Company

Technology that simplifies

From the heart of Italian engineering, intelligent solutions for the future of window fittings.

Innovation is in our DNA.

For over 30 years, GRAF Synergy has been designing automation solutions for the industry, anticipating market needs and turning technological challenges into productive opportunities.

Our story begins in the 1980s in Modena, a region renowned for its mechanical excellence, where we honed our engineering skills across various sectors, from automotive to food. However, it is in the field of PVC and aluminium window frames that we have chosen to invest all our innovative energy.

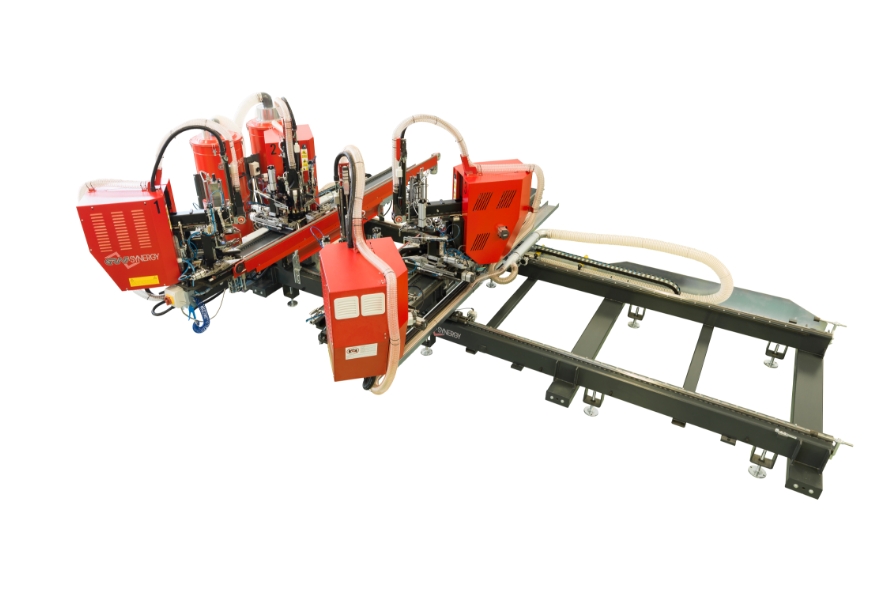

In 2012, we revolutionised the market with the SL4FF-EVO, the world’s first welder with no visible seam: a patented technology designed to ensure perfect angles without the need for manual finishing. Since then, GRAF Synergy has continued to innovate relentlessly.

From the machine to the line.

From the line to the flow.

Today, we don’t just build machinery; we design intelligent, modular, and customised production processes. We stand alongside advanced craftsmen, medium-sized enterprises, and large industrial groups with:

. High-speed CNC cutting and working centres

. Multifunction welding machines with digital control

. Robotic systems for logistics and automatic positioning

. Integrated management software for Industry 4.0

Every machine we create is designed with a clear vision: to enhance productivity, reduce human error, and improve the aesthetic quality of the finished product.

People, technology, vision: this is what drives us.

Our technical and sales team works every day to turn complex ideas into simple, user-friendly solutions. We believe that technology should be an enabling tool, not a barrier.

To achieve this, we invest every year in research, training, and development to provide our customers with increasingly high-performing, connected machines that are easy to integrate into their production ecosystem.

A global presence with Italian roots.

With over 60 countries served worldwide, dozens of installations each year, and a network of qualified local partners, GRAF Synergy has become synonymous with reliability, efficiency, and innovation in the window and door industry.

But we have not forgotten our roots: the entire production cycle takes place in Italy, in our facilities in Nonantola (MO), the beating heart of a manufacturing process that combines artisanal precision with industrial technology.

A timeline of innovations

Our promise for the future

We will continue to invest in smart machines and skilled people to establish a new production standard: faster, more flexible, and more sustainable.

If you’re looking for a technology partner rather than just a supplier, GRAF Synergy is the answer.