001NV

Horizontal Sliding Table for Multi-Line Production Flows

Logistics automation for faster welding without bottlenecks

Perfect if:

- Manage multiple welding lines simultaneously and are looking for a system to unify their flows.

- Do you want to eliminate manual handling of the fixtures after welding?

- You need to automate your internal logistics to save time and improve accuracy.

- You work with large frames and doors that require safe and stable handling.

- You want to keep the production layout tidy and streamlined, even in complex spaces.

- Do you want to prepare your line for a transition to a fully automated system?

Request the technical brochure now or speak with an expert.

Logistics automation for faster welding and no bottlenecks

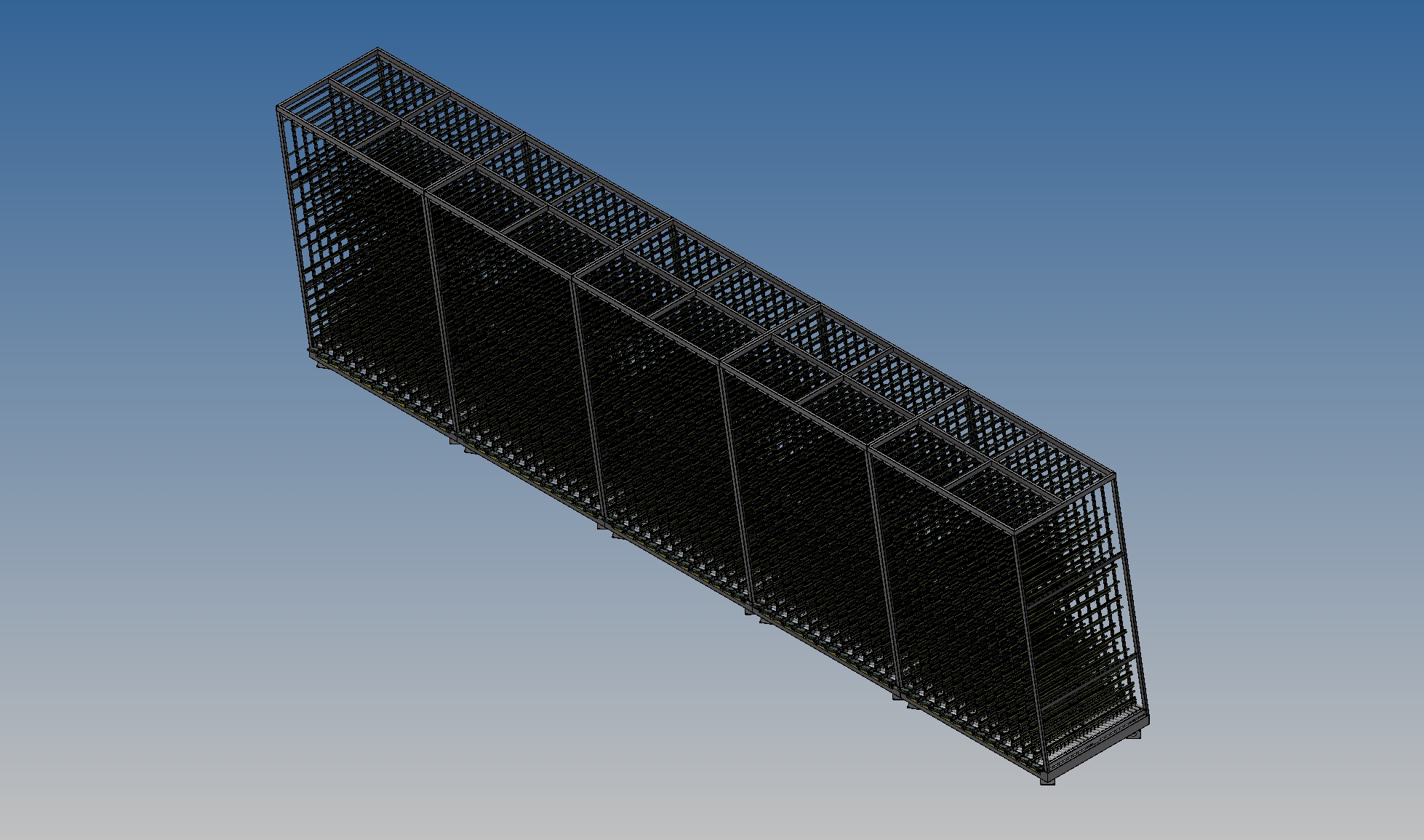

The horizontal transfer table 001NV is the automated solution designed by Graf Synergy to optimise the handling of welded frames. Thanks to its robust structure and rail-based transfer system, it allows for the collection and sorting of components from multiple welding lines, such as doors and frames, directing them to the next workstations without manual intervention. It is ideal for production environments aiming to increase productivity by eliminating downtime and reducing the risk of damage to frames during transport.

5 reasons to choose the Sliding Horizontal Table 001NV

- Multi-line flow automation. It allows for the collection and diversion of welded frames from two or more welding machines, optimising productivity and reducing the need for personnel in internal logistics.

- Sturdy and long-lasting structure. Built entirely from welded and powder-coated steel, it ensures maximum stability even under heavy loads and prolonged use.

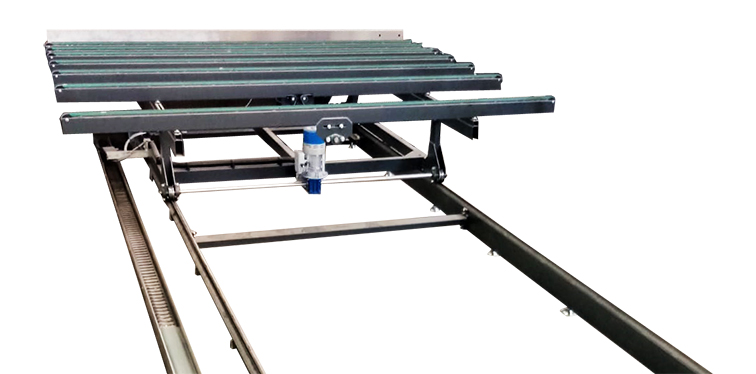

- Smooth and precise movement. Equipped with 4 high-capacity steel wheels, it glides on dedicated tracks thanks to a system connected to the motor shaft. The motorised belt platform ensures safe transfer of the panels.

- Destination Flexibility. The system allows for routing to different workstations based on the layout or the type of processing required.

- Scalability with brushless motors. Upon request, the table can be equipped with brushless motorised belts, ideal for high productivity systems with more than 2 users.

Product Details

The 001NV is designed to facilitate a smooth transition between welding phases and subsequent processing. The system is built to withstand constant stress and ensure reliability during continuous cycles.

Dimensions

Length: 3,600 mm

Width: 2,850 mm

Height: 955 mm

Weight: 800 Kg

power supply and Consumption

Installed power: 7 kW

Voltage: 400 V

Air consumption per cycle: –

Operating Pressure: –

Performance

Automated movement on tracks

Powered belt conveyor

Operators required: 1

Movable profiles

Maximum frame length: 3,200 mm

Maximum frame width: 2,800 mm

(Sizes depend on the connected sources)

Supported features and processes

- Automated handling of welded frames

- Sorting on dedicated tables

- Transport on powered belts

Optional available

To enhance efficiency on complex lines, the Translating Horizontal Table 001NV can be customised to meet specific needs:

- Brushless motors with independent belt for high-intensity systems

- Custom configurations for non-linear layouts or limited space

- Integrated management software (upon request)

Technology and Automation

The technological heart of the 001NV lies in its ability to integrate into complex production flows. The mechanical system, simple and robust, is designed for future connections with digital solutions and complete automation.

- Control via centralised crankshaft

- Industry 4.0 Readiness (available upon request with digital modules)

- Compatibility with CNC and PLC systems of Graf Synergy welding machines

Contact us to find out if the 001NV is the right solution for your production.