001MA

Vertical Warehouse with Induced Motion for Smart Storage

Modular, automated, always in sync

Perfect if:

- Completely eliminate manual handling of the panels.

- Create an automatic buffer between welding and assembly.

- Manage doors and frames in vertical storage with order and safety.

- Optimising workflow in continuous or asynchronous systems

- Automate the retrieval of items to the workstations.

- Integrating a warehouse with Industry 4.0 principles.

Request the technical brochure now or speak with an expert.

Modular, automated, always in sync

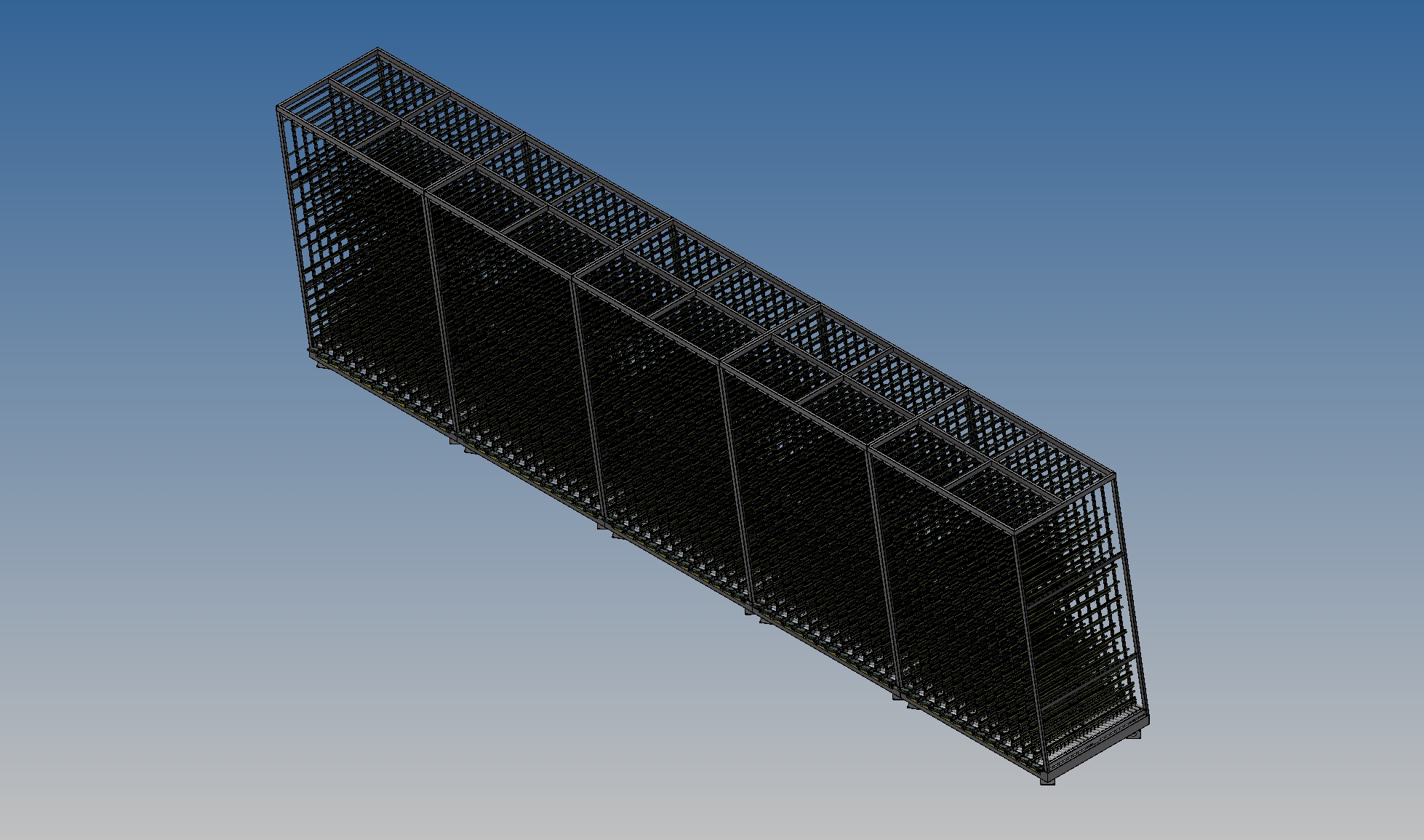

The 001MA vertical warehouse by Graf Synergy is designed to eliminate manual handling of items and create a strategic buffer between production phases. Thanks to the induced motion, each compartment can be moved directly by the shuttle through mechanical coupling, allowing for smooth and controlled movement of the panels.

With compartments 160 mm wide equipped with side rollers, backrests inclined at 8-10°, and a tilt-resistant structure, it is the ideal solution for optimising vertical space and managing storage intelligently and neatly.

5 reasons to choose 001MA

- Smart buffer for non-synchronised flows. It compensates for the lag between welding, glazing, and assembly through a modular storage system.

- Induced Motion Handling. Each compartment moves through the engagement of a gear and pinion system along with a conveyor belt, controlled by a shuttle or a dedicated motor.

- Configurable automatic recall. Programmable system for retrieving a single panel, specific position, entire order, or complete kit.

- Protection and vertical order. Inclined side rails, lateral rollers, and an anti-tipping frame ensure stability and integrity of the frames.

- Highly modular and customizable. Configurable with carpets of 160 or 200 mm, bilateral induced motion or compartments with electric gear motors.

Product Details

The vertical warehouse 001MA from Graf Synergy is designed to eliminate manual handling of items and create a strategic buffer between production phases. Thanks to the induced motion, each compartment can be moved directly by the shuttle through mechanical coupling, allowing for smooth and controlled movement of the panels.

Sizes

Length: 4,300 mm

Width: 2,400 mm

Height: 3,400 mm

Weight: 2.400 kg

Performance

Operators required: 1

Working frame length: 2800 mm

Working width: 1400 mm

Power supply

Installed power: 3 kW

Power Supply: 400 V

Air consumption: not applicable

Operating pressure: not required

Supported features and processes

- Vertical storage of doors, frames, and fittings

- Automatic retrieval of frames based on kit or location

- Mechanical coupling with shuttle for handling

Structure composed of:

- 160 mm rooms with side rollers

- Anti-tip frame in the first compartment

- Inclined vertical wall bars at 8-10°

- Arms with brushes for safe driving

Optional features and available configurations

- Compartment with a 200 mm carpet

- Induced motion on both sides of the module

- Single compartment with carpet and electric gear motor with inverter (160 or 200 mm)

These configurations allow the warehouse to be adapted for high-volume facilities and complex layouts.

Technology and Automation

The 001MA system utilises mechanical coupling between the shuttle and module via a pinion and gear to activate the induced motion. With inverter control capabilities, line supervisor management, and integration with ERP systems, it is a key component for Industry 4.0 lines. It enables predictive and just-in-time management of storage, reducing bottlenecks and increasing efficiency.

Contact us to find out if the 001MA is the right solution for your production.