any logistics line or production facility that requires the movement and orderly management of doors, frames, or finished fixtures. Thanks to its painted steel structure, vertical backrest with swivel wheels, and 200 mm rollers, it ensures stability and smooth operation with minimal footprint.

Modular and customizable, it is perfect as a collection point, transit location, or intermediate storage.

5 reasons to choose 001SP

- Simple, efficient, cost-effective structure. Made from welded and painted steel, it ensures long-lasting durability and requires no maintenance.

- Total modularity. Available in lengths from 1 to 3 metres, with heights from 2 to 3 metres. Easy to adapt to your system.

- Vertical wall rack with protections. Equipped with 5 slats featuring swivel wheels and corner-saving profiles: your frames will always remain aligned and protected.

- Optional for every need. Reduced roller pitch, extra rollers of 200/500 mm, manual/automatic rotation, anti-fall system.

- Also available with motorisation. Version with rubber rollers and autonomous movement on rails: perfect for advanced systems.

Product Details

001SP is designed for the smooth movement and storage of frames, casements, or doors.

Dimensions

Length: from 1,000 to 3,000 mm*

Width: 750 mm

Height: from 2,000 to 3,000 mm*

Weight: from 70 to 140 kg*

Adapt this content naturally and fluently into English. Content: (*based on the chosen version)

Performance

Operators required: 1

Working length: 2800 mm

Working width of the frame: 1500 mm

power supply and Consumption

Installed power: not required

Nutrition: not provided

Air consumption: not applicable

Operating pressure: not required

Supported features and processes

- 200 mm steel roller base

- Vertical wall bars with swivel wheels

- Corner edge protectors

Optional available

- Reduction of the pitch between rollers to 100 mm

- Manual/automatic rotation kit for the wall bars

- Railway translation kit

- Fall protection system for frames

- Additional roller with a diameter of 200 or 500 mm

Available variants:

- 001SP30: 3.000 x 2.800 mm

- 001SP36: 3.600 x 2.800 mm

- 001SP40: 4.000 x 2.800 mm

- 001SP50: 5.000 x 2.800 mm

- Motorised version with rubber rollers and a 3m track

Technology and Automation

The basic version is completely passive and does not require power. However, in the motorised version, the 001SP can be integrated into automated lines with autonomous movement and logical controls. It is also an ideal solution for Industry 4.0 lines that require dynamic buffers or motorised intermediate stations.

Contact us to find out if the 001SP is the right solution for your production.