Company

V-Perfect® Technology

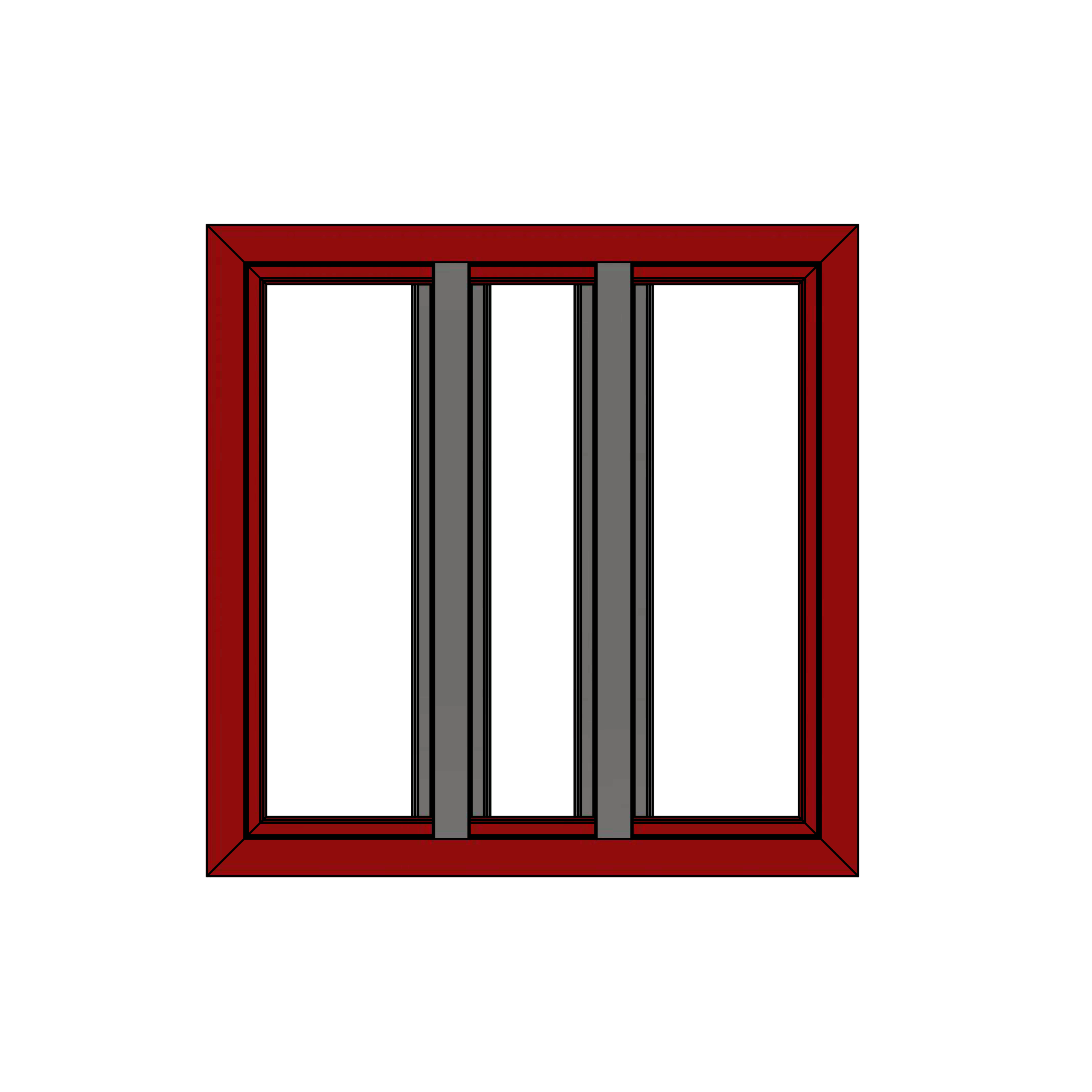

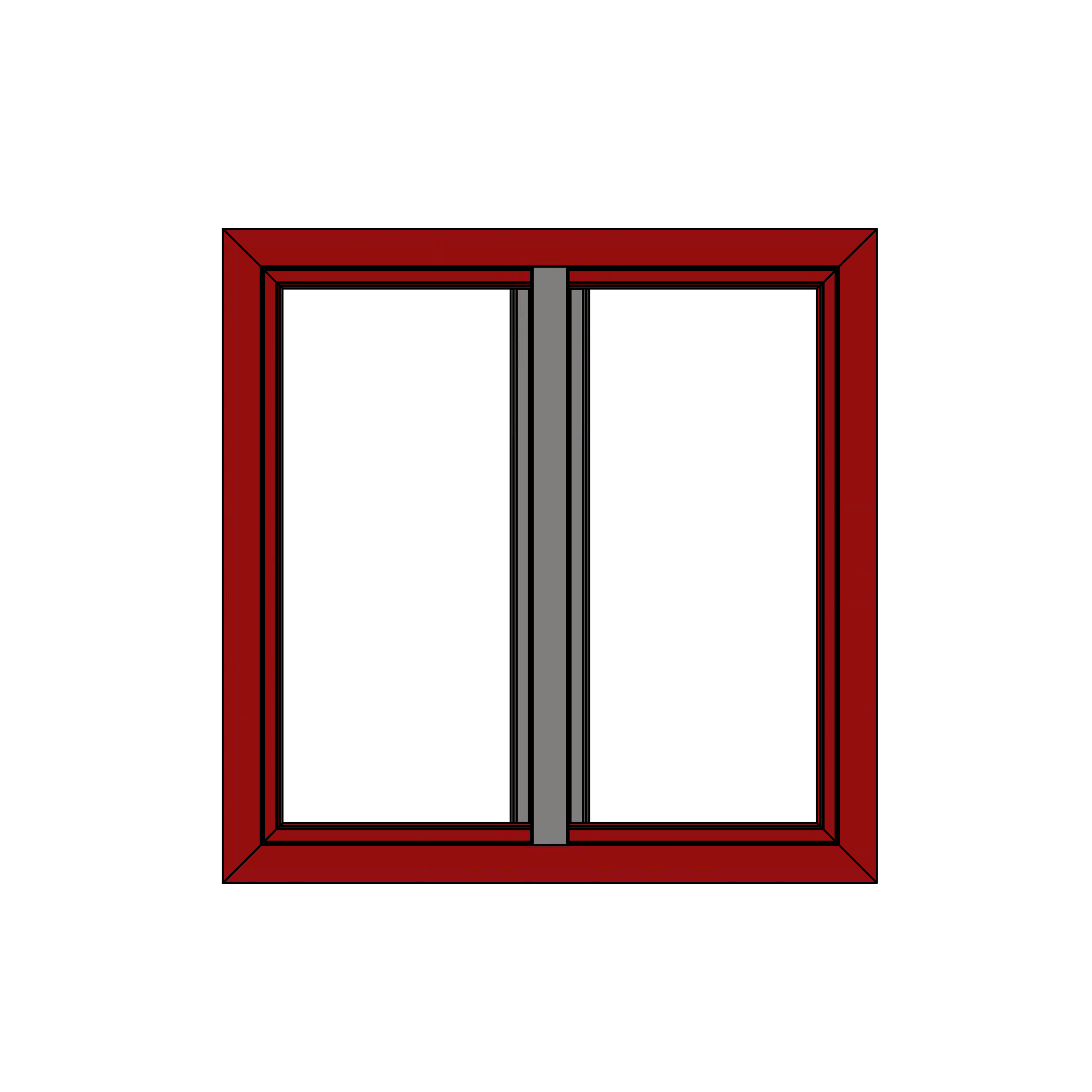

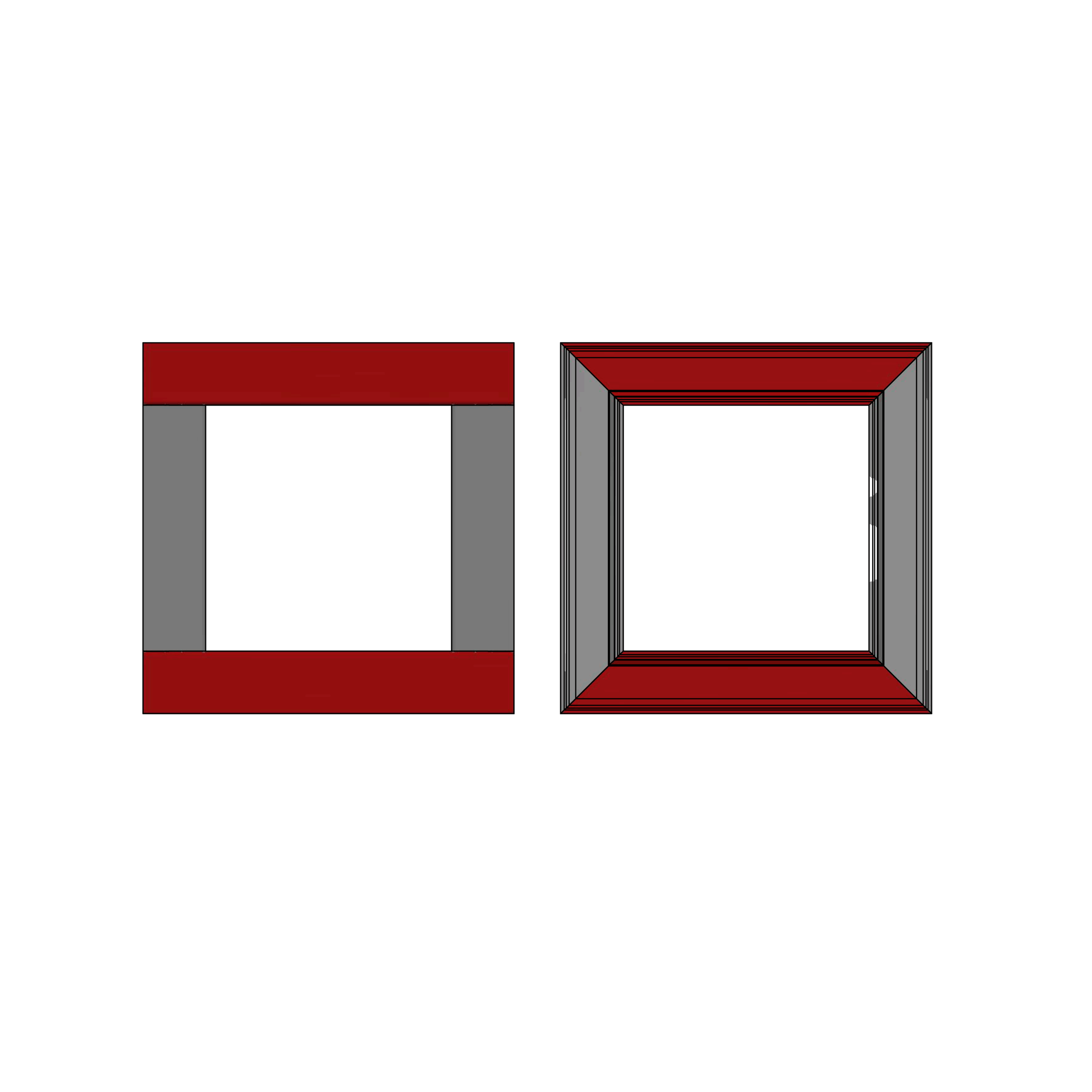

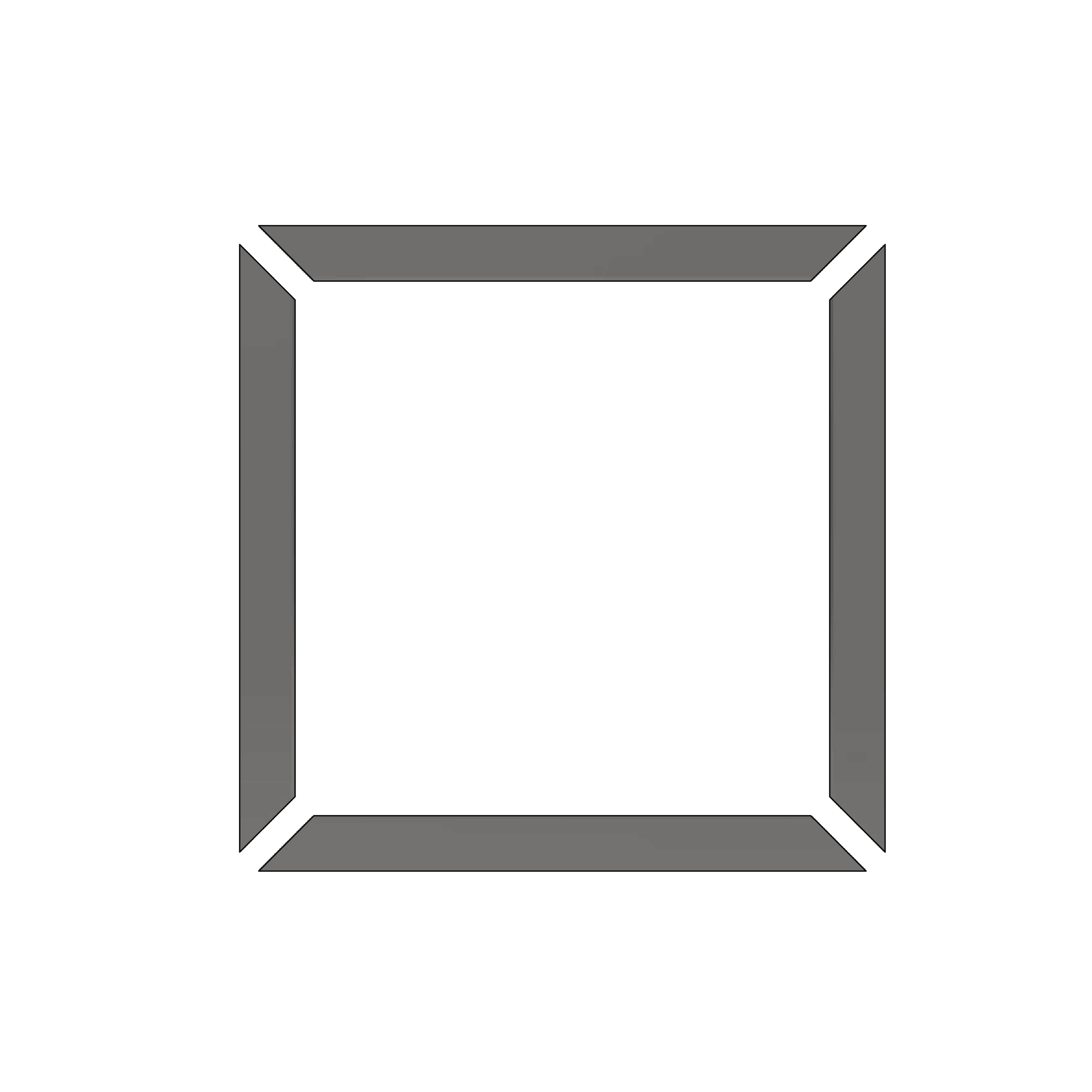

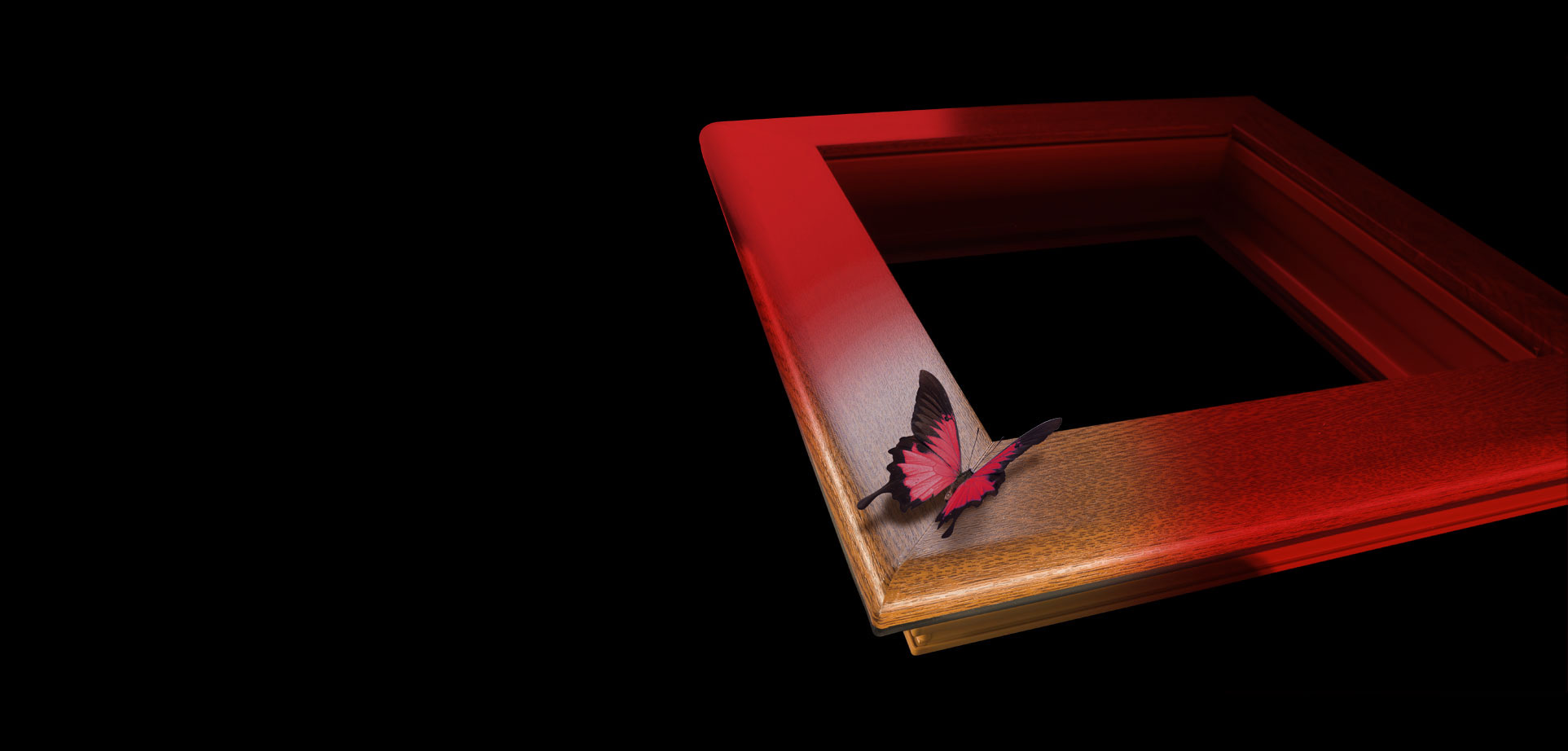

V-Perfect®: the invisible welding that transforms the aesthetics of fixtures

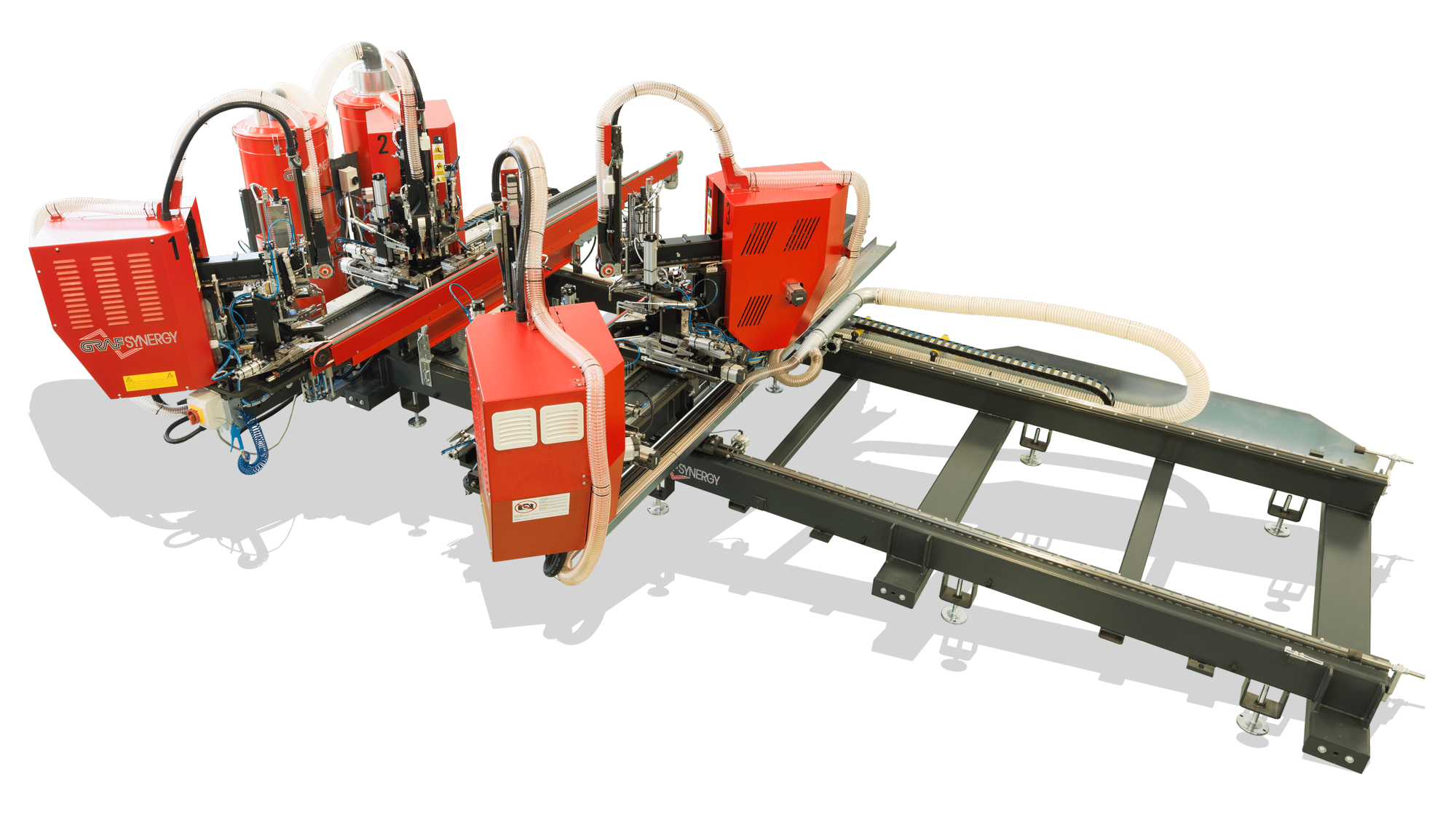

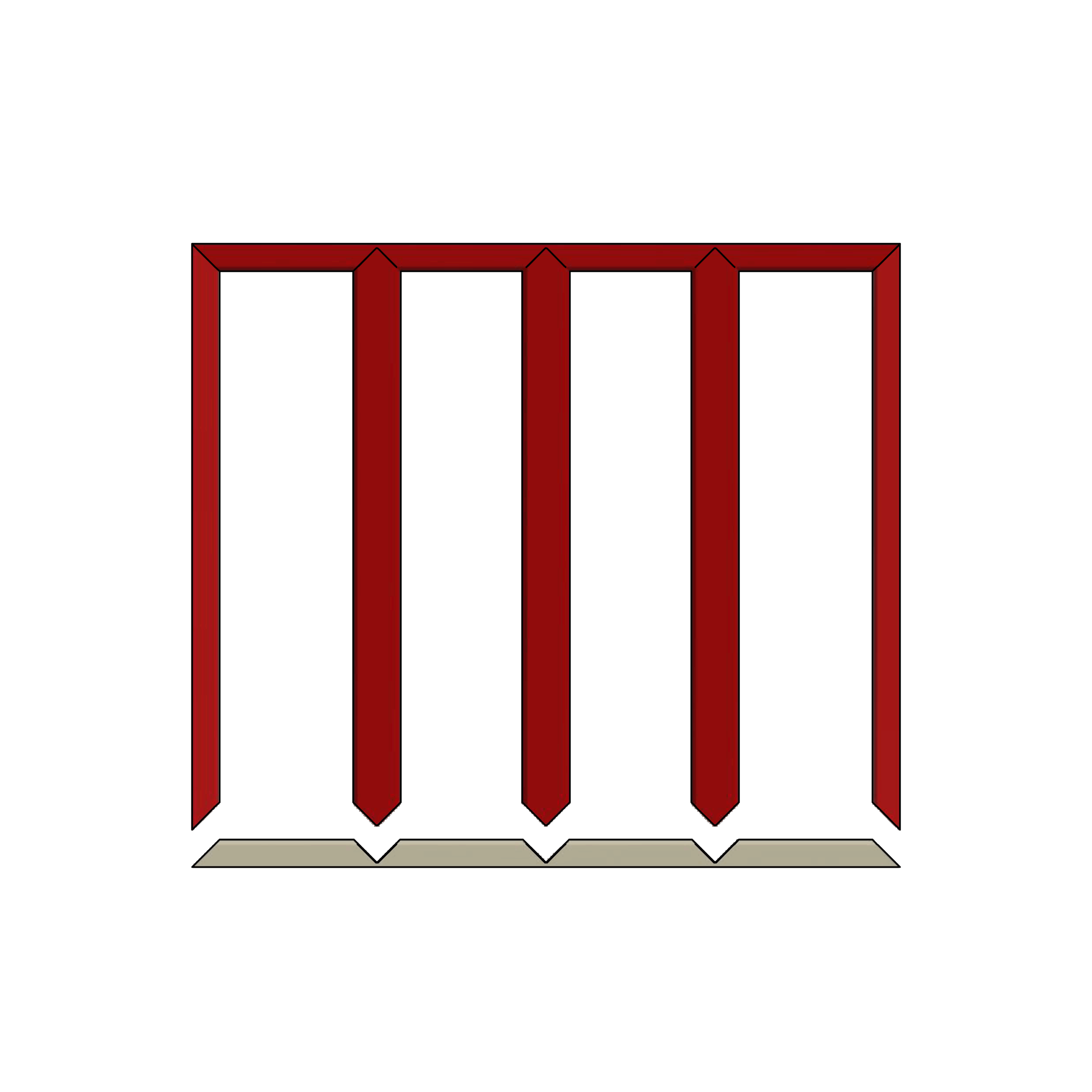

The patented V-Perfect® technology marks a turning point in the welding of PVC profiles.

Thanks to an exclusive processing system, it allows for the complete elimination of the visible edge in the corner, ensuring a flawless aesthetic finish.

With V-Perfect®, the fixture becomes a true design element, capable of meeting even the most demanding market requirements.

Materials, processes, and people: sustainability from all angles

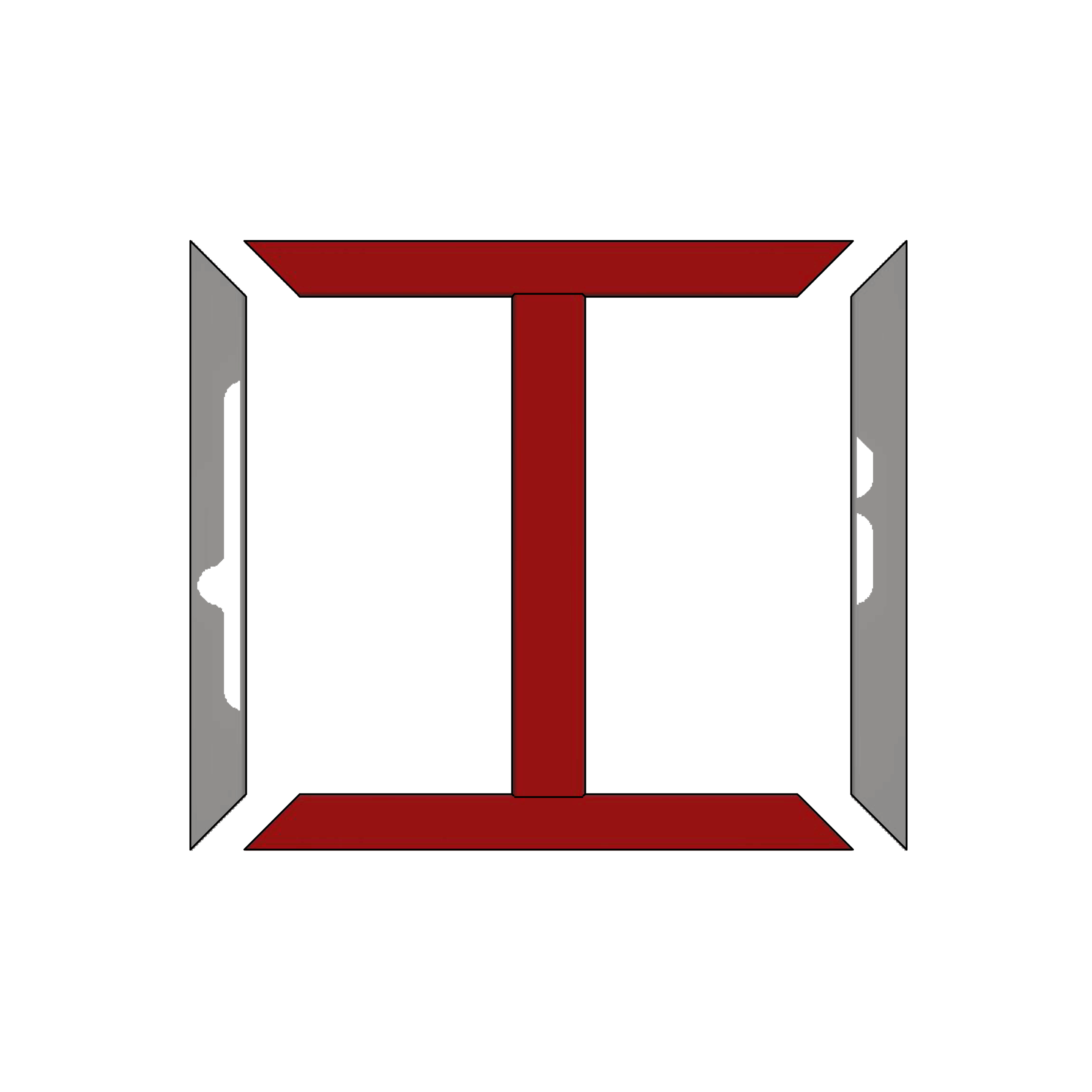

Perfect finish, reduced times: the technology that simplifies every process.

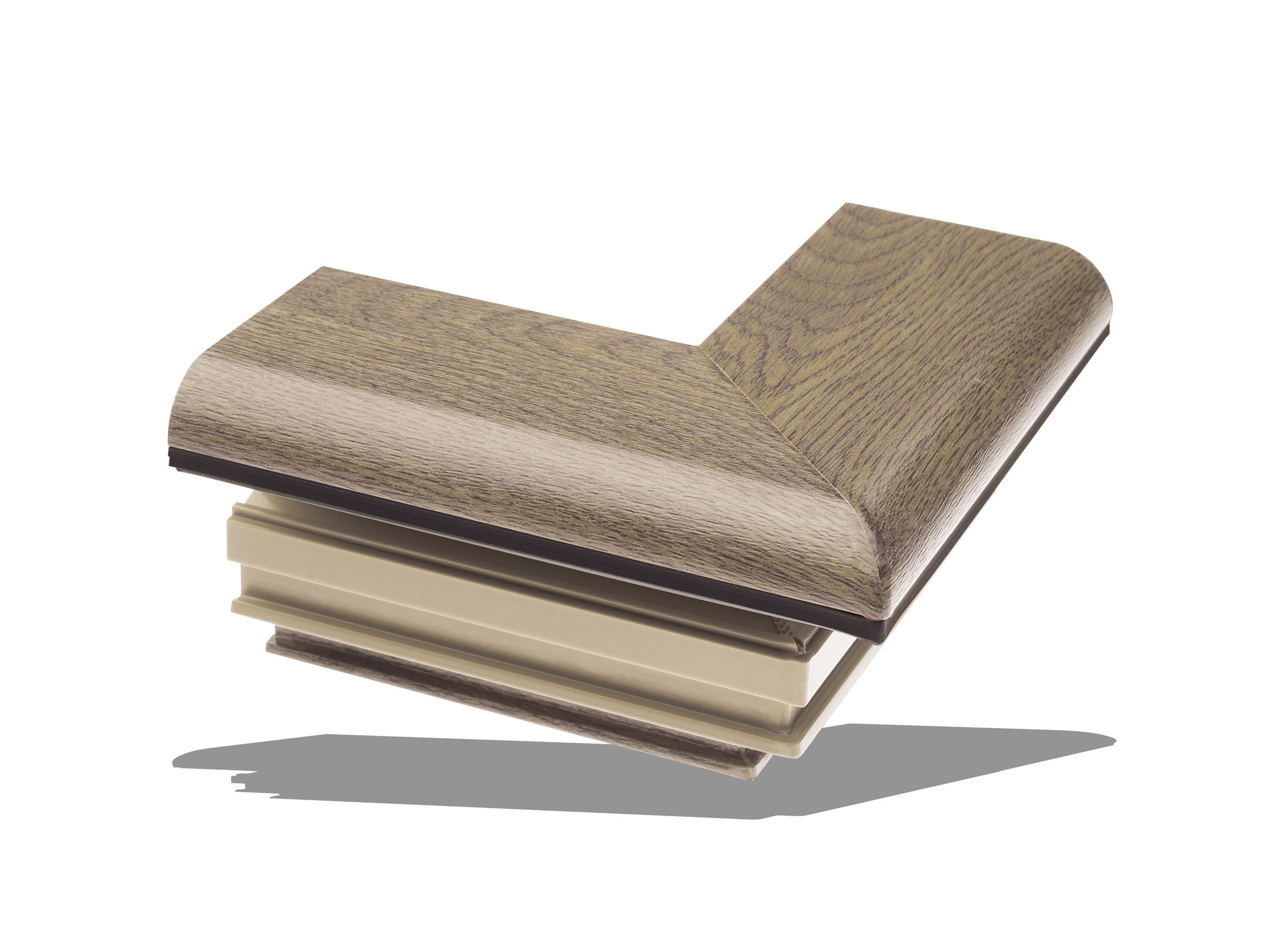

The great advantage of V-Perfect® is not only aesthetic but also functional and economical.

The perfect union of the profiles allows for the avoidance of any cleaning or finishing operations post-welding, resulting in a significant reduction in time, labour, and waste.

It is the ideal technology for those who want to optimise production processes without compromising on the quality of the results.

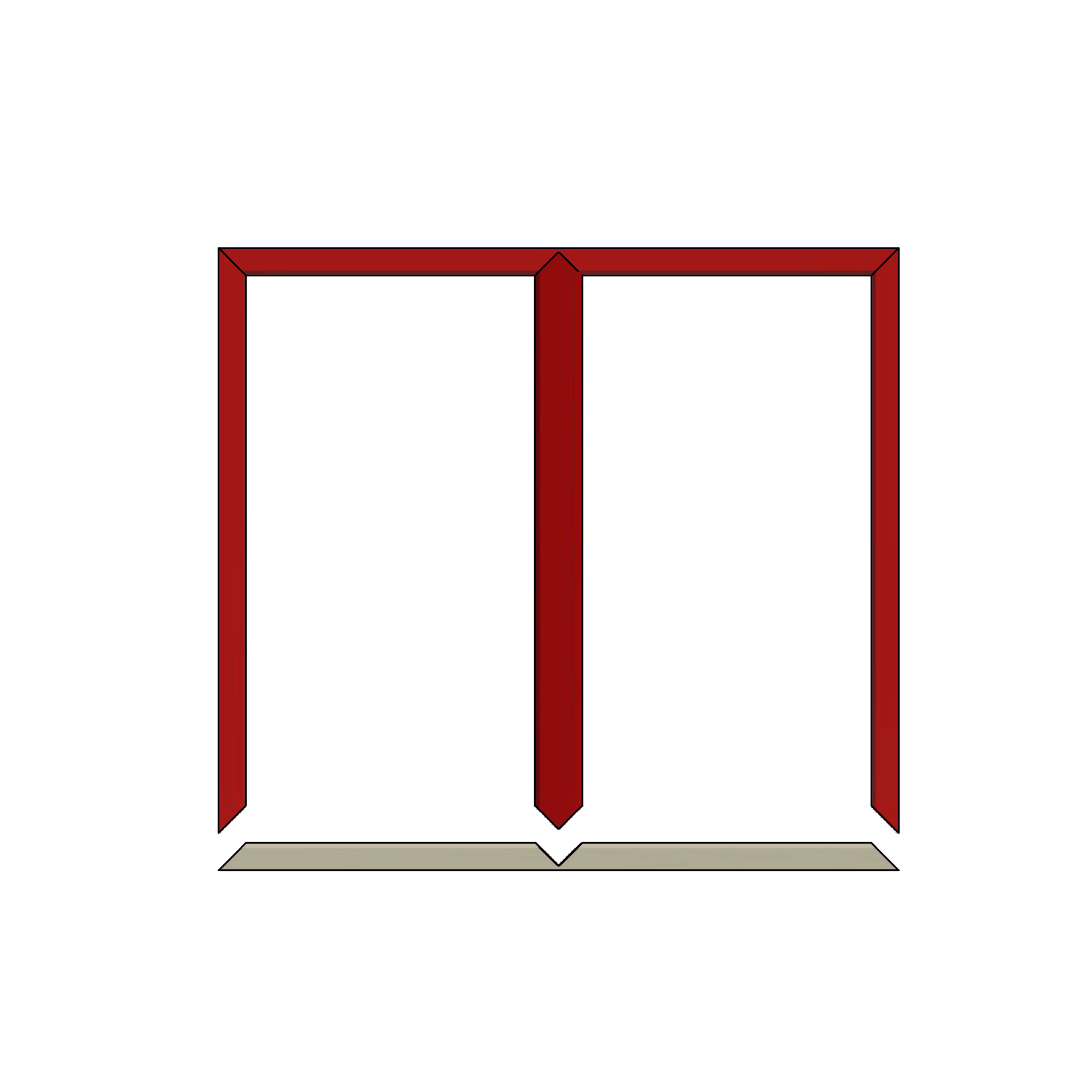

A choice that makes a difference: why more and more companies are choosing V-Perfect®

Our Research & Development department is made up of mechanical, electronic, and computer engineers who work closely with production. A cross-functional team that develops:

- V-Perfect® is already adopted by hundreds of companies worldwide as the standard for producing high-quality aesthetic fixtures.

- It represents a genuine competitive advantage: those who choose GRAF Synergy choose to stand out.

- It is compatible with most PVC profiles, including the more delicate ones, coated or with inserts made of non-weldable materials.